This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

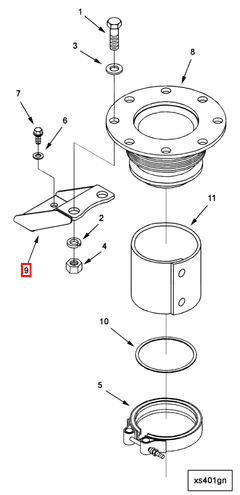

The Exhaust Connection Bracket 3957518 is a component designed by Cummins for use in the exhaust systems of commercial trucks. Its purpose is to securely connect various parts of the exhaust system, ensuring efficient and reliable operation. This bracket plays a role in maintaining the structural integrity of the exhaust system, facilitating proper exhaust flow, and contributing to the overall performance of the vehicle 2.

Function and Operation

The Exhaust Connection Bracket operates by providing a stable connection point between different sections of the exhaust system. It interacts with pipes, mufflers, and other components, ensuring they remain aligned and securely fastened. This bracket helps in managing the exhaust gases’ path from the engine to the tailpipe, playing a role in reducing vibrations and preventing leaks within the system 3.

Key Features

The design of the Exhaust Connection Bracket incorporates high-strength materials, which contribute to its durability and efficiency. It is engineered to withstand the high temperatures and pressures characteristic of exhaust systems in commercial trucks. The bracket’s construction ensures it can endure prolonged use without significant wear or failure, supporting the exhaust system’s longevity 1.

Benefits

The Exhaust Connection Bracket offers several advantages. It contributes to improved exhaust flow by ensuring a secure and stable connection between exhaust components. This efficient flow can lead to reduced emissions, as the exhaust system operates more effectively. Additionally, by maintaining the integrity of the exhaust system, the bracket plays a role in enhancing engine performance, as backpressure is managed more effectively 2.

Installation Process

Installing the Exhaust Connection Bracket requires careful attention to ensure proper fit and function. The process involves aligning the bracket with the exhaust components, securing it in place using the appropriate fasteners, and verifying that all connections are tight and secure. Tools such as wrenches and possibly a torque wrench may be necessary to complete the installation correctly. It is important to follow manufacturer guidelines to ensure safety and effectiveness 3.

Common Issues and Troubleshooting

Typical problems associated with the Exhaust Connection Bracket may include loosening over time due to vibrations or corrosion. If issues arise, inspecting the bracket and its connections for signs of wear or damage is recommended. Tightening loose fasteners or replacing corroded parts can often resolve these issues, ensuring the exhaust system continues to operate efficiently 1.

Maintenance Tips

Regular maintenance of the Exhaust Connection Bracket is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the bracket and its connections can prevent buildup that may affect performance. Additionally, ensuring all fasteners remain tight can help maintain the structural integrity of the exhaust system 2.

Compatibility and Applications

The Exhaust Connection Bracket is designed for specific types of commercial trucks and engines. Its application is tailored to fit within the exhaust systems of these vehicles, ensuring compatibility and effective performance. Detailed information on compatibility and specific applications can be found in the product documentation provided by Cummins 3.

Safety Considerations

When working with the Exhaust Connection Bracket, observing safety protocols is important. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines for installation and maintenance. Adhering to these safety considerations helps protect against injury and ensures the work is performed effectively 1.

Environmental Impact

The Exhaust Connection Bracket contributes to reducing the environmental footprint of commercial trucks through efficient exhaust management. By ensuring a secure and stable exhaust system, it plays a role in maintaining optimal exhaust flow, which can lead to reduced emissions. This efficient operation supports efforts to minimize the environmental impact of commercial vehicle operations 2.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality automotive components. With a history of innovation and excellence, Cummins has established a reputation for producing reliable and efficient parts for the automotive industry. The company’s expertise in engine and component design underscores the quality and performance of products like the Exhaust Connection Bracket 3.

Conclusion

The Exhaust Connection Bracket 3957518 by Cummins is a critical component in the exhaust systems of commercial trucks. It ensures secure connections, efficient exhaust flow, and contributes to the overall performance and environmental efficiency of the vehicle. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.