This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Recirculation Cooler Kit (Part #4376342) by Cummins is engineered to enhance the efficiency and performance of the exhaust system in commercial trucks. This kit is instrumental in reducing emissions and improving engine performance by cooling the recirculated exhaust gases before they are reintroduced into the combustion process.

Basic Concepts of Exhaust Recirculation Cooler Kits

Exhaust Recirculation Cooler Kits function by reducing nitrogen oxides (NOx) emissions through the recirculation of a portion of the exhaust gases back into the engine’s intake. The cooler kit is integrated into the exhaust system and works by lowering the temperature of these recirculated gases. This cooling process reduces the formation of NOx during combustion. The kit interacts with the engine’s exhaust gas recirculation (EGR) system, ensuring that the gases are at an optimal temperature before they are mixed with the incoming air-fuel mixture 1.

Purpose and Role in Truck Operation

The primary role of the Exhaust Recirculation Cooler Kit (Part #4376342) is to enhance the efficiency of the EGR system in commercial trucks. By cooling the recirculated exhaust gases, the kit aids in reducing emissions, particularly NOx, which is a significant contributor to air pollution. Additionally, the cooler kit contributes to improved engine performance by ensuring that the recirculated gases do not overheat the combustion process, thereby maintaining optimal engine operation and fuel efficiency 2.

Key Features

The Exhaust Recirculation Cooler Kit (Part #4376342) is designed with several key features that enhance its functionality. The kit ensures efficient heat exchange, effectively cooling the exhaust gases. It is constructed from durable materials that withstand the high temperatures and pressures of the exhaust system. Unique attributes of the kit include its compact design, which allows for easy integration into existing exhaust systems, and its robust construction, which ensures longevity and reliability in demanding commercial truck applications 3.

Benefits

Utilizing the Exhaust Recirculation Cooler Kit (Part #4376342) offers several benefits. It contributes to improved engine efficiency by ensuring that the recirculated exhaust gases are at an optimal temperature, which enhances combustion efficiency. The kit also plays a role in reducing emissions, particularly NOx, helping commercial truck operators meet stringent environmental regulations. Additionally, by improving engine performance and reducing emissions, the kit can lead to potential cost savings for fleet operators through improved fuel efficiency and reduced maintenance costs 4.

Installation Process

Installing the Exhaust Recirculation Cooler Kit (Part #4376342) involves several steps to ensure proper integration into the exhaust system. Begin by locating the appropriate position in the exhaust system where the cooler kit will be installed. Follow the manufacturer’s instructions for disconnecting the existing exhaust components and connecting the cooler kit in its place. Ensure all connections are secure and that the kit is properly aligned with the exhaust flow. Finally, conduct a thorough inspection to confirm that the installation is correct and that there are no leaks in the system.

Troubleshooting and Maintenance

To troubleshoot common issues with the Exhaust Recirculation Cooler Kit (Part #4376342), start by checking for any signs of leaks in the exhaust system, as these can indicate a problem with the installation. Ensure that all connections are tight and that the kit is properly aligned. Regular maintenance involves inspecting the cooler kit for any signs of wear or damage, cleaning any buildup of soot or debris, and ensuring that the cooling fins are not obstructed. Following these maintenance tips will help ensure optimal performance and longevity of the kit.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. The company’s product range includes engines and components for on-highway and off-highway applications, as well as power generation and industrial solutions. Cummins’ dedication to quality and performance has established it as a trusted name in the industry.

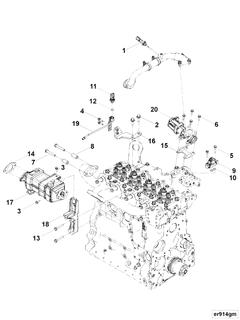

Components of Cummins Exhaust Recirculation Cooler Kit 4376342

The Cummins Exhaust Recirculation Cooler Kit 4376342 is a comprehensive assembly designed to facilitate the efficient recirculation of exhaust gases back into the engine’s intake system. This kit comprises several critical components, each playing a vital role in ensuring the system’s integrity and performance.

Connection Gasket (4932615)

The Connection Gasket is essential for creating a secure and leak-proof seal between various components within the exhaust recirculation system. Its primary function is to prevent the escape of exhaust gases, ensuring that they are effectively recirculated back into the engine. This gasket is typically positioned at the junctions where different parts of the system connect, such as between the cooler and the manifold.

Sealing Washer (4934278)

The Sealing Washer is another critical component that ensures the tightness of connections within the system. It is often used in conjunction with bolts and nuts to provide an additional layer of sealing, particularly in areas where fluid or gas leakage could occur. This washer is vital for maintaining the system’s pressure integrity and preventing any unwanted emissions.

O Ring Seal (5294926)

The O Ring Seal is a flexible, toroidal joint that creates a seal between two or more mating parts. In the context of the Exhaust Recirculation Cooler Kit, the O Ring Seal is used to ensure that connections, such as those between the cooler and its housing, remain airtight. This component is crucial for maintaining the efficiency of the recirculation process by preventing any bypass of exhaust gases.

Exhaust Gas Recirculation Cooler (5312289)

The Exhaust Gas Recirculation Cooler is the core component of the kit. Its function is to cool the recirculated exhaust gases before they enter the engine’s intake system. This cooling process reduces the temperature of the gases, which helps to lower NOx emissions and improve overall engine performance. The cooler is typically a heat exchanger that uses either air or engine coolant to achieve the desired temperature reduction.

Exhaust Manifold Gasket (5447591)

The Exhaust Manifold Gasket is positioned between the exhaust manifold and the engine block or other components. Its role is to seal the connection, preventing exhaust gases from leaking out of the manifold. In the Exhaust Recirculation Cooler Kit, this gasket ensures that the gases are directed into the recirculation system rather than escaping into the atmosphere.

Each of these components works in concert to ensure the Exhaust Recirculation Cooler Kit functions as intended, providing a reliable and efficient means of recirculating exhaust gases to reduce emissions and enhance engine performance.

Conclusion

The Exhaust Recirculation Cooler Kit (Part #4376342) by Cummins is a vital component in the effort to reduce emissions and improve engine performance in commercial trucks. Through its efficient cooling of recirculated exhaust gases, this part not only helps in meeting environmental regulations but also contributes to the overall efficiency and longevity of the engine. Proper installation, regular maintenance, and understanding of its components are key to maximizing the benefits of this Cummins part.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.