This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

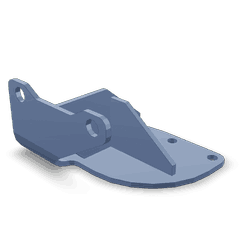

The Exhaust Outlet Connection Brace, identified by part number 4944219, is a component manufactured by Cummins, a prominent entity in the automotive industry. This brace is integral to the exhaust systems of heavy-duty trucks, enhancing engine efficiency and performance. Cummins’ commitment to quality and innovation ensures that this component meets the demanding requirements of heavy-duty applications.

Basic Concepts

Exhaust Outlet Connection Braces are engineered to secure the connection between the exhaust manifold and the exhaust pipe. This secure connection is crucial for the system’s integrity, ensuring efficient exhaust gas flow and minimizing backpressure. It also reduces the risk of leaks, which can decrease engine efficiency and increase emissions 1.

Purpose and Role

The Exhaust Outlet Connection Brace plays a pivotal role in the operation of a truck’s exhaust system. It provides a sturdy connection point, supporting the system’s structure and allowing for efficient exhaust gas flow. This efficient flow contributes to overall engine performance by reducing backpressure, which can otherwise impede engine operation. Additionally, the brace helps maintain the alignment of the exhaust components, ensuring the system operates within its designed parameters 2.

Key Features

The Exhaust Outlet Connection Brace by Cummins is engineered with several key features that enhance its performance and durability. It is constructed from high-strength materials to withstand the high temperatures and pressures of the exhaust system. The design ensures a secure fit with the exhaust manifold and pipe, and its construction includes features that facilitate easy installation and maintenance, contributing to its overall effectiveness in heavy-duty applications 3.

Benefits

Incorporating the Exhaust Outlet Connection Brace into a truck’s exhaust system offers several benefits. It contributes to improved exhaust flow, leading to enhanced engine efficiency. By maintaining a secure connection, it helps reduce emissions, as a well-sealed exhaust system is more effective at directing exhaust gases away from the engine compartment. Furthermore, the brace’s durable construction increases the longevity of the exhaust system, providing a reliable component that can withstand the rigors of heavy-duty use.

Installation and Compatibility

Proper installation of the Exhaust Outlet Connection Brace is crucial for its effective function. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and optimal performance. Compatibility with various truck models and engine types is an important consideration, ensuring that the brace fits correctly and functions as intended within the specific exhaust system it is designed for.

Troubleshooting and Maintenance

Regular maintenance and inspection of the Exhaust Outlet Connection Brace can help identify potential issues such as leaks or corrosion before they lead to more significant problems. Troubleshooting common issues may involve checking for signs of wear or damage, ensuring that all connections are secure, and addressing any corrosion that may affect the brace’s performance. Maintenance tips include keeping the area around the brace clean and free of debris, which can contribute to its longevity and optimal performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry. The company’s commitment to excellence is evident in its product offerings, which are designed to meet the demanding requirements of various applications, including heavy-duty trucks. Cummins’ focus on quality and innovation ensures that its components, like the Exhaust Outlet Connection Brace, are reliable and effective in enhancing vehicle performance.

Role of Part 4944219 Exhaust Outlet Connection Brace in Engine Systems

This Cummins part is an essential component that enhances the structural integrity and efficiency of the exhaust system in various engine setups. It plays a significant role in maintaining the alignment and stability of the exhaust outlet, ensuring that the exhaust gases are directed efficiently away from the engine.

When installing this part, it is integrated into the exhaust system to support the connection between the exhaust manifold and the exhaust pipe. This support is vital for withstanding the high temperatures and pressures generated during engine operation. The brace helps in reducing vibrations and potential stress on the exhaust components, which can lead to improved durability and performance of the exhaust system.

In the context of the exhaust outlet, the Exhaust Outlet Connection Brace ensures that the connection remains secure, minimizing the risk of leaks that could affect engine performance and emissions. It also aids in maintaining the proper spacing and orientation of the exhaust components, which is important for optimal airflow and reduced backpressure.

During package and product installation, the Exhaust Outlet Connection Brace is often included as part of a comprehensive exhaust system upgrade or repair kit. Its inclusion in the package signifies its importance in ensuring that the exhaust system is not only functional but also robust and reliable. Proper installation of the brace is key to achieving the desired outcomes in terms of engine efficiency and exhaust system longevity.

Conclusion

The Exhaust Outlet Connection Brace (Part #4944219) by Cummins is a critical component in the exhaust systems of heavy-duty trucks. Its role in maintaining a secure and stable connection between the exhaust manifold and pipe is vital for the system’s integrity and the engine’s overall performance. With its high-strength construction, easy installation features, and compatibility with various truck models, this part ensures durability, efficiency, and reliability in heavy-duty applications.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.