This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

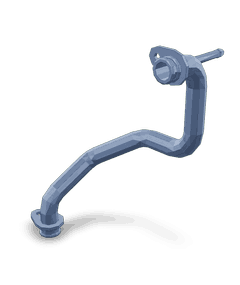

The Exhaust Cooler Water Outlet Tube, part number 4360087, is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industry. This tube is essential for the cooling system of heavy-duty truck engines, ensuring efficient coolant flow and temperature regulation, which are critical for maintaining engine performance and longevity 1.

Function and Operation

This Cummins part operates within the engine cooling system by directing coolant from the exhaust cooler to other parts of the engine. It ensures that the coolant, after absorbing heat from the exhaust gases, is efficiently circulated to help manage engine temperature. This process is vital for dissipating heat away from the engine components, thereby maintaining optimal operating temperatures 2.

Purpose of the Exhaust Cooler Water Outlet Tube

In the operation of a truck, the Exhaust Cooler Water Outlet Tube contributes to engine efficiency and performance by ensuring that the coolant is effectively routed through the cooling system. This helps in maintaining the engine’s temperature within a specified range, which is necessary for the engine to operate efficiently and reliably. Proper temperature management also aids in reducing thermal stress on engine components, potentially extending their lifespan 3.

Key Features

The Exhaust Cooler Water Outlet Tube is characterized by its robust material composition, typically made from durable metals or high-grade plastics to withstand the high temperatures and pressures within the cooling system. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance its durability and resistance to wear and tear.

Benefits

The advantages provided by the Exhaust Cooler Water Outlet Tube include improved engine cooling efficiency, which is vital for maintaining engine performance under various operating conditions. Its durable construction contributes to the longevity of the cooling system components. Furthermore, effective coolant management can lead to potential fuel efficiency gains by ensuring the engine operates within its optimal temperature range.

Installation and Compatibility

For the proper installation of the Exhaust Cooler Water Outlet Tube, it is important to follow manufacturer guidelines to ensure compatibility with specific truck models. This may involve preparing the installation site, ensuring all connections are secure, and verifying that the tube is correctly aligned within the cooling system. Compatibility with the truck’s make and model is crucial for optimal performance and should be verified prior to installation.

Maintenance and Troubleshooting

Routine maintenance practices for the Exhaust Cooler Water Outlet Tube include regular inspections for signs of wear, leaks, or corrosion. Ensuring that all connections are tight and that the tube is free from obstructions can help maintain its effectiveness. Troubleshooting common issues may involve checking for leaks, assessing the condition of the tube, and ensuring that the coolant flow is not restricted. Addressing these issues promptly can help prevent more significant problems within the engine cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to manufacturing high-quality components for commercial vehicles. Their products are known for reliability, efficiency, and durability, making them a preferred choice for heavy-duty truck applications.

Application in ISV Engines

In the context of ISV (Intelligent Shift Vehicle) engines, the Exhaust Cooler Water Outlet Tube is integral to the exhaust cooling system. This system is particularly important in high-performance or heavy-duty engines where managing exhaust heat is crucial for longevity and efficiency. The tube connects the exhaust cooler to the engine’s water jacket, allowing coolant to flow through and absorb heat from the exhaust gases.

Compatibility with Cummins Engines

Cummins engines, known for their durability and performance, often incorporate advanced cooling systems to handle the high thermal loads generated during operation. The Exhaust Cooler Water Outlet Tube (4360087) is specifically engineered to fit seamlessly into these systems, ensuring reliable performance and longevity.

Grouping of Compatible Engines

- ISV Engines: The Exhaust Cooler Water Outlet Tube is designed to fit various models within the ISV engine range. This includes engines used in commercial and industrial applications where robust cooling solutions are essential.

- Heavy-Duty Engines: Cummins heavy-duty engines benefit from this part, as it helps maintain optimal operating temperatures, reducing the risk of overheating and extending engine life.

Role of Part 4360087 in Engine Systems

The Exhaust Cooler Water Outlet Tube, identified by part number 4360087, is an integral component in the efficient operation of engine systems that incorporate exhaust gas recirculation (EGR) and exhaust after-treatment technologies. This tube facilitates the circulation of cooling water from the exhaust cooler, ensuring that the temperature of the recirculated exhaust gases is adequately managed.

In the context of EGR systems, the Exhaust Cooler Water Outlet Tube plays a significant role in maintaining optimal temperatures. The EGR system works by recirculating a portion of the engine’s exhaust gas back to the engine cylinders. This process reduces nitrogen oxides (NOx) emissions by lowering the combustion temperature. The Exhaust Cooler Water Outlet Tube ensures that the recirculated gases are cooled sufficiently before they are reintroduced into the combustion process. This cooling is vital for preserving engine efficiency and reducing emissions.

Additionally, in exhaust after-treatment systems, the Exhaust Cooler Water Outlet Tube contributes to the overall effectiveness of components such as selective catalytic reduction (SCR) systems and diesel particulate filters (DPF). By regulating the temperature of the exhaust gases, the tube helps to create an environment where these after-treatment devices can operate at peak efficiency. Proper temperature management is essential for the chemical reactions that reduce harmful emissions and for the regeneration processes that maintain the functionality of the DPF.

Conclusion

The Exhaust Cooler Water Outlet Tube (part 4360087) is a key element in the thermal management of exhaust systems. Its role in cooling recirculated exhaust gases ensures that both EGR and after-treatment systems function effectively, contributing to lower emissions and improved engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.