This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Transfer Tube 4992196, a component designed by Cummins for commercial truck exhaust systems, facilitates the efficient transfer of exhaust gases from the engine to the exhaust system. This part is integral to maintaining the overall performance and efficiency of the vehicle.

Basic Concepts of Exhaust Transfer Tubes

An Exhaust Transfer Tube serves as a conduit within the exhaust system, allowing for the smooth passage of exhaust gases. It directs these gases away from the engine, contributing to the reduction of backpressure and enhancing the engine’s ability to expel exhaust efficiently. This can lead to improved engine performance and fuel efficiency 1.

Purpose of the Exhaust Transfer Tube 4992196

The Exhaust Transfer Tube 4992196 is engineered to optimize the flow of exhaust gases in commercial trucks. By ensuring a direct and unobstructed path for these gases, it helps in reducing backpressure within the engine. This reduction in backpressure can lead to enhanced engine performance and potentially contribute to better fuel economy. Additionally, it plays a part in the truck’s emissions control system by ensuring that exhaust gases are efficiently managed and directed to subsequent treatment stages 2.

Key Features

This Cummins part is constructed from durable materials designed to withstand the high temperatures and pressures of the exhaust system. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Unique characteristics of this tube may include reinforced sections to handle high stress areas and a smooth interior to minimize resistance to exhaust flow.

Benefits

The installation of the Exhaust Transfer Tube 4992196 offers several benefits. It contributes to improved exhaust efficiency by ensuring a direct and unobstructed path for exhaust gases. This can lead to reduced backpressure within the engine, potentially enhancing engine performance. Additionally, by optimizing exhaust flow, it may contribute to better fuel economy. The design and construction of this tube also support its durability and reliability under the demanding conditions of commercial truck operation 3.

Installation and Integration

Proper installation of the Exhaust Transfer Tube 4992196 is crucial for its effective function within the exhaust system. The process involves securing the tube in place using appropriate tools and ensuring all connections are tight and leak-free. Careful attention to the manufacturer’s guidelines during installation will help ensure the tube operates as intended, contributing to the overall efficiency and performance of the truck.

Common Issues and Troubleshooting

Common issues with the Exhaust Transfer Tube 4992196 may include leaks, corrosion, or blockages. Regular inspections can help identify these problems early. Troubleshooting steps may involve checking connections for tightness, inspecting the tube for signs of wear or damage, and ensuring there are no obstructions within the tube. Addressing these issues promptly can help maintain the efficiency and performance of the exhaust system.

Maintenance Tips

To ensure the longevity and optimal performance of the Exhaust Transfer Tube 4992196, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the tube as necessary and replacing it according to the manufacturer’s guidelines can help prevent issues and ensure the exhaust system operates efficiently. Adhering to these maintenance practices can contribute to the overall reliability and performance of the truck.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a strong reputation within the commercial truck industry, Cummins is known for its high-quality products that enhance the performance, efficiency, and reliability of vehicles. The Exhaust Transfer Tube 4992196 is a testament to Cummins’ commitment to providing durable and efficient components for the commercial trucking sector.

Cummins Exhaust Transfer Tube 4992196 Compatibility

The Cummins Exhaust Transfer Tube part number 4992196 is designed to fit seamlessly with several models of Cummins engines, ensuring efficient exhaust gas transfer and optimal engine performance. This part is engineered to meet the specific requirements of the following engine models:

- QSB5.9 CM850

This exhaust transfer tube is integral to the engine’s exhaust system, facilitating the movement of exhaust gases from the turbocharger to the exhaust manifold. Its precision engineering ensures a secure fit and reliable operation, contributing to the overall efficiency and longevity of the engine.

For the QSB5.9 CM850 engine, the exhaust transfer tube is a critical component that interfaces directly with the turbocharger and exhaust manifold. Its design allows for effective heat management and minimizes exhaust gas back pressure, enhancing engine performance and fuel efficiency.

When installing the Cummins Exhaust Transfer Tube 4992196, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. This part is specifically crafted to work with the QSB5.9 CM850 engine, ensuring compatibility and reliability in various operational conditions.

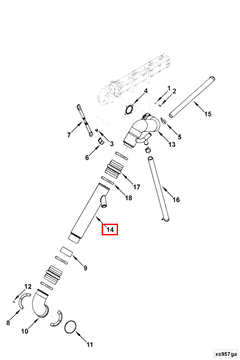

Role of Part 4992196 Exhaust Transfer Tube in Engine Systems

The Exhaust Transfer Tube, identified by part number 4992196, is a component in the efficient operation of engine systems. This component is strategically positioned to facilitate the smooth transfer of exhaust gases from the engine’s exhaust manifold to the exhaust outlet.

Connection to Exhaust Manifold

The Exhaust Transfer Tube connects directly to the exhaust manifold, which is responsible for collecting exhaust gases from the engine’s cylinders. This connection ensures that the gases are channeled effectively, minimizing any potential backpressure that could impede engine performance. The tube’s design allows for a secure and leak-free attachment, which is vital for maintaining the integrity of the exhaust system.

Pathway to Exhaust Outlet

Once connected to the exhaust manifold, the Exhaust Transfer Tube serves as a conduit for the exhaust gases, directing them towards the exhaust outlet. This pathway is designed to be as direct and unobstructed as possible to enhance the flow of gases. The tube’s material and construction are chosen to withstand the high temperatures and pressures associated with exhaust gases, ensuring durability and reliability.

Integration with Exhaust System Components

In addition to its primary role, the Exhaust Transfer Tube also integrates seamlessly with other components of the exhaust system. It may connect to catalytic converters, mufflers, or other emission control devices, depending on the specific engine configuration. This integration is designed to optimize the performance of these components, ensuring that they function efficiently within the overall exhaust system.

Enhancing Engine Efficiency

By providing a reliable and efficient pathway for exhaust gases, the Exhaust Transfer Tube contributes to the overall efficiency of the engine. It helps in reducing emissions by ensuring that gases are properly directed through the exhaust system, where they can be treated and released in a controlled manner. This not only enhances engine performance but also complies with environmental regulations.

Conclusion

In summary, the Exhaust Transfer Tube (part 4992196) plays a significant role in the exhaust system by ensuring the efficient transfer of gases from the exhaust manifold to the exhaust outlet, thereby supporting the engine’s performance and emission control objectives.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.