This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Connection Bracket 5257923 is a component designed for use in the exhaust systems of commercial trucks. Its primary role is to secure and align various exhaust components, ensuring they function cohesively within the system. This Cummins part is integral to maintaining the structural integrity and operational efficiency of the truck’s exhaust system.

Purpose and Function

The Exhaust Connection Bracket plays a role in the exhaust system by securing and aligning exhaust components. It ensures that these components remain in the correct position, which is vital for the efficient flow of exhaust gases. Proper alignment and secure mounting contribute to the overall performance and longevity of the exhaust system, reducing the likelihood of leaks and enhancing the system’s durability 1.

Key Features

The design of the Exhaust Connection Bracket incorporates robust materials and engineering to withstand the harsh conditions of commercial truck operations. It is constructed from high-strength materials that offer resistance to corrosion and mechanical stress. The bracket’s design includes features that facilitate easy installation and alignment, ensuring that it can be securely fastened to the truck’s chassis and exhaust components 2.

Benefits

Utilizing the Exhaust Connection Bracket offers several advantages. It enhances the integrity of the exhaust system by providing a stable connection point for exhaust components. This stability reduces vibrations that can lead to wear and tear on the exhaust system. Additionally, the bracket contributes to the longevity of exhaust components by minimizing stress and movement, which can cause premature failure 3.

Installation Process

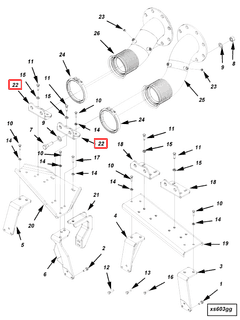

Installing the Exhaust Connection Bracket requires careful attention to alignment and securing methods. The process involves positioning the bracket in the designated location on the truck’s chassis, ensuring it is level and aligned with the exhaust components. Once positioned, the bracket should be secured using the appropriate fasteners, following the manufacturer’s guidelines for torque specifications to ensure a secure fit without over-tightening.

Troubleshooting Common Issues

Common issues with Exhaust Connection Brackets may include misalignment, corrosion, or damage from road debris. Troubleshooting these issues involves inspecting the bracket for signs of wear or damage, ensuring it is properly aligned with the exhaust components, and checking for secure fastening. If corrosion is present, cleaning and reapplying a protective coating may be necessary. In cases of significant damage, replacement of the bracket may be required.

Maintenance Tips

Regular maintenance of the Exhaust Connection Bracket is important for prolonging its life and ensuring the continued efficiency of the exhaust system. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the bracket and reapplying a protective coating can help prevent corrosion. Additionally, ensuring that all fasteners are tight and that the bracket remains properly aligned with the exhaust components will contribute to its longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines and components for on-highway, off-highway, and stationary applications, serving a wide array of industries. Cummins’ reputation in the commercial truck industry is built on its dedication to producing reliable, high-performance components that meet the demanding requirements of commercial vehicle operations.

Exhaust Connection Bracket for Cummins Engines

The Exhaust Connection Bracket, part number 5257923, is a component in the exhaust system of various Cummins engines. This bracket is designed to securely attach the exhaust manifold to the engine block, ensuring a stable and leak-free connection.

K38 Engines

For the K38 engine series, the Exhaust Connection Bracket plays a role in maintaining the integrity of the exhaust system. It is engineered to withstand the high temperatures and pressures typical of diesel engines, providing a robust mounting point for the exhaust manifold. This bracket ensures that the exhaust gases are efficiently directed away from the engine, contributing to the overall performance and longevity of the engine.

K50 Engines

Similarly, in the K50 engine series, the Exhaust Connection Bracket is integral to the exhaust system’s functionality. This bracket is specifically designed to fit the unique configuration of the K50 engine, ensuring a precise and secure attachment of the exhaust manifold. Its design allows for minimal vibration and stress on the exhaust components, which is crucial for maintaining the engine’s efficiency and reliability.

Compatibility and Installation

The Exhaust Connection Bracket is compatible with both the K38 and K50 engines, making it a versatile component for Cummins engine users. Proper installation of this bracket is essential to ensure that the exhaust system operates efficiently and safely. Technicians should follow the manufacturer’s guidelines for torque specifications and alignment to prevent any issues during operation.

By providing a stable and secure connection for the exhaust manifold, the Exhaust Connection Bracket helps maintain the performance and durability of Cummins engines, ensuring that they run smoothly and efficiently.

Role of Part 5257923 Exhaust Connection Bracket in Engine Systems

The Exhaust Connection Bracket, identified by part number 5257923, serves as a component in the assembly and functionality of engine systems. Its primary role is to securely connect the exhaust outlet to the exhaust system, ensuring a stable and efficient flow of exhaust gases away from the engine.

When integrating the Exhaust Connection Bracket into an engine system, it is positioned between the exhaust outlet and the subsequent exhaust components. This bracket not only provides a robust mounting point but also helps in maintaining the alignment of the exhaust system. Proper alignment is essential for minimizing vibrations and ensuring that the exhaust gases are directed correctly through the system.

In addition to its structural role, the Exhaust Connection Bracket also plays a part in managing thermal expansion. As the engine operates, components expand due to heat. The bracket’s design allows for some degree of movement, accommodating this expansion without compromising the integrity of the exhaust connection. This feature is particularly important in high-performance engines where thermal management is a key consideration.

Furthermore, the Exhaust Connection Bracket contributes to the overall reduction of noise and emissions. By ensuring a tight and secure connection, it helps prevent leaks that could lead to increased noise levels and the release of unburned hydrocarbons into the atmosphere. This is especially relevant in modern engine systems where stringent emission regulations are in place.

Conclusion

The Exhaust Connection Bracket 5257923 is an integral component that enhances the reliability, efficiency, and performance of engine systems by providing a secure, aligned, and thermally managed connection between the exhaust outlet and the exhaust system. Its robust design and compatibility with various Cummins engines make it a critical part for maintaining the structural integrity and operational efficiency of the exhaust system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.