This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Gas Recirculation (EGR) Venturi, specifically Part #4966464 by Cummins, is a component designed to enhance the performance and efficiency of commercial truck engines. Cummins, a well-established manufacturer in the automotive and heavy-duty truck industry, produces this part to meet the stringent demands of modern diesel engines. This overview will delve into the functionality, design, and benefits of the EGR Venturi, providing a comprehensive understanding of its role in engine systems.

Basic Concepts of Exhaust Gas Recirculation Venturi

The EGR system is integral to the operation of diesel engines, aimed at reducing nitrogen oxides (NOx) emissions. It works by recirculating a portion of the exhaust gas back into the intake system, thereby lowering the combustion temperature and reducing NOx formation. The EGR Venturi is a key component within this system, facilitating the controlled flow of exhaust gases. It operates on the principle of fluid dynamics, where the venturi effect creates a pressure differential that draws exhaust gases into the intake stream. This technology is particularly beneficial in diesel engines, where higher combustion temperatures can lead to increased NOx emissions 1.

Purpose of the Exhaust Gas Recirculation Venturi

The 4966464 EGR Venturi plays a role in the operation of a truck engine by managing the flow of exhaust gases that are recirculated back into the intake system. This recirculation helps in reducing the overall emissions produced by the engine. By lowering the combustion temperature, the EGR Venturi contributes to a decrease in NOx emissions. Additionally, it aids in improving engine efficiency by ensuring a more consistent and controlled combustion process 2.

Key Features

The 4966464 EGR Venturi is engineered with precision to meet the demands of commercial truck engines. It is constructed from durable materials that can withstand the high temperatures and pressures within the engine system. The design incorporates specific engineering specifications to ensure optimal performance. Unique attributes of the venturi include its ability to maintain a consistent flow rate of exhaust gases, which is crucial for the effective operation of the EGR system.

Benefits

The advantages provided by the 4966464 EGR Venturi are significant. It contributes to emission reduction by effectively managing the recirculation of exhaust gases. This results in lower NOx emissions, which is beneficial for environmental compliance. Additionally, the venturi aids in improving fuel efficiency by promoting a more efficient combustion process. Compliance with environmental regulations is another key benefit, as the use of an EGR Venturi helps trucks meet the stringent emission standards set by regulatory bodies 3.

Installation and Integration

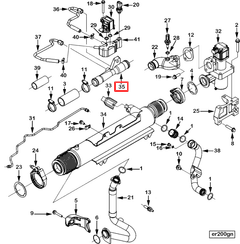

Proper installation of the 4966464 EGR Venturi within a truck’s EGR system is vital for its effective operation. Guidelines for installation should be followed to ensure compatibility with various engine models. The integration process involves connecting the venturi to the exhaust and intake systems, ensuring a secure and leak-free fit. This component is designed to be compatible with a range of Cummins engines, facilitating a straightforward integration process.

Troubleshooting and Maintenance

Common issues associated with the 4966464 EGR Venturi may include blockages or leaks within the system. Troubleshooting steps should involve checking for obstructions in the venturi and ensuring all connections are secure. Regular maintenance is recommended to ensure the longevity and optimal performance of the component. This includes periodic inspections and cleaning to prevent the buildup of deposits that could affect its operation.

Performance Impact

The 4966464 EGR Venturi affects engine performance in several ways. It contributes to a reduction in power output by lowering the combustion temperature, which can slightly decrease engine power. However, this is offset by the benefits of reduced emissions and improved fuel efficiency. The component plays a role in maintaining a balance between engine performance and environmental compliance.

Environmental and Regulatory Considerations

The environmental benefits of using an EGR Venturi are significant. By reducing NOx emissions, it helps in minimizing the environmental impact of diesel engines. This component is instrumental in helping trucks meet regulatory standards for emissions, ensuring compliance with environmental regulations. The use of EGR technology is a step towards more sustainable and eco-friendly transportation solutions 4.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, with a rich history of innovation and quality. The company offers a wide range of products designed to meet the diverse needs of the transportation sector. Cummins is committed to advancing technology and providing solutions that enhance engine performance, efficiency, and environmental compliance. Their product range includes a variety of components and systems that contribute to the overall performance and reliability of commercial vehicles.

Exhaust Gas Recirculation Venturi Compatibility

The Exhaust Gas Recirculation (EGR) Venturi part number 4966464, manufactured by Cummins, is a critical component in the EGR system of certain engines. This part is designed to integrate seamlessly with specific Cummins engine models, ensuring efficient EGR functionality.

ISM CM876 and QSM11 CM876 Engines

The EGR Venturi part 4966464 is compatible with the ISM CM876 and QSM11 CM876 engines. These engines benefit from the precise design of the EGR Venturi, which helps manage exhaust gas recirculation effectively. The part’s integration ensures that the EGR system operates smoothly, contributing to reduced emissions and improved engine performance.

Installation and Functionality

When installed in the ISM CM876 and QSM11 CM876 engines, the EGR Venturi part 4966464 plays a pivotal role in the EGR process. It is designed to draw exhaust gases from the engine’s exhaust manifold and recirculate them back into the intake manifold. This recirculation helps lower combustion temperatures, thereby reducing the formation of nitrogen oxides (NOx) and other pollutants.

Engine Performance and Emissions

The use of the EGR Venturi part 4966464 in these engines enhances overall engine performance by maintaining optimal combustion temperatures. This part ensures that the EGR system functions as intended, contributing to the engine’s efficiency and compliance with emission standards. The compatibility of this part with the ISM CM876 and QSM11 CM876 engines underscores its importance in maintaining the balance between performance and environmental responsibility.

Role of Part 4966464 Exhaust Gas Recirculation Venturi in Engine Systems

The Exhaust Gas Recirculation (EGR) Venturi, identified by part number 4966464, is an integral component in the EGR system of modern engine systems. Its primary function is to regulate the flow of exhaust gas that is recirculated back into the intake manifold.

When the EGR valve opens, the EGR Venturi controls the rate at which exhaust gases mix with the incoming air-fuel mixture. This mixture then enters the combustion chamber, where it helps to reduce the formation of nitrogen oxides (NOx) by lowering the combustion temperature.

The EGR Venturi works in conjunction with several other components to ensure efficient operation:

-

EGR Valve: This valve opens and closes to allow exhaust gases to flow into the intake manifold. The EGR Venturi helps to meter this flow accurately.

-

EGR Cooler: Often integrated into the system, the EGR cooler reduces the temperature of the recirculated exhaust gases before they enter the intake manifold. The Venturi ensures that the cooled gases are introduced at the correct rate.

-

Intake Manifold: The recirculated exhaust gases mix with the fresh air-fuel mixture in the intake manifold. The EGR Venturi ensures that this mixture is consistent and optimal for combustion.

-

Oxygen Sensor: Located in the exhaust stream, this sensor monitors the oxygen levels and provides feedback to the engine control unit (ECU). The EGR Venturi helps maintain the correct air-fuel ratio, which is crucial for accurate sensor readings.

-

Engine Control Unit (ECU): The ECU uses data from various sensors, including the oxygen sensor, to adjust the EGR valve and Venturi operation. This ensures that the EGR system operates within specified parameters for emissions control and engine performance.

In summary, the EGR Venturi (part 4966464) plays a significant role in the EGR system by precisely controlling the flow of recirculated exhaust gases. This not only helps in reducing emissions but also contributes to the overall efficiency and performance of the engine.

Conclusion

The Exhaust Gas Recirculation Venturi, part number 4966464 by Cummins, is a critical component in modern diesel engine systems. It plays a vital role in reducing emissions, improving fuel efficiency, and ensuring compliance with environmental regulations. The precise engineering and design of this part contribute to its effectiveness in managing exhaust gas recirculation, thereby enhancing engine performance and environmental sustainability.

-

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Modelling Diesel Combustion, P A Lakshminarayanan and Yogesh V Aghav, Springer Science, 2010

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011

↩ -

Fundamentals of Automotive Technology Principles and Practice, Kirk T Van Gelder, Jones Bartlett Learning, 2018

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.