This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

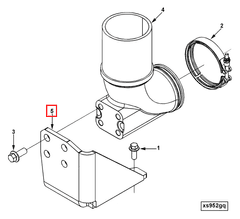

The Exhaust Outlet Connection Brace, part #3943602, is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industries. This Cummins part is integral to the exhaust systems of heavy-duty truck engines, enhancing their performance and durability. Cummins’ dedication to innovation and quality ensures that this component meets the stringent demands of heavy-duty applications 1.

Basic Concepts

Exhaust Outlet Connection Braces are engineered to support and secure the junction between the exhaust manifold and the exhaust pipe. Within the exhaust system, they provide structural integrity and stability to this crucial connection. The brace aids in maintaining the alignment and integrity of the exhaust components, which is essential for efficient exhaust flow and reduced emissions. By securing the connection, the brace also helps minimize vibrations that can cause wear and tear on the exhaust system 2.

Purpose and Role

The Exhaust Outlet Connection Brace part #3943602 is designed to enhance the efficiency and durability of the exhaust system in heavy-duty trucks. It supports the exhaust system by ensuring a secure and stable connection between the exhaust manifold and the exhaust pipe. This stability is vital for maintaining optimal exhaust flow, which in turn supports engine performance. Additionally, the brace helps reduce stress on the exhaust components, contributing to the system’s longevity.

Key Features

The Exhaust Outlet Connection Brace part #3943602 is characterized by several key features that enhance its performance and longevity. It is typically made from high-strength materials capable of withstanding the high temperatures and pressures of the exhaust system. The design of the brace includes precise engineering to ensure a perfect fit and optimal functionality. Additionally, it may feature corrosion-resistant coatings or treatments to protect against the harsh environments often encountered in heavy-duty applications.

Benefits

The advantages provided by the Exhaust Outlet Connection Brace include improved exhaust flow, which can lead to better engine performance. By securing the exhaust connection, the brace helps reduce vibrations, which can prevent premature wear on the exhaust system components. Its durable construction contributes to the overall longevity of the exhaust system. Furthermore, a well-maintained and efficiently operating exhaust system can contribute to improved fuel efficiency and reduced emissions, aligning with environmental and economic objectives.

Installation and Compatibility

Proper installation of the Exhaust Outlet Connection Brace is crucial for ensuring its effectiveness within the exhaust system. It should be correctly fitted to maintain the alignment and integrity of the exhaust components. Compatibility with various Cummins engine models is a key consideration, ensuring that the brace fits and functions as intended across different applications. Following manufacturer guidelines for installation will help achieve optimal performance and durability.

Troubleshooting and Maintenance

Identifying common issues related to the Exhaust Outlet Connection Brace, such as leaks, corrosion, or structural damage, is important for maintaining the efficiency of the exhaust system. Routine inspections can help in early detection of these issues, allowing for timely repairs or replacements. Maintenance practices, such as cleaning the brace and checking for signs of wear or damage, can prolong its lifespan and ensure optimal performance. Regular maintenance of the exhaust system, including the brace, is recommended to prevent issues and maintain engine efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation within the automotive and heavy-duty truck industries, Cummins is committed to providing high-quality products that meet the needs of its customers. The company’s focus on quality, reliability, and customer satisfaction is evident in its extensive product portfolio, which includes components like the Exhaust Outlet Connection Brace part #3943602.

Application to Cummins Engines

The Exhaust Outlet Connection Brace, part number 3943602, is a critical component in the exhaust system of certain Cummins engines. This part is designed to provide structural support and stability to the exhaust outlet connection, ensuring that it remains securely in place during operation.

Compatible Cummins Engine Models

This brace is compatible with several Cummins engine models, including:

- QSC8.3 CM554

- QSL9 CM554

In these engines, the Exhaust Outlet Connection Brace is essential for maintaining the integrity of the exhaust system. It helps prevent any undue stress or movement at the exhaust outlet, which could lead to leaks, damage, or performance issues.

The brace is typically installed during the assembly of the engine or as part of routine maintenance and repairs. Its precise fit and robust construction ensure that it can withstand the high temperatures and pressures associated with engine exhaust systems.

By securing the exhaust outlet connection, the brace contributes to the overall efficiency and longevity of the engine, making it a vital component for both new installations and ongoing maintenance.

Role of Exhaust Outlet Connection Brace in Engine Systems

The Exhaust Outlet Connection Brace, identified by part number 3943602, serves a significant function within the engine system by providing structural support and stability to the exhaust outlet connection. This component is integral in maintaining the alignment and integrity of the exhaust system, which is essential for optimal engine performance and efficiency.

Structural Support

The primary role of the Exhaust Outlet Connection Brace is to reinforce the connection between the exhaust manifold and the exhaust pipe. This brace ensures that the connection remains secure under the high temperatures and pressures generated during engine operation. By doing so, it helps prevent leaks and maintains the efficiency of the exhaust flow, which is vital for reducing backpressure and enhancing engine performance.

Thermal Management

In addition to providing structural support, the brace plays a part in thermal management. It helps distribute heat more evenly across the exhaust system, reducing the risk of thermal stress on the manifold and exhaust pipe. This even distribution of heat can prolong the lifespan of these components and ensure consistent performance over time.

Vibration Dampening

Engine operation generates significant vibrations, which can be transmitted through the exhaust system. The Exhaust Outlet Connection Brace helps dampen these vibrations, reducing the wear and tear on both the exhaust components and the engine itself. This contributes to a smoother running engine and can help prevent premature failure of exhaust system parts.

Alignment and Integrity

Proper alignment of the exhaust components is essential for efficient exhaust gas flow. The brace ensures that the exhaust manifold and pipe remain correctly aligned, even under the dynamic conditions of engine operation. This alignment is crucial for minimizing exhaust restrictions and maximizing engine efficiency.

Safety and Reliability

By ensuring a secure and stable connection, the Exhaust Outlet Connection Brace enhances the overall safety and reliability of the engine system. A well-supported exhaust system is less likely to fail unexpectedly, which is particularly important in high-performance or high-stress applications.

Conclusion

In summary, the Exhaust Outlet Connection Brace (part 3943602) is a vital component in the engine system, contributing to structural support, thermal management, vibration dampening, alignment integrity, and overall safety and reliability. Its role in maintaining the efficiency and durability of the exhaust system makes it an essential part for both new installations and ongoing maintenance in Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.