3965344

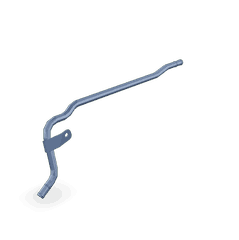

Exhaust Cooler Water Inlet Tube

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Cooler Water Inlet Tube, identified by part number 3965344, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This tube is integral to the exhaust cooling system of heavy-duty trucks, contributing to the overall efficiency and performance of the engine.

Basic Concepts

The Exhaust Cooler Water Inlet Tube is designed to facilitate the flow of coolant into the exhaust cooler. Within the exhaust cooling system, this tube interacts with various components to manage exhaust temperatures. By allowing coolant to circulate through the exhaust cooler, it helps in dissipating heat from the exhaust gases, which in turn aids in maintaining optimal engine operating temperatures and enhancing engine performance and efficiency 1.

Purpose and Role

The primary role of the Exhaust Cooler Water Inlet Tube is to ensure a steady supply of coolant to the exhaust cooler. This function is vital for reducing the temperature of exhaust gases before they exit the engine. By lowering exhaust temperatures, the tube contributes to improved engine efficiency, reduced thermal stress on engine components, and enhanced overall performance of the truck 2.

Key Features

The Exhaust Cooler Water Inlet Tube is characterized by several key features that ensure its effectiveness and durability. These include a robust construction that withstands the high pressures and temperatures of the exhaust system, precise engineering to ensure a perfect fit and function within the system, and compatibility with Cummins engines, ensuring seamless integration and performance.

Benefits

Incorporating the Exhaust Cooler Water Inlet Tube into a truck’s exhaust system offers several benefits. These include improved engine performance due to optimal exhaust temperature management, enhanced fuel efficiency as a result of more efficient engine operation, and reduced emissions, contributing to a cleaner environment. The tube’s role in maintaining engine health also leads to longer engine life and reduced maintenance costs.

Installation Process

Installing the Exhaust Cooler Water Inlet Tube requires careful attention to detail to ensure proper fit and function. The process involves disconnecting the old tube, if present, and connecting the new tube to the exhaust cooler and coolant supply lines. It is important to follow manufacturer guidelines for torque specifications and connection procedures to ensure a secure and leak-free installation.

Maintenance Tips

To ensure the longevity and optimal performance of the Exhaust Cooler Water Inlet Tube, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage, cleaning the connections to prevent blockages, and replacing the tube according to the manufacturer’s guidelines or when signs of failure are detected. Regular maintenance helps in preventing leaks and ensuring efficient coolant flow.

Troubleshooting Common Issues

Common issues with the Exhaust Cooler Water Inlet Tube may include leaks, blockages, or damage due to wear and tear. Troubleshooting these issues involves inspecting the tube and connections for visible signs of damage, checking for proper coolant flow, and ensuring all connections are secure. Addressing these issues promptly can prevent more significant problems and ensure the continued efficient operation of the exhaust cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a strong commitment to innovation, quality, and customer satisfaction, Cummins has established a reputation for excellence in the automotive industry. The company’s extensive product offerings and focus on technological advancement make it a preferred choice for heavy-duty truck applications.

Exhaust Cooler Water Inlet Tube (Part 3965344) Compatibility with Cummins Engines

The Exhaust Cooler Water Inlet Tube, part number 3965344, is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the flow of coolant into the exhaust cooler, ensuring efficient heat dissipation from the exhaust gases.

ISB CM850 Engines

The ISB CM850 engine series, known for its robust performance and reliability, integrates the Exhaust Cooler Water Inlet Tube as part of its cooling system. This part is essential for maintaining optimal engine temperatures, particularly in high-stress environments where effective cooling is paramount. The inlet tube’s design ensures a seamless connection to the engine’s exhaust system, allowing for consistent coolant flow and enhancing the engine’s overall efficiency and longevity.

Grouping of Engines

When considering the compatibility of the Exhaust Cooler Water Inlet Tube with Cummins engines, it is important to recognize that this part is specifically engineered to fit within the ISB CM850 engine series. The design and specifications of the inlet tube are tailored to meet the unique requirements of these engines, ensuring a precise fit and optimal performance. This part is not universally applicable to all Cummins engines but is crucial for those within the ISB CM850 group.

Role of Part 3965344 Exhaust Cooler Water Inlet Tube in Engine Systems

The Exhaust Cooler Water Inlet Tube, identified by part number 3965344, is an essential component in the efficient operation of engine systems that incorporate exhaust gas recirculation (EGR) and water cooling mechanisms. This component is strategically positioned to facilitate the flow of cooling water into the exhaust cooler, ensuring that the temperature of the recirculated exhaust gases is adequately managed.

In the context of the plumbing system, the Exhaust Cooler Water Inlet Tube serves as a conduit that links the water supply to the exhaust cooler. This ensures a consistent and regulated flow of cooling water, which is vital for maintaining the integrity and efficiency of the cooling process. The tube’s design allows for precise control over the water flow, which is essential for optimizing the cooling performance and preventing any potential overheating of the exhaust system.

When considering the exhaust recirculation system, the role of the Exhaust Cooler Water Inlet Tube becomes even more significant. The EGR system relies on the cooling of exhaust gases before they are reintroduced into the combustion chamber. The inlet tube ensures that the cooling water is delivered efficiently to the exhaust cooler, allowing for effective reduction of the exhaust gas temperature. This not only enhances the overall performance of the EGR system but also contributes to lower emissions by ensuring that the recirculated gases are at an optimal temperature.

Conclusion

The Exhaust Cooler Water Inlet Tube (part 3965344) plays a pivotal role in both the plumbing and exhaust recirculation systems by ensuring the efficient delivery of cooling water to the exhaust cooler. This component is integral to maintaining the desired operating temperatures within the engine system, thereby supporting both performance and emissions control.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.