This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

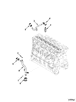

The Exhaust Cooler Water Outlet Tube, identified by part number 4980592, is a component manufactured by Cummins, a leading name in diesel engine technology. This tube is integral to the exhaust gas recirculation (EGR) cooling system in heavy-duty truck engines. Its role is to facilitate the efficient management of exhaust temperatures, thereby contributing to the overall engine efficiency and performance 1.

Function and Operation

The Exhaust Cooler Water Outlet Tube operates within the EGR cooling system by directing coolant flow from the exhaust cooler. This process helps in managing the temperature of the recirculated exhaust gases before they are reintroduced into the engine’s intake system. By maintaining optimal exhaust gas temperatures, the tube aids in enhancing engine efficiency and reducing emissions, which is a critical aspect of modern heavy-duty truck engine design 2.

Key Features

The design and construction of the Exhaust Cooler Water Outlet Tube are tailored for durability and efficiency. It is made from high-quality materials that can withstand the high temperatures and pressures typical in heavy-duty engine environments. The tube features secure connection types that ensure a reliable seal, preventing coolant leaks. Its design also includes features that enhance its resistance to corrosion and wear, ensuring long-term performance.

Benefits

The Exhaust Cooler Water Outlet Tube offers several advantages. It contributes to improved engine performance by ensuring that the EGR system operates within optimal temperature ranges. This results in more efficient combustion and reduced emissions. Additionally, the tube’s robust construction ensures durability under the high-stress conditions typical in heavy-duty trucking, leading to longer component life and reduced maintenance needs.

Installation and Compatibility

Proper installation of the Exhaust Cooler Water Outlet Tube is crucial for its effective operation. Installation procedures should follow manufacturer guidelines to ensure correct fitting and function. While specific compatibility details are provided separately, it is designed to integrate seamlessly with various Cummins engine models, enhancing its versatility across different applications.

Maintenance and Troubleshooting

Routine maintenance of the Exhaust Cooler Water Outlet Tube is recommended to ensure its longevity and efficiency. This includes regular inspections for signs of wear or corrosion and ensuring that all connections are secure. Common issues may include leaks or blockages, which can often be addressed through cleaning or replacement of affected parts.

Safety Considerations

When working with the Exhaust Cooler Water Outlet Tube, it is important to observe safety precautions. This includes allowing the engine to cool before performing any maintenance to avoid burns from hot components. Additionally, ensuring that the cooling system is properly pressurized before operation is critical to prevent coolant leaks and system failure.

Environmental Impact

The Exhaust Cooler Water Outlet Tube plays a role in reducing the environmental footprint of heavy-duty trucks. By contributing to more efficient engine operation and lower emissions, it supports efforts to minimize the impact of transportation on the environment. Its role in the EGR system is particularly significant in this regard, as it helps in meeting stringent emission standards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a full line of power generation and related technologies. With a history of innovation and a commitment to sustainability, Cummins has established itself as a trusted provider of diesel engines and engine-related components. The company’s focus on advancing technology and reducing environmental impact is evident in its product offerings, including the Exhaust Cooler Water Outlet Tube.

Compatibility with Cummins Engines

The Exhaust Cooler Water Outlet Tube, identified by part number 4980592, is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the flow of coolant from the exhaust cooler to the engine’s water jacket, ensuring efficient heat dissipation and maintaining optimal engine operating temperatures.

ISB (Chrysler)

The ISB engine, developed by Chrysler and powered by Cummins, is a robust and reliable engine series widely used in various heavy-duty applications. The Exhaust Cooler Water Outlet Tube is specifically engineered to fit seamlessly with the ISB engine, ensuring compatibility with its unique design and cooling requirements. This part is essential for maintaining the integrity of the exhaust cooler system and preventing overheating, which can lead to engine damage and reduced performance.

Compatibility Considerations

When integrating the Exhaust Cooler Water Outlet Tube into the ISB engine, it is crucial to ensure that the part is correctly aligned and securely fastened. Proper installation is vital for maintaining the efficiency of the cooling system and preventing leaks or failures. Technicians should refer to the engine’s service manual for detailed installation instructions and specifications to ensure a proper fit and function.

The Exhaust Cooler Water Outlet Tube is a key component in the cooling system of the ISB engine, and its compatibility with this engine series underscores the importance of using genuine Cummins parts for maintenance and repairs. Ensuring that this part is correctly installed and maintained is essential for the longevity and performance of the engine.

Role in Engine Systems

The Exhaust Cooler Water Outlet Tube, identified by part number 4980592, is an integral component in the efficient operation of engine systems that incorporate exhaust gas recirculation (EGR) and water cooling mechanisms. This tube facilitates the flow of water from the exhaust cooler, ensuring that the cooling process is effective and that the engine maintains optimal operating temperatures.

In the context of the EGR system, the Exhaust Cooler Water Outlet Tube works in conjunction with the exhaust recirculation water system. As exhaust gases are recirculated back into the engine to reduce nitrogen oxides (NOx) emissions, they pass through the exhaust cooler where they are cooled by water. The tube then directs the cooled water away from the cooler, allowing it to be reused or expelled from the system as necessary.

The integration of this tube within the plumbing of the engine’s cooling system is designed to enhance the overall efficiency of the cooling process. By providing a dedicated pathway for the outlet water, the tube helps to maintain a consistent flow, which is essential for the stable operation of the engine. This consistent flow is particularly important in high-performance or high-stress engine environments where temperature management is key to longevity and performance.

Furthermore, the Exhaust Cooler Water Outlet Tube is engineered to withstand the pressures and temperatures associated with engine cooling systems. Its placement and design ensure that it contributes to the reduction of thermal stress on engine components, thereby supporting the durability and reliability of the engine system as a whole.

Conclusion

In summary, the Exhaust Cooler Water Outlet Tube (part 4980592) plays a significant role in the engine’s cooling and emission control systems by ensuring efficient water flow from the exhaust cooler, contributing to the engine’s thermal management, and supporting the overall performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.