This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Gas Recirculation (EGR) Cooler 4937100 by Cummins is designed to enhance the operation of commercial trucks by reducing emissions and improving engine efficiency. This part cools the exhaust gases before they are recirculated back into the engine, which helps in lowering the combustion temperature and reducing the formation of nitrogen oxides (NOx) and other pollutants 2.

Basic Concepts of Exhaust Gas Recirculation Coolers

Exhaust Gas Recirculation Coolers operate by recirculating a portion of the exhaust gases back into the engine’s intake. Cooling these gases before reintroduction helps reduce the peak combustion temperature, leading to lower NOx emissions and more efficient engine operation. The cooler works in conjunction with the EGR valve and other components to manage the flow and temperature of the recirculated gases 4.

Role of the 4937100 Exhaust Gas Recirculation Cooler in Truck Operation

The 4937100 EGR Cooler ensures that the recirculated exhaust gases are at an optimal temperature before entering the engine. This cooler interacts with the EGR valve, the intake manifold, and the exhaust system. By maintaining the correct temperature of the recirculated gases, the 4937100 EGR Cooler contributes to smoother engine performance, reduced emissions, and improved fuel efficiency 3.

Key Features of the 4937100 Exhaust Gas Recirculation Cooler

The 4937100 EGR Cooler is characterized by its robust design and the use of high-quality materials. It features a compact yet efficient structure that allows for effective heat exchange. The cooler is constructed from durable materials that can withstand the high temperatures and pressures of the exhaust system. Additionally, it includes advanced sealing technologies to prevent leaks and ensure reliable operation 1.

Benefits of Using the 4937100 Exhaust Gas Recirculation Cooler

The use of the 4937100 EGR Cooler offers several advantages. It contributes to significant reductions in NOx emissions, helping trucks meet stringent environmental regulations. Additionally, by improving the efficiency of the EGR system, the cooler can lead to better fuel economy. Fleet operators may also experience cost savings due to the cooler’s durability and reduced maintenance requirements 2.

Installation and Integration

Proper installation of the 4937100 EGR Cooler involves several considerations. It is important to ensure that the cooler is correctly positioned within the engine system to allow for optimal flow and cooling of the exhaust gases. Any necessary preparations, such as cleaning the installation area and checking for compatibility with existing components, should be performed. Following the manufacturer’s guidelines for installation will help ensure the cooler functions effectively 3.

Maintenance and Troubleshooting

Routine maintenance of the 4937100 EGR Cooler is vital for its longevity and performance. Regular inspections for signs of wear, corrosion, or leaks are recommended. Cleaning the cooler to remove any buildup of soot or debris will help maintain its efficiency. Troubleshooting common issues, such as reduced cooling efficiency or leaks, may involve checking the cooler’s seals, connections, and overall condition. Prompt attention to any issues will help prevent more significant problems down the line 1.

Regulatory Compliance and Environmental Impact

The 4937100 EGR Cooler assists trucks in meeting emissions regulations by significantly reducing NOx emissions. Compliance with standards such as the Environmental Protection Agency (EPA) regulations is facilitated by the effective operation of the EGR system, of which the cooler is a key component. By contributing to lower emissions, the cooler also supports environmental sustainability efforts in the commercial trucking industry 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves commercial truck markets with reliable and efficient products. The company’s dedication to advancing technology and meeting customer needs underscores its position as a leader in the industry 3.

Compatibility with Cummins Engines

The Exhaust Gas Recirculation (EGR) Cooler, identified by part number 4937100, is designed to cool the recirculated exhaust gases before they are reintroduced into the engine’s intake manifold, thereby reducing the formation of nitrogen oxides (NOx) and improving overall engine efficiency.

Compatibility with Cummins Engines

- ISB (Chrysler) Engines: The EGR Cooler part 4937100 is specifically engineered to fit seamlessly with the ISB engines used in Chrysler vehicles. These engines are known for their robust performance and reliability, making the EGR Cooler an essential part for maintaining optimal engine operation.

- Other Cummins Engines: While the primary focus here is on the ISB engines, it is worth noting that the EGR Cooler part 4937100 is also compatible with a range of other Cummins engines. This compatibility ensures that the EGR system functions effectively across different engine models, contributing to reduced emissions and enhanced engine performance.

The integration of the EGR Cooler into the engine system is a testament to Cummins’ commitment to providing high-quality, reliable components that meet stringent environmental standards. This part’s design and functionality are crucial for the efficient operation of the EGR system, ensuring that the engine performs at its best while minimizing its environmental impact 3.

Role of Part 4937100 Exhaust Gas Recirculation Cooler in Engine Systems

The Exhaust Gas Recirculation (EGR) Cooler, identified by part number 4937100, is an integral component within the EGR system of modern engine designs. Its primary function is to reduce the temperature of the exhaust gases that are recirculated back into the intake manifold. This process is essential for lowering nitrogen oxide (NOx) emissions, which are a significant contributor to air pollution and smog formation.

When the EGR system is activated, a portion of the exhaust gases is diverted from the exhaust manifold and routed through the EGR Cooler. The cooler is typically positioned in the EGR path to ensure that the gases are cooled before they are mixed with the fresh air-fuel mixture entering the combustion chamber. This cooling process is vital as it reduces the peak combustion temperature, which in turn decreases the formation of NOx.

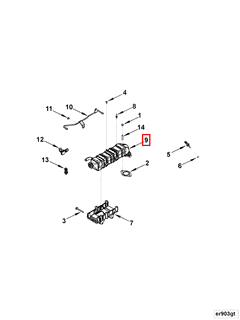

The EGR Cooler works in conjunction with several other components to ensure efficient operation of the EGR system. These components include the EGR valve, which controls the flow of exhaust gases, and the EGR pipe, which transports the gases from the exhaust manifold to the intake manifold. The cooler is often part of an EGR Cooler Kit, which may include additional components such as gaskets, clamps, and mounting brackets to facilitate installation and ensure a secure fit.

In summary, the EGR Cooler plays a significant role in enhancing the performance and environmental compliance of engine systems by effectively managing the temperature of recirculated exhaust gases, thereby contributing to reduced emissions and improved engine efficiency 4.

Conclusion

The 4937100 Exhaust Gas Recirculation Cooler by Cummins is a vital component in the EGR system, designed to reduce emissions and improve engine efficiency. Its robust design, compatibility with various Cummins engines, and significant role in lowering NOx emissions make it an essential part for modern commercial trucks. Proper installation, maintenance, and understanding of its function are crucial for optimal performance and compliance with environmental regulations.

-

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ ↩ -

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ ↩ ↩ -

Huzij, Robert, Spano, Angelo, and Bennett, Sean. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩ ↩ ↩ ↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.