This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

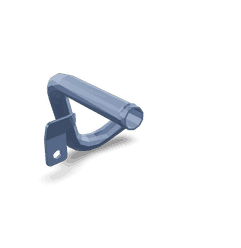

The Exhaust Cooler Water Inlet Tube, identified by part number 4937238, is a component manufactured by Cummins, a leading provider of diesel engines and related technologies. This tube is integral to the exhaust cooling system in heavy-duty truck engines, contributing to efficient engine operation and emissions control.

Function and Operation

The Exhaust Cooler Water Inlet Tube operates within the exhaust cooling system by directing coolant into the exhaust gas recirculation (EGR) cooler. Its role involves managing exhaust gas temperatures, which helps in reducing thermal stress on engine components and enhancing overall engine efficiency. By cooling the exhaust gases before they re-enter the engine, the tube aids in maintaining optimal operating temperatures and improving the combustion process 1.

Purpose of the Exhaust Cooler Water Inlet Tube

In the operation of a truck, this Cummins part plays a specific role by facilitating the cooling of exhaust gases. This cooling process is vital for emissions control, as it helps in reducing nitrogen oxides (NOx) and other harmful emissions. Additionally, it contributes to engine performance by ensuring that the recirculated exhaust gases are at a temperature that does not adversely affect combustion efficiency 2.

Key Features

The Exhaust Cooler Water Inlet Tube is designed with several key features that enhance its functionality. It is constructed from durable materials to withstand the high temperatures and pressures within the exhaust system. The tube’s design ensures efficient coolant flow, which is crucial for effective cooling. Additionally, it may include features such as reinforced connections to prevent leaks and ensure a secure fit within the exhaust system 3.

Benefits

The advantages provided by the Exhaust Cooler Water Inlet Tube include improved engine durability, as it helps in managing thermal loads on engine components. It also contributes to reduced emissions by aiding in the effective cooling of exhaust gases, which is essential for compliance with emissions regulations. Furthermore, the tube enhances fuel efficiency by supporting optimal engine operating conditions 4.

Installation and Integration

Installing this part in a truck’s exhaust system involves several steps and considerations. It is important to ensure that the tube is compatible with the specific engine model and exhaust system configuration. Installation typically requires disconnecting the existing inlet tube, if present, and securing the new tube in place with appropriate fittings. It is also crucial to check for any leaks post-installation to ensure a secure and efficient system.

Troubleshooting and Maintenance

Common issues associated with the Exhaust Cooler Water Inlet Tube may include leaks, blockages, or damage due to thermal stress. Diagnostic methods involve inspecting the tube for visible signs of wear or damage and checking the coolant flow for any irregularities. Maintenance practices include regular inspection of the tube and its connections, ensuring that there are no leaks or signs of corrosion. Additionally, it is important to monitor the overall performance of the exhaust cooling system to detect any issues early.

Performance Impact

The Exhaust Cooler Water Inlet Tube affects overall truck performance by contributing to fuel economy, emissions levels, and engine reliability. By ensuring that exhaust gases are cooled efficiently, the tube helps in maintaining optimal engine temperatures, which is beneficial for fuel efficiency. It also plays a role in reducing emissions, helping the vehicle meet regulatory standards. Furthermore, by managing thermal loads, the tube contributes to the longevity and reliability of the engine.

Environmental Considerations

The use of an Exhaust Cooler Water Inlet Tube offers environmental benefits by reducing pollutants emitted by the engine. Effective cooling of exhaust gases helps in lowering the levels of nitrogen oxides and other harmful emissions. This not only contributes to better air quality but also ensures compliance with stringent emissions regulations, reflecting Cummins’ commitment to environmental responsibility.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins is renowned for its innovation and commitment to quality in the automotive industry. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Cummins Engines

The Exhaust Cooler Water Inlet Tube, identified as part number 4937238, is a critical component in the cooling system of various Cummins engines. This part is designed to facilitate the flow of coolant into the exhaust cooler, ensuring efficient heat dissipation and maintaining optimal engine operating temperatures.

ISB (Chrysler)

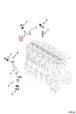

The ISB engine, developed by Chrysler, incorporates the Exhaust Cooler Water Inlet Tube (4937238) as part of its cooling system. This tube is integral to the exhaust cooler assembly, which helps manage the high temperatures generated by the engine’s exhaust gases. By directing coolant into the exhaust cooler, the inlet tube aids in reducing the temperature of the exhaust gases before they exit the engine, thereby enhancing the engine’s overall performance and longevity.

The integration of the Exhaust Cooler Water Inlet Tube in the ISB engine ensures that the cooling system operates effectively, contributing to the engine’s reliability and efficiency. This component is essential for maintaining the integrity of the exhaust cooler and ensuring that the engine operates within its specified temperature range.

Role in Engine Systems

The Exhaust Cooler Water Inlet Tube, identified by part number 4937238, is integral to the efficient operation of exhaust recirculation water plumbing systems. This component facilitates the controlled introduction of water into the exhaust cooler, ensuring optimal cooling performance.

Integration with Exhaust Recirculation Water Plumbing

In exhaust recirculation systems, the water inlet tube plays a significant role by directing water flow to the exhaust cooler. This process is essential for maintaining the temperature of recirculated exhaust gases within specified limits, enhancing engine efficiency and reducing emissions. The tube’s precise placement and secure connection to the plumbing system ensure consistent water delivery, which is vital for the cooler’s performance.

Function within the Water Inlet System

As part of the water inlet system, the Exhaust Cooler Water Inlet Tube is responsible for channeling water from the supply source to the exhaust cooler. This function is pivotal in dissipating heat from the exhaust gases, which is a key factor in the overall thermal management of the engine. The tube’s design allows for efficient water flow, minimizing the risk of blockages or leaks that could compromise system integrity.

Conclusion

In summary, the Exhaust Cooler Water Inlet Tube (part 4937238) is a fundamental component in the exhaust recirculation water plumbing and water inlet systems. Its role in facilitating water flow to the exhaust cooler is essential for maintaining engine performance and ensuring effective thermal management.

-

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.