4006931

Exhaust Outlet Connection

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

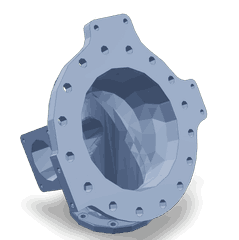

The Exhaust Outlet Connection 4006931 by Cummins is a component designed to facilitate the efficient transfer of exhaust gases from the engine to the exhaust system in commercial trucks. Its purpose is to ensure a secure and leak-free connection, contributing to the overall performance and efficiency of the vehicle. This part plays a role in maintaining the integrity of the exhaust system, which is vital for engine operation and emissions control.

Basic Concepts of Exhaust Outlet Connections

An Exhaust Outlet Connection serves as the interface between the engine and the exhaust system. Its primary function is to direct exhaust gases away from the engine, allowing for the safe and efficient operation of the vehicle. By providing a sealed connection, it prevents the escape of harmful gases and contributes to the overall performance and emissions efficiency of the truck’s engine 1.

Role of the Exhaust Outlet Connection in Truck Operation

The Exhaust Outlet Connection is specifically engineered to connect the exhaust manifold to the exhaust pipe in Cummins engines. It plays a role in the exhaust system by ensuring that exhaust gases are directed away from the engine compartment efficiently. This connection contributes to engine efficiency by maintaining backpressure within the exhaust system, which is necessary for optimal turbocharger performance. Additionally, it aids in emissions control by ensuring that exhaust gases are properly channeled through the emissions treatment system 2.

Key Features of the Exhaust Outlet Connection

The Exhaust Outlet Connection is constructed from high-quality materials that offer durability and resistance to the high temperatures and pressures of the exhaust system. Its design includes features that enhance sealing capabilities, such as precision-machined surfaces and robust gasket materials. These characteristics contribute to the connection’s performance and longevity, ensuring reliable operation under demanding conditions 3.

Benefits of Using the Exhaust Outlet Connection

Utilizing the Exhaust Outlet Connection offers several advantages. It contributes to improved engine performance by ensuring a secure and efficient exhaust gas flow. The connection’s durable construction enhances the longevity of the exhaust system, reducing the need for frequent replacements. Additionally, it aids in compliance with emissions regulations by facilitating proper exhaust gas management and treatment 4.

Troubleshooting and Maintenance Suggestions

Common issues with the Exhaust Outlet Connection may include leaks or damage due to thermal stress. Regular inspection for signs of wear, corrosion, or gasket failure is recommended to ensure optimal performance. Maintenance practices should include checking for proper torque on fasteners and ensuring that gaskets are in good condition. Addressing issues promptly can prevent more significant problems and ensure the longevity of the exhaust system.

Integration with Cummins Engines

The Exhaust Outlet Connection is designed to integrate seamlessly with Cummins engines. It features specific compatibility considerations that ensure a precise fit and function within the exhaust system. This integration is crucial for maintaining the performance and efficiency of Cummins engines, as it ensures that exhaust gases are managed effectively throughout the system.

Environmental and Regulatory Considerations

The Exhaust Outlet Connection plays a role in helping trucks meet environmental standards and regulatory requirements for emissions. By ensuring a secure and efficient exhaust gas flow, it contributes to the effectiveness of the emissions treatment system. This part may include features or certifications that demonstrate compliance with relevant environmental and regulatory standards, highlighting Cummins’ commitment to sustainable and responsible manufacturing practices.

Historical Development and Technological Advancements

The development of Exhaust Outlet Connections has seen significant technological advancements over the years. These improvements have led to the current design of the Exhaust Outlet Connection, which incorporates materials and construction techniques that enhance performance, durability, and emissions efficiency. These advancements have contributed to the overall improvement in truck performance and efficiency, reflecting the ongoing innovation in automotive technology.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a history of innovation and quality in the automotive industry. The company’s core competencies include the design and production of high-performance engines, as well as a commitment to sustainability and environmental responsibility. Cummins’ role in the industry is characterized by a dedication to advancing technology and providing reliable, efficient solutions for commercial vehicle applications.

Application in Cummins Engines

-

QSK78 Series

- The QSK78 series engines, known for their robust performance and durability, integrate the Exhaust Outlet Connection to maintain the integrity of the exhaust system. This connection is essential for handling the high-pressure and high-temperature exhaust gases, ensuring the longevity and efficiency of the engine.

-

CM500 Series

- Similarly, the CM500 series engines, which are designed for a variety of industrial and marine applications, utilize the Exhaust Outlet Connection. This part plays a role in the exhaust system by providing a secure and leak-free connection, which is vital for the optimal performance of the engine.

In both series, the Exhaust Outlet Connection is engineered to withstand the demanding conditions of the exhaust system, ensuring that the engine operates at peak efficiency while minimizing the risk of leaks and other potential issues.

Role of Part 4006931 Exhaust Outlet Connection in Engine Systems

The Exhaust Outlet Connection, identified by part number 4006931, is integral to the efficient operation of various engine components. Its primary function is to facilitate the smooth transition of exhaust gases from the engine to subsequent systems, ensuring optimal performance and reduced emissions.

Integration with Engine Arrangement

In the overall engine arrangement, the Exhaust Outlet Connection serves as a vital junction. It connects the engine’s exhaust manifold to other components such as the catalytic converter, muffler, and tailpipe. This connection ensures that exhaust gases are directed away from the engine compartment efficiently. The proper sealing and secure fitting provided by part 4006931 are essential for maintaining the integrity of the exhaust system, preventing leaks that could lead to performance issues or increased emissions.

Interaction with Turbocharger

When integrated into systems equipped with a turbocharger, the Exhaust Outlet Connection plays a role in enhancing engine performance. The turbocharger relies on the flow of exhaust gases to spin the turbine, which in turn drives the compressor to intake more air into the engine. Part 4006931 ensures that the exhaust gases are channeled effectively to the turbocharger, maximizing its efficiency.

The connection must be robust to withstand the high temperatures and pressures associated with turbocharged engines. It also helps in maintaining the backpressure levels required for the turbocharger to operate within its optimal range, thereby contributing to improved throttle response and overall engine efficiency.

Conclusion

The Exhaust Outlet Connection 4006931 by Cummins is a critical component in the exhaust systems of various Cummins engines, ensuring efficient and reliable operation. Its design and construction are tailored to withstand the demanding conditions of the exhaust system, contributing to engine efficiency, emissions control, and compliance with environmental regulations. Regular maintenance and prompt troubleshooting are essential to ensure the longevity and optimal performance of this part.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.