4324382

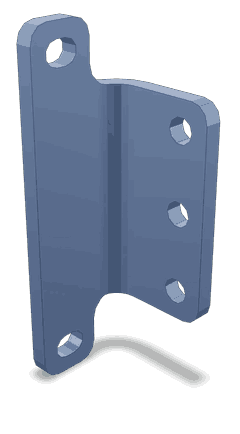

Exhaust Collector Connection Brace

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Collector Connection Brace, identified by part number 4324382, is a component designed by Cummins for use in the exhaust systems of heavy-duty trucks. This brace serves to reinforce the connection between the exhaust manifold and the exhaust collector, ensuring stability and integrity within the exhaust system.

Function and Operation

The Exhaust Collector Connection Brace operates by providing additional support to the connection point between the exhaust manifold and the exhaust collector. This reinforcement helps maintain the alignment and structural integrity of these components under the high temperatures and pressures typical of heavy-duty truck exhaust systems. It interacts with the exhaust manifold, collector, and potentially other components like the turbocharger, ensuring a secure and efficient exhaust flow 1.

Purpose of the Exhaust Collector Connection Brace

The primary role of the Exhaust Collector Connection Brace is to enhance the durability and reliability of the exhaust system. By stabilizing the connection between the exhaust manifold and collector, it helps prevent leaks and reduces the risk of component failure due to thermal expansion and contraction, vibrations, and other operational stresses.

Key Features

The Exhaust Collector Connection Brace is constructed from high-strength materials, typically steel or a steel alloy, to withstand the harsh conditions of the exhaust system. Its design includes features such as precision-machined mounting points and a robust frame structure to ensure a secure fit and long-lasting performance. Additionally, the brace may incorporate heat-resistant coatings or treatments to further enhance its durability in high-temperature environments.

Benefits

The installation of the Exhaust Collector Connection Brace offers several advantages. It contributes to improved exhaust flow by maintaining the integrity of the exhaust path, which can lead to better engine performance. Additionally, by reducing the likelihood of exhaust leaks, it helps in lowering emissions and ensuring compliance with environmental regulations. The brace also enhances the overall durability of the exhaust system, potentially reducing maintenance costs and downtime.

Installation Process

Installing the Exhaust Collector Connection Brace requires careful attention to detail. The process typically involves the following steps:

- Ensure the engine is cool and the exhaust system is free of pressure.

- Remove any existing components that may obstruct the installation of the brace.

- Align the brace with the mounting points on the exhaust manifold and collector.

- Secure the brace using the appropriate fasteners, ensuring they are tightened to the manufacturer’s specified torque settings.

- Inspect the installation for proper fit and alignment, making any necessary adjustments.

Common Issues and Troubleshooting

Typical problems associated with the Exhaust Collector Connection Brace may include loosening of fasteners, corrosion, or damage due to extreme heat. Troubleshooting methods involve:

- Regularly inspecting the brace and fasteners for signs of wear or corrosion.

- Tightening or replacing fasteners as necessary to maintain a secure connection.

- Applying heat-resistant coatings or treatments to protect against corrosion and heat damage.

Maintenance Tips

To ensure the longevity and optimal performance of the Exhaust Collector Connection Brace, consider the following maintenance practices:

- Perform regular inspections during routine maintenance checks.

- Clean the brace and surrounding components to remove any buildup of soot or debris.

- Monitor for any signs of wear, corrosion, or damage, and address issues promptly to prevent further deterioration.

Compatibility and Applications

The Exhaust Collector Connection Brace is designed for use in specific models and series of heavy-duty trucks equipped with Cummins engines. Compatibility information, including specific truck models and engine series, should be consulted to ensure proper fit and function.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s product range includes diesel and natural gas engines, as well as related technologies and services, catering to a wide array of applications from on-highway to off-highway and stationary power 2.

Exhaust Collector Connection Brace for Cummins Engines

The Exhaust Collector Connection Brace, part number 4324382, is a critical component in the exhaust system of certain Cummins engines. This part is designed to maintain the structural integrity of the exhaust collector, ensuring that it remains securely attached to the engine.

Application in Cummins Engines

QSK95 CM2350 K111 and K113

The Exhaust Collector Connection Brace is specifically engineered to fit the QSK95 CM2350 K111 and K113 engines. These engines are part of Cummins’ QSK95 series, known for their robust performance and reliability in various industrial applications. The brace plays a pivotal role in these engines by:

- Securing the Exhaust Collector: It ensures that the exhaust collector is firmly attached to the engine, preventing any movement or misalignment that could lead to performance issues or damage.

- Maintaining Exhaust Flow: By keeping the exhaust collector in place, the brace helps maintain optimal exhaust flow, which is crucial for the engine’s efficiency and longevity.

- Reducing Vibration: The brace helps to absorb and dissipate vibrations from the exhaust system, reducing the overall stress on the engine components and enhancing durability.

The Exhaust Collector Connection Brace is a testament to Cummins’ commitment to quality and precision engineering, ensuring that these engines operate at peak performance.

Role of Part 4324382 Exhaust Collector Connection Brace in Engine Systems

The 4324382 Exhaust Collector Connection Brace is an essential component in the arrangement of exhaust systems, particularly when integrated with turbochargers. This brace serves to securely connect the exhaust collector to the turbocharger, ensuring a stable and efficient transfer of exhaust gases.

In turbocharged engine systems, the brace plays a significant role in maintaining the structural integrity of the exhaust path. It helps to absorb and distribute the vibrational forces generated by the turbocharger, which operates at high speeds to compress air entering the engine. This not only enhances the durability of the exhaust system but also contributes to the overall performance and reliability of the engine.

Furthermore, the 4324382 brace aids in optimizing the flow of exhaust gases from the engine cylinders to the turbocharger. By providing a rigid connection, it minimizes the risk of leaks and ensures that exhaust gases are directed efficiently, which is vital for maximizing turbocharger efficiency and engine power output.

In summary, the 4324382 Exhaust Collector Connection Brace is integral to the effective operation of turbocharged engine systems, facilitating a robust and efficient exhaust gas flow while withstanding the dynamic forces at play.

Conclusion

The Exhaust Collector Connection Brace (part number 4324382) by Cummins is a vital component in the exhaust systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in reinforcing the connection between the exhaust manifold and collector, maintaining exhaust flow, and reducing vibrations underscores its importance in ensuring the durability, efficiency, and reliability of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.