4941455

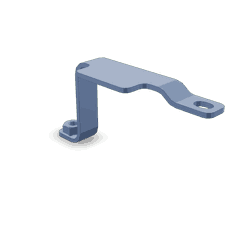

Exhaust Recirculation Cooler Bracket

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Recirculation Cooler Bracket, identified by part number 4941455, is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industry. This part plays a significant role in the exhaust recirculation system of heavy-duty trucks, contributing to the overall efficiency and environmental compliance of the vehicle.

Function and Operation

The Exhaust Recirculation Cooler Bracket operates within the exhaust recirculation system by supporting the cooler, a component instrumental in reducing nitrogen oxide (NOx) emissions. The bracket ensures the cooler is securely positioned, allowing it to effectively cool the recirculated exhaust gases before they are reintroduced into the engine’s intake. This process lowers the combustion temperature, thereby reducing NOx emissions, which are harmful pollutants 1.

Design and Construction

The design of the Exhaust Recirculation Cooler Bracket incorporates several key features to ensure durability and effectiveness. Constructed from high-strength materials, the bracket is engineered to withstand the high temperatures and pressures associated with exhaust systems. Its design includes precise mounting points and structural reinforcements to maintain the integrity of the cooler and ensure stable operation under varying driving conditions 2.

Integration Within the Exhaust System

Within the exhaust system of a heavy-duty truck, the Exhaust Recirculation Cooler Bracket plays a pivotal role by securely holding the cooler in place. It interacts closely with the exhaust recirculation valve and the cooler itself, facilitating the efficient flow of exhaust gases. This integration is crucial for the system’s performance, ensuring that the recirculated gases are adequately cooled before entering the engine, which contributes to both engine efficiency and emissions control 3.

Benefits of Using the Exhaust Recirculation Cooler Bracket

The use of the Exhaust Recirculation Cooler Bracket offers several advantages. It contributes to improved emissions control by ensuring the efficient operation of the cooler. This leads to enhanced engine performance, as the recirculated gases are optimally cooled, reducing the risk of engine knock and improving fuel efficiency. Additionally, the bracket aids in compliance with environmental regulations by helping to minimize NOx emissions, which is increasingly important in the automotive industry.

Maintenance and Troubleshooting

To ensure the optimal performance and longevity of the Exhaust Recirculation Cooler Bracket, regular maintenance is recommended. This includes inspecting the bracket for signs of wear or damage, ensuring that all mounting points are secure, and checking for any leaks in the exhaust system. Common issues may include corrosion or loosening of the bracket, which can affect the cooler’s performance. Troubleshooting tips include tightening any loose components and replacing damaged parts to maintain the system’s integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s commitment to advancing technology and sustainability is evident in its product offerings, including the Exhaust Recirculation Cooler Bracket, which exemplifies Cummins’ dedication to improving engine performance and reducing environmental impact.

Conclusion

The Exhaust Recirculation Cooler Bracket (Part 4941455) by Cummins is a critical component in the exhaust recirculation system of heavy-duty trucks. Its role in supporting the EGR cooler ensures efficient operation, contributing to reduced emissions and improved engine performance. Regular maintenance and understanding its function within the exhaust system are key to maximizing its benefits and ensuring compliance with environmental standards.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.