This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

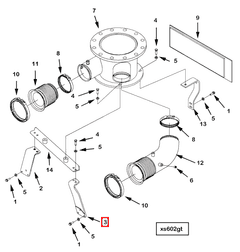

The Exhaust Collector Connection Bracket, identified by Part #5257988, is a component manufactured by Cummins, a renowned leader in the production of diesel engines and related technologies. This bracket plays a significant role in the exhaust systems of heavy-duty trucks, facilitating the efficient transfer of exhaust gases from the engine to the exhaust system 1.

Basic Concepts

The Exhaust Collector Connection Bracket serves as an interface within the exhaust system. It connects the exhaust manifold to the exhaust pipe, ensuring a secure and efficient pathway for exhaust gases to exit the engine. This bracket is designed to withstand high temperatures and pressures, maintaining the integrity of the exhaust flow. It interfaces with other components such as the exhaust manifold, exhaust pipe, and potentially catalytic converters or turbochargers, depending on the engine configuration 2.

Purpose and Role

The primary purpose of the Exhaust Collector Connection Bracket is to facilitate the smooth and efficient flow of exhaust gases from the engine’s cylinders to the exhaust system. By providing a stable and secure connection, it helps to minimize leaks and ensure that exhaust gases are directed away from the engine compartment effectively. This contributes to overall engine performance by reducing backpressure and enhancing the efficiency of the exhaust system 3.

Key Features

The Exhaust Collector Connection Bracket is constructed from high-quality materials, typically heat-resistant alloys, to endure the extreme conditions within the exhaust system. Its design includes features such as precision-machined mounting points and robust flanges to ensure a secure fit. Additionally, the bracket may incorporate gaskets or seals to prevent leaks, enhancing its functionality and reliability 4.

Benefits

The use of the Exhaust Collector Connection Bracket offers several advantages. It improves exhaust efficiency by ensuring a tight and leak-free connection, which helps to maintain optimal engine performance. Additionally, by facilitating efficient exhaust flow, it contributes to reduced emissions, aligning with environmental regulations. The durable construction of the bracket ensures long-term reliability and resistance to the harsh conditions within the exhaust system 5.

Installation Process

Installing the Exhaust Collector Connection Bracket requires careful attention to detail. Begin by ensuring the engine is cool and the exhaust system is free of debris. Align the bracket with the exhaust manifold and exhaust pipe, ensuring all mounting points are correctly positioned. Secure the bracket using the appropriate fasteners, torqued to the manufacturer’s specifications to ensure a tight and secure fit. Finally, inspect the connection for any signs of leaks or misalignment 6.

Common Issues and Troubleshooting

Typical issues with the Exhaust Collector Connection Bracket may include leaks due to gasket failure, corrosion, or improper installation. To address these issues, inspect the bracket and gaskets for signs of wear or damage. Replace any compromised components and ensure all fasteners are tightened to the correct specifications. Regular inspection and maintenance can help prevent these issues from arising 7.

Maintenance Tips

To ensure the optimal performance and longevity of the Exhaust Collector Connection Bracket, routine maintenance is recommended. Inspect the bracket and gaskets during regular engine service intervals for signs of wear, corrosion, or leaks. Clean the bracket and surrounding areas to remove any buildup of soot or debris. Replace gaskets or seals as needed to maintain a secure and leak-free connection 8.

Cummins Overview

Cummins is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a strong reputation for quality and innovation, Cummins has been a trusted name in the automotive and heavy-duty truck industries for decades. Their commitment to manufacturing high-quality components ensures that their products, like the Exhaust Collector Connection Bracket, meet the demanding requirements of modern engines 9.

Cummins Exhaust Collector Connection Bracket 5257988

The Cummins Exhaust Collector Connection Bracket part number 5257988 is a critical component in the exhaust system of certain Cummins engines. This bracket plays a pivotal role in maintaining the structural integrity and alignment of the exhaust collector, ensuring optimal performance and longevity of the engine 10.

K38 Engines

The Exhaust Collector Connection Bracket 5257988 is specifically designed to fit the K38 series engines. These engines are known for their robust design and are often used in heavy-duty applications, such as construction equipment and industrial machinery. The bracket’s precise fit and robust construction are essential for withstanding the high temperatures and pressures encountered in these demanding environments 11.

Grouping of Engines

In addition to the K38 series, the Exhaust Collector Connection Bracket 5257988 is also compatible with other Cummins engines that share similar design and operational characteristics. These engines typically include those in the following categories:

- Industrial Engines: Designed for use in industrial settings where reliability and durability are paramount.

- Construction Equipment: Built to handle the rigorous demands of construction sites, including heavy loads and harsh operating conditions.

- Marine Engines: Engineered to perform in marine environments, where they must resist corrosion and maintain performance in salty, humid conditions.

The bracket’s design ensures it can be securely fastened to the exhaust collector, providing a stable connection that minimizes vibration and stress on the exhaust system. This stability is crucial for preventing leaks and maintaining the efficiency of the exhaust system, which in turn helps to reduce emissions and improve overall engine performance 12.

Conclusion

The Exhaust Collector Connection Bracket, identified by part number 5257988, serves as a pivotal interface within the engine’s exhaust system. This bracket is designed to securely connect the exhaust collector to the exhaust outlet, ensuring a stable and efficient transfer of exhaust gases from the engine cylinders to the exhaust system. The connection facilitated by this Cummins part is essential for maintaining the structural integrity of the exhaust system. It allows for the proper alignment of the exhaust collector with the exhaust outlet, which is vital for the effective channeling of exhaust gases away from the engine. This alignment is key to minimizing backpressure, which can adversely affect engine performance if not managed correctly. Furthermore, the bracket plays a role in absorbing and dissipating vibrations that occur during engine operation. By providing a robust connection point, it helps in reducing the stress on both the exhaust collector and the exhaust outlet, contributing to the longevity and reliability of the exhaust system components. In summary, the Exhaust Collector Connection Bracket is an integral component that ensures the seamless integration of the exhaust collector with the exhaust outlet, supporting the overall efficiency and durability of the engine’s exhaust system 13.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659621.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659621.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659621.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659621.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659621.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659621.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.