This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

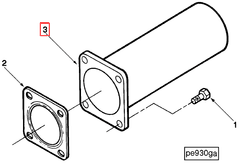

The Exhaust Outlet Tube, identified by Part #3917223, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the exhaust system, facilitating the efficient removal of exhaust gases from the engine. Cummins is renowned for its commitment to quality and innovation in manufacturing automotive components, ensuring that each part, including the Exhaust Outlet Tube, meets rigorous standards for performance and durability 1.

Function and Operation

The Exhaust Outlet Tube operates within the exhaust system by directing exhaust gases away from the engine. It connects the turbocharger to the exhaust manifold, allowing the gases to flow through the system. This tube is designed to withstand high temperatures and pressures, ensuring that the exhaust gases are efficiently channeled away from the engine compartment. Its role is vital in maintaining the overall functionality and efficiency of the exhaust system 2.

Purpose of the Exhaust Outlet Tube

In the operation of a truck, the Exhaust Outlet Tube plays a specific role by contributing to engine performance and emissions control. It ensures that exhaust gases are expelled smoothly, which helps in maintaining optimal engine operation. Additionally, by efficiently directing these gases, the tube aids in reducing emissions, thereby contributing to environmental sustainability. Its design and placement are crucial for achieving the desired balance between performance and emissions control 3.

Key Features

The primary features of the Exhaust Outlet Tube include its material construction, which is typically made from high-quality steel to withstand the harsh conditions of the exhaust system. The design elements incorporate precise engineering to ensure a secure fit and optimal performance. Unique characteristics such as heat-resistant coatings and reinforced joints enhance its functionality, providing durability and reliability in demanding environments 4.

Benefits

The advantages provided by the Exhaust Outlet Tube include improved exhaust flow, which contributes to better engine performance. By reducing backpressure within the exhaust system, the tube allows for more efficient operation of the engine. Additionally, the enhanced exhaust flow can lead to potential improvements in fuel efficiency, as the engine operates more smoothly. These benefits underscore the importance of this component in maintaining the overall efficiency and performance of the truck 5.

Installation Considerations

Proper installation of the Exhaust Outlet Tube is crucial for ensuring optimal performance and longevity. It is recommended to follow manufacturer guidelines for installation, which may include prerequisites such as ensuring the exhaust system is clean and free of obstructions. Careful attention to alignment and securing the tube in place will help prevent issues such as leaks or reduced efficiency. Regular checks post-installation can also ensure that the tube remains in optimal condition 6.

Maintenance and Troubleshooting

Routine maintenance practices for the Exhaust Outlet Tube include regular inspections for signs of wear, corrosion, or leaks. Addressing these issues promptly can prevent more significant problems down the line. Troubleshooting common issues may involve checking for proper alignment, ensuring all connections are secure, and inspecting for any damage to the tube itself. Maintaining the Exhaust Outlet Tube in good condition is key to ensuring the efficient operation of the exhaust system 7.

Environmental Impact

The Exhaust Outlet Tube contributes to emissions reduction and environmental sustainability within the context of truck operations. By efficiently directing exhaust gases away from the engine and ensuring smooth flow through the exhaust system, it plays a role in reducing harmful emissions. This component is part of Cummins’ broader commitment to producing parts that not only enhance performance but also contribute to a cleaner environment 8.

Cummins Overview

Cummins is a leading manufacturer in the automotive and heavy-duty truck industry, with a history of innovation and quality in manufacturing automotive components. The company’s reputation is built on its dedication to producing reliable, high-performance parts that meet the demanding requirements of modern engines. Cummins’ commitment to excellence is evident in every component it manufactures, including the Exhaust Outlet Tube, ensuring that customers receive parts that are both durable and efficient 9.

Exhaust Outlet Tube 3917223 Compatibility with Cummins Engines

The Exhaust Outlet Tube part number 3917223, manufactured by Cummins, is designed to fit seamlessly into specific Cummins engine models. This part is crucial for the exhaust system, ensuring that the engine operates efficiently and safely.

4B3.9 Engines

The 4B3.9 engine series benefits from the 3917223 Exhaust Outlet Tube. This part is engineered to fit perfectly within the exhaust system of the 4B3.9, providing a reliable connection that helps manage exhaust flow and reduce back pressure.

C8.3 G Engines

Similarly, the C8.3 G engine series is another beneficiary of the 3917223 Exhaust Outlet Tube. This component is tailored to integrate smoothly with the exhaust architecture of the C8.3 G, ensuring optimal performance and durability.

These engines, while differing in their specific applications and configurations, share a commonality in their need for a robust and precise exhaust outlet tube. The 3917223 part number is specifically designed to meet these needs, ensuring compatibility and reliability across the mentioned engine models 10.

Role of Part 3917223 Exhaust Outlet Tube in Engine Systems

The 3917223 Exhaust Outlet Tube is an integral component in the exhaust system of various engine setups. It serves as a conduit that facilitates the smooth transition of exhaust gases from the engine’s exhaust manifold to the exhaust plumbing. This tube is engineered to withstand high temperatures and pressures, ensuring reliable performance under demanding conditions.

In the context of exhaust connections, the 3917223 tube plays a significant role. It is typically connected to the exhaust manifold, where it collects exhaust gases from multiple cylinders. From there, it directs these gases into the exhaust plumbing, which includes components such as the catalytic converter, muffler, and tailpipe. This seamless connection is essential for maintaining the efficiency and effectiveness of the exhaust system.

The exhaust plumbing, which consists of various pipes, bends, and components designed to route exhaust gases away from the engine, relies on the 3917223 tube to ensure a secure and leak-free connection. This tube helps in reducing backpressure, which can otherwise impede engine performance. By providing a direct and unobstructed path for exhaust gases, the 3917223 tube contributes to the overall efficiency of the engine’s exhaust system.

Additionally, the 3917223 tube is often designed with features that enhance its durability and performance. These may include reinforced joints, heat shielding, and corrosion-resistant materials. Such features ensure that the tube can endure the harsh environment of the exhaust system, maintaining its integrity over time.

Conclusion

In summary, the 3917223 Exhaust Outlet Tube is a vital link in the exhaust system, ensuring that exhaust gases are efficiently routed from the engine to the exhaust plumbing. Its robust design and reliable performance make it an essential component in maintaining the overall functionality and efficiency of engine systems. Proper installation, maintenance, and understanding of its role in engine performance and emissions control are crucial for maximizing the benefits of this component.

-

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4325956, GTA855 CM558 (CM2358) G101.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4325956, GTA855 CM558 (CM2358) G101.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4325956, GTA855 CM558 (CM2358) G101.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4325956, GTA855 CM558 (CM2358) G101.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4325956, GTA855 CM558 (CM2358) G101.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4325956, GTA855 CM558 (CM2358) G101.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4325956, GTA855 CM558 (CM2358) G101.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.