This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

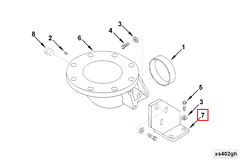

The Exhaust Outlet Connection Brace, identified by part number 4970928, is a component manufactured by Cummins, a well-established name in the automotive industry. This brace is integral to the exhaust system of heavy-duty trucks, contributing to the system’s overall efficiency and durability. Cummins ensures that this part meets the demanding requirements of heavy-duty applications.

Basic Concepts

The Exhaust Outlet Connection Brace is strategically positioned within the exhaust system, typically connecting the exhaust manifold to the turbocharger or the exhaust pipe. Its role involves securing and stabilizing the connection points, ensuring that the exhaust gases flow efficiently from the engine to the exhaust system. This Cummins part interacts closely with other components such as the exhaust manifold, turbocharger, and exhaust pipes, playing a role in maintaining the integrity of the exhaust system.

Purpose and Function

The primary role of the Exhaust Outlet Connection Brace is to provide structural support to the exhaust system. By securing the connection points, it helps maintain the alignment and integrity of the exhaust components, which is vital for efficient exhaust gas flow. This support contributes to the overall engine performance by ensuring that exhaust gases are expelled smoothly, which can influence engine backpressure and, consequently, engine efficiency 4.

Key Features

The Exhaust Outlet Connection Brace is designed with several key features that enhance its performance and durability. It is typically constructed from high-strength materials to withstand the high temperatures and pressures of the exhaust system. The design may include features such as heat shields or insulation to protect surrounding components from excessive heat. Additionally, the brace is engineered to be corrosion-resistant, ensuring longevity in various operating conditions 1.

Benefits

Incorporating the Exhaust Outlet Connection Brace into a truck’s exhaust system offers several advantages. It improves exhaust flow by maintaining the integrity of the exhaust path, which can contribute to better engine performance. The brace also helps reduce vibration within the exhaust system, leading to a more stable and quieter operation. Furthermore, its durable construction ensures long-term reliability, potentially contributing to fuel efficiency and emissions reduction by maintaining optimal exhaust system performance 2.

Installation and Compatibility

Proper installation of the Exhaust Outlet Connection Brace is crucial for its effective function. Installation procedures should follow manufacturer guidelines to ensure secure and correct placement. It is important to verify compatibility with the truck’s exhaust system to ensure that the brace fits properly and functions as intended. This may involve checking specifications or consulting with a professional to confirm that the brace is suitable for the specific application 3.

Maintenance and Troubleshooting

Routine maintenance of the Exhaust Outlet Connection Brace involves regular inspections for signs of wear, corrosion, or damage. It is important to check for any loose connections or compromised integrity, as these can affect the performance of the exhaust system. Troubleshooting common issues may involve tightening connections, replacing damaged components, or addressing any signs of heat damage. Regular inspections and timely replacements, when necessary, are key to maintaining the efficiency and safety of the exhaust system 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. The company’s product range extends beyond engines to include filtration, emissions, and powertrain-related components, all designed to meet the rigorous demands of various applications, particularly in the heavy-duty sector.

Exhaust Outlet Connection Brace in Cummins Engines

The Exhaust Outlet Connection Brace, part number 4970928, is a component in several Cummins engine models. This part is designed to provide structural support and stability to the exhaust system, ensuring that the exhaust outlet remains securely connected to the engine.

QSK19 and CM850 Engines

In the QSK19 and CM850 engines, the Exhaust Outlet Connection Brace plays a role in maintaining the integrity of the exhaust system. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The brace ensures that the exhaust outlet can withstand the stresses and vibrations inherent in these demanding environments.

MCRS Engines

The MCRS engines also benefit from the use of the Exhaust Outlet Connection Brace. These engines are typically employed in military and defense applications, where reliability and durability are paramount. The brace helps to secure the exhaust outlet, preventing any misalignment or detachment that could lead to performance issues or safety hazards.

Importance of the Exhaust Outlet Connection Brace

The Exhaust Outlet Connection Brace is important for maintaining the overall efficiency and safety of the engine. By providing a stable connection point, it helps to reduce the risk of exhaust leaks, which can not only degrade performance but also pose a significant safety risk due to the high temperatures and pressures involved.

Installation and Maintenance

Proper installation of the Exhaust Outlet Connection Brace is crucial to ensure that it functions effectively. Technicians should follow the manufacturer’s guidelines for torque specifications and alignment to avoid any issues during operation. Regular inspections and maintenance are also recommended to check for any signs of wear or damage, ensuring that the brace continues to perform its function reliably.

Integration with Key Components

-

Exhaust Manifold: The brace works in conjunction with the exhaust manifold to ensure that the manifold remains securely attached to the engine block. This connection is vital for the proper channeling of exhaust gases from the cylinders to the exhaust pipes.

-

Exhaust Pipes: By supporting the exhaust outlet, the brace helps in maintaining the correct positioning of the exhaust pipes. This is important for the smooth flow of exhaust gases and for minimizing the risk of leaks or disconnections.

-

Catalytic Converter: The structural support provided by the brace is also beneficial for the catalytic converter, which is positioned downstream of the exhaust manifold. A stable exhaust outlet ensures that the converter operates efficiently without being subjected to undue stress or movement.

-

Muffler and Tailpipe: Further down the exhaust system, the brace indirectly supports the muffler and tailpipe by ensuring that the entire system remains aligned. This alignment is key to reducing noise levels and enhancing the overall performance of the exhaust system.

Operational Benefits

The presence of the Exhaust Outlet Connection Brace enhances the operational efficiency of the engine system in several ways:

-

Reduced Vibration: By stabilizing the exhaust outlet, the brace helps in reducing vibrations that can be transmitted to other engine components. This leads to a smoother operation and potentially extends the lifespan of connected parts.

-

Improved Exhaust Flow: A stable and well-aligned exhaust system allows for better flow of exhaust gases, which can contribute to improved engine performance and fuel efficiency.

-

Enhanced Durability: The structural support provided by the brace contributes to the overall durability of the exhaust system, reducing the likelihood of premature wear or failure of components.

Conclusion

The Exhaust Outlet Connection Brace, part number 4970928, plays a supportive yet significant role in the engine system, ensuring that the exhaust components are securely and efficiently integrated. Its design and features contribute to the overall efficiency, durability, and safety of the exhaust system, making it a vital component in heavy-duty applications.

-

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.