This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

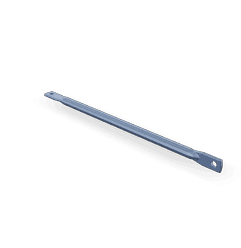

The Exhaust Outlet Connection Brace, part number 3977363, is a component manufactured by Cummins. This brace is designed to play a role in the exhaust system by providing structural support and facilitating efficient exhaust flow. Cummins, a well-established name in the automotive and commercial truck industries, ensures that this component meets high standards of quality and performance 1.

Function and Operation

The Exhaust Outlet Connection Brace operates within the exhaust system by maintaining the structural integrity of the exhaust outlet. It supports the connection between the exhaust manifold and the exhaust pipe, ensuring that the components remain securely in place. This brace also helps in directing the flow of exhaust gases, which contributes to the overall efficiency of the exhaust system. By stabilizing the connection, it reduces the likelihood of leaks and enhances the system’s performance 2.

Key Features

The design of the Exhaust Outlet Connection Brace incorporates several features that enhance its performance and durability. It is typically made from high-strength materials, such as steel or cast iron, which provide resistance to heat and mechanical stress. The brace is engineered to withstand the high temperatures and pressures present in the exhaust system. Its robust construction ensures longevity and reliability under demanding conditions 3.

Benefits

The Exhaust Outlet Connection Brace offers several advantages. It improves the stability of the exhaust system by providing a solid connection point, which reduces the risk of vibrations and potential damage to surrounding components. This stability contributes to a smoother operation of the exhaust system and can lead to enhanced overall performance of the truck. Additionally, the brace helps in maintaining the alignment of the exhaust components, which is vital for efficient exhaust gas flow and reduced emissions.

Installation Process

Installing the Exhaust Outlet Connection Brace requires careful attention to detail to ensure a secure and effective fit. The process involves several steps: first, the existing exhaust components should be inspected for any damage or wear. Next, the brace should be positioned correctly between the exhaust manifold and the exhaust pipe. Using the appropriate tools, such as wrenches and sockets, the brace should be tightened to the manufacturer’s specified torque settings. It is important to follow the recommended procedures to avoid over-tightening, which could damage the components, or under-tightening, which could lead to instability.

Maintenance and Troubleshooting

Regular maintenance of the Exhaust Outlet Connection Brace is important to ensure its continued performance. This includes periodic inspections for signs of wear, corrosion, or damage. Common indicators of issues may include unusual vibrations, changes in exhaust noise, or visible cracks in the brace. If any problems are detected, it is advisable to address them promptly to prevent further damage. Troubleshooting steps may involve tightening loose connections, replacing worn components, or seeking professional assistance for more complex issues.

Safety Considerations

When working with the Exhaust Outlet Connection Brace, it is important to follow safety precautions to protect oneself and ensure the proper functioning of the component. This includes wearing appropriate protective equipment, such as gloves and safety glasses, to guard against heat and potential debris. Additionally, ensuring that the exhaust system is cool before beginning any work can help prevent burns and other injuries. Following the manufacturer’s guidelines and recommendations for installation and maintenance is crucial for safe and effective use.

Environmental Impact

The production, use, and disposal of the Exhaust Outlet Connection Brace have environmental implications. Cummins is committed to minimizing its environmental footprint through various initiatives. This includes using sustainable materials where possible, implementing efficient manufacturing processes, and ensuring that components are designed for longevity to reduce the need for frequent replacements. Additionally, Cummins encourages proper recycling and disposal practices to mitigate the environmental impact of its products.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the automotive and commercial truck industries. The company offers a wide range of products and services designed to meet the needs of customers around the world, emphasizing reliability, performance, and customer satisfaction.

Conclusion

The Exhaust Outlet Connection Brace (3977363) by Cummins is a vital component in the exhaust system, providing structural support, vibration dampening, thermal management, and alignment maintenance. Its role in enhancing the durability, performance, and reliability of the exhaust system underscores its importance in engine systems. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this component.

-

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.