4006336

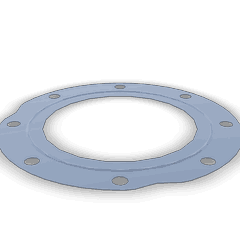

Exhaust Outlet Connection Gasket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Outlet Connection Gasket, identified by Part #4006336, is a component manufactured by Cummins, a leading name in diesel engine technology. This gasket plays a significant role in the exhaust systems of heavy-duty trucks, ensuring a secure and efficient connection between the exhaust manifold and the exhaust pipe. Cummins, known for its robust and reliable engine components, provides this gasket as part of its extensive lineup of parts designed to enhance the performance and durability of diesel engines 1.

Function and Operation

The Exhaust Outlet Connection Gasket operates within the exhaust system by creating a seal between the exhaust manifold and the exhaust pipe. This seal is vital for maintaining the integrity of the exhaust flow, preventing leaks that could lead to decreased engine performance and increased emissions. The gasket is designed to withstand high temperatures and pressures, ensuring a consistent seal under varying operating conditions 2.

Key Features

The Exhaust Outlet Connection Gasket is characterized by its material composition and design specifications. It is typically made from high-temperature resistant materials, ensuring durability and longevity in demanding environments. The gasket’s design includes precise dimensions to fit snugly between the exhaust manifold and pipe, enhancing its sealing capabilities. Additionally, it may feature unique attributes such as heat-resistant coatings or reinforced edges to further improve performance and durability 3.

Benefits

The use of the Exhaust Outlet Connection Gasket offers several benefits. It improves the sealing of the exhaust system, which can lead to a reduction in emissions and enhanced engine performance. By maintaining a tight seal, the gasket contributes to the overall efficiency of the exhaust system, ensuring that exhaust gases are directed away from the engine compartment effectively. This can also help in maintaining optimal engine temperatures and reducing the risk of exhaust-related issues 4.

Installation Process

Proper installation of the Exhaust Outlet Connection Gasket is crucial for its effective function. The process involves cleaning the mating surfaces of the exhaust manifold and pipe to ensure a smooth and even fit. The gasket should be positioned correctly, aligning with the bolt holes and ensuring it is not twisted or misaligned. Tightening the bolts in a specified sequence can help achieve an even seal. It is important to avoid over-tightening, which could damage the gasket, and to check for any signs of leaks after installation.

Maintenance and Troubleshooting

Regular maintenance of the Exhaust Outlet Connection Gasket involves inspecting it for signs of wear or damage. Common issues include leaks, which can be identified by unusual noises or a change in exhaust smell. If a leak is detected, the gasket may need to be replaced. Troubleshooting should involve checking the condition of the mating surfaces and ensuring that the gasket is installed correctly. Keeping the gasket and surrounding components clean can also help in maintaining its performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a strong reputation for innovation, quality, and reliability in the automotive industry. The company’s product portfolio includes engines, filtration systems, powertrain-related components, and emission solutions, catering to various industries such as transportation, construction, and power generation. Cummins’ commitment to excellence is reflected in its extensive range of high-quality components, designed to meet the demanding requirements of modern engines.

Cummins Exhaust Outlet Connection Gasket 4006336

The Cummins Exhaust Outlet Connection Gasket, part number 4006336, is a critical component in ensuring the integrity of the exhaust system for several Cummins engines. This gasket is designed to provide a secure seal between the exhaust outlet and the engine, preventing leaks and maintaining optimal performance.

Application in Cummins Engines

QSK78 CM500

The QSK78 CM500 engine is a high-performance, heavy-duty diesel engine known for its reliability and efficiency. The Exhaust Outlet Connection Gasket 4006336 is specifically engineered to fit this engine, ensuring a tight seal that prevents exhaust gases from escaping. This is crucial for maintaining the engine’s efficiency and reducing emissions.

QSK50 Series

The QSK50 series includes a range of engines that are widely used in various applications, from marine to industrial use. The Exhaust Outlet Connection Gasket 4006336 is compatible with these engines, providing a reliable seal that is essential for the proper functioning of the exhaust system. This gasket helps in maintaining the structural integrity of the engine and ensures that the exhaust system operates efficiently.

QSK60 Series

The QSK60 series engines are known for their robust design and high power output. The Exhaust Outlet Connection Gasket 4006336 is an essential part for these engines, ensuring that the exhaust system remains sealed and efficient. This gasket is designed to withstand the high temperatures and pressures associated with these engines, providing a long-lasting solution for exhaust sealing.

QSK95 Series

The QSK95 series engines are among the most powerful and reliable engines in the Cummins lineup. The Exhaust Outlet Connection Gasket 4006336 is a critical component for these engines, ensuring that the exhaust system remains sealed and efficient. This gasket is designed to handle the extreme conditions these engines operate under, providing a durable and reliable sealing solution.

Role of Part 4006336 Exhaust Outlet Connection Gasket in Engine Systems

The Exhaust Outlet Connection Gasket, part 4006336, is an essential component in ensuring the efficient and reliable operation of engine systems, particularly in arrangements involving turbochargers.

In turbocharged engine systems, the gasket is positioned between the exhaust manifold and the turbocharger’s turbine housing. This placement is vital for maintaining a sealed connection, which is necessary for directing exhaust gases effectively. The gasket ensures that exhaust gases flow smoothly from the engine’s cylinders through the manifold and into the turbocharger. This efficient flow is important for maximizing the turbocharger’s performance, as it relies on the momentum of exhaust gases to spin the turbine and compress incoming air.

Additionally, the gasket plays a significant role in preventing exhaust gas leaks. Any leakage can lead to a loss of exhaust pressure, which directly affects the turbocharger’s efficiency. A well-sealed connection ensures that the turbocharger receives the full force of the exhaust gases, allowing it to operate at optimal levels and provide the necessary boost for enhanced engine performance.

Furthermore, the gasket contributes to the overall durability of the engine system. By providing a robust seal, it helps in reducing the risk of damage to surrounding components due to excessive heat or pressure. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions.

Conclusion

The Exhaust Outlet Connection Gasket, part 4006336, is integral to the proper functioning of turbocharged engine systems. It ensures efficient exhaust gas flow, prevents leaks, and contributes to the durability and performance of the engine. By using this Cummins part, engine operators can ensure that their engines maintain optimal performance and efficiency.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.