This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

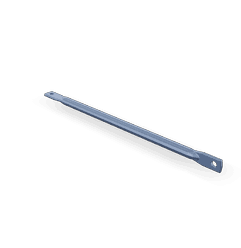

The Exhaust Outlet Connection Brace Assembly, identified by part number 4939443, is a component manufactured by Cummins. This assembly is integral to the operation of heavy-duty trucks, particularly in maintaining the structural integrity of the exhaust system and ensuring efficient exhaust flow. Cummins, a well-established name in the automotive industry, is recognized for its commitment to producing high-quality components designed to enhance the performance and reliability of commercial vehicles 1.

Function and Operation

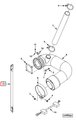

The Exhaust Outlet Connection Brace Assembly operates within the exhaust system of a truck by providing structural support to the exhaust outlet. It plays a role in maintaining the alignment and stability of the exhaust components, which is vital for the efficient flow of exhaust gases away from the engine. By securing the exhaust outlet, this assembly helps prevent vibrations and movement that could lead to leaks or damage within the exhaust system 2.

Purpose of the Exhaust Outlet Connection Brace Assembly

The primary role of the Exhaust Outlet Connection Brace Assembly in the overall operation of a truck is to contribute to effective exhaust management. It ensures that the exhaust system remains securely in place, which is important for maintaining engine performance. Proper exhaust flow is necessary for optimal engine operation, as it allows the engine to expel waste gases efficiently, thereby supporting combustion efficiency and reducing backpressure 3.

Key Features

The Exhaust Outlet Connection Brace Assembly is designed with several features that enhance its functionality. It is constructed from durable materials that can withstand the high temperatures and pressures present in the exhaust system. The design of the assembly includes precise fittings and connections that ensure a secure attachment to the exhaust components. Additionally, the assembly may incorporate features such as corrosion-resistant coatings to extend its service life in harsh operating environments.

Benefits

The advantages provided by the Exhaust Outlet Connection Brace Assembly include improved durability and enhanced exhaust efficiency. Its robust construction and secure fit help to maintain the integrity of the exhaust system, reducing the likelihood of leaks or failures. This contributes to overall vehicle performance by ensuring that the engine operates within optimal parameters, with efficient exhaust flow supporting combustion processes.

Installation Process

Installing the Exhaust Outlet Connection Brace Assembly requires careful attention to detail to ensure proper integration into the exhaust system. The process involves securing the assembly to the exhaust outlet and ensuring that all connections are tight and aligned correctly. It is important to follow manufacturer guidelines for torque specifications and alignment to achieve a secure and effective installation.

Common Issues and Troubleshooting

Typical problems associated with the Exhaust Outlet Connection Brace Assembly may include loosening of connections, corrosion, or damage from extreme temperatures. Troubleshooting these issues involves inspecting the assembly for signs of wear or damage, tightening any loose connections, and replacing any corroded or damaged components. Regular maintenance can help to identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure optimal performance and longevity of the Exhaust Outlet Connection Brace Assembly, regular inspection and maintenance are recommended. This includes checking for signs of corrosion, ensuring that all connections are secure, and verifying that the assembly is properly aligned within the exhaust system. Adhering to recommended maintenance intervals and performing inspections as part of routine vehicle servicing can help to maintain the efficiency and reliability of the exhaust system.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a history of producing high-quality components for commercial vehicles. The company is known for its commitment to innovation, quality, and customer satisfaction. Cummins components, including the Exhaust Outlet Connection Brace Assembly, are designed to meet the demanding requirements of heavy-duty truck operations, ensuring reliability and performance in a variety of operating environments.

Compatibility with Cummins Engines

The Exhaust Outlet Connection Brace Assembly, identified by part number 4939443, is a critical component in the exhaust system of various Cummins engines. This part is designed to provide structural support and stability to the exhaust outlet connection, ensuring the integrity and efficiency of the exhaust system.

QSC8.3 CM850 (CM2850)

The Exhaust Outlet Connection Brace Assembly is compatible with the QSC8.3 CM850 (CM2850) engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications such as construction equipment and industrial machinery. The brace assembly plays a vital role in maintaining the alignment and securing the exhaust outlet connection, which is crucial for the engine’s optimal operation and longevity.

Grouping of Engines

While the Exhaust Outlet Connection Brace Assembly is specifically designed for the QSC8.3 CM850 (CM2850) engine, it is also compatible with other Cummins engines that share similar exhaust system configurations. This includes various models within the Cummins QSC series, where the exhaust outlet connection design and structural requirements are analogous. Ensuring the correct fitment of this part is essential for maintaining the exhaust system’s integrity and performance across these engines.

Conclusion

The Exhaust Outlet Connection Brace Assembly (part 4939443) is an integral component in the assembly and structural integrity of the exhaust system within various engine configurations. This brace assembly is designed to connect and reinforce the exhaust outlet, ensuring a secure and stable connection between the exhaust manifold and the exhaust pipe.

In the context of engine systems, the brace assembly plays a significant role in maintaining the alignment and structural support of the exhaust components. It helps to absorb and distribute the vibrational forces generated by the engine, reducing the stress on the exhaust manifold and the exhaust pipe joints. This not only enhances the durability of the exhaust system but also contributes to the overall efficiency and performance of the engine by ensuring a consistent and unrestricted flow of exhaust gases.

Furthermore, the brace assembly aids in the thermal management of the exhaust system. By providing a robust connection, it helps to minimize heat transfer to adjacent engine components, thereby protecting sensitive parts from excessive heat exposure. This is particularly important in high-performance engines where thermal management is a key factor in maintaining optimal engine operation.

In summary, the Exhaust Outlet Connection Brace Assembly (part 4939443) is a vital component that ensures the structural integrity, alignment, and thermal management of the exhaust system, contributing to the reliable and efficient operation of the engine.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. Ed. (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.