This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

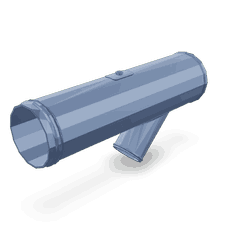

The Wiring Harness Exhaust Transfer Tube, identified by Part #5262764, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This part is integral to the operation of commercial trucks, facilitating both exhaust management and electrical connectivity. Cummins, known for its robust and reliable engine solutions, provides this component as part of its comprehensive range of truck parts 1.

Basic Concepts

To understand the Wiring Harness Exhaust Transfer Tube, it is important to grasp the concepts of wiring harnesses and exhaust transfer tubes. A wiring harness is a bundled assembly of electrical cables and wires that transmit signals and power within a vehicle. It is designed to organize and protect the wires, ensuring efficient and reliable electrical connections 2. An exhaust transfer tube, on the other hand, is a component that directs exhaust gases from one part of the exhaust system to another, playing a role in managing the flow of these gases. When integrated, these components work together to ensure that the truck’s exhaust system operates efficiently while maintaining the integrity of its electrical systems.

Purpose and Function

The Wiring Harness Exhaust Transfer Tube serves a dual purpose in the operation of a truck. It plays a role in the exhaust system by directing the flow of exhaust gases, which helps in managing emissions and maintaining engine performance. Additionally, it integrates with the truck’s electrical system, providing a secure pathway for wiring that is exposed to the high temperatures and vibrations typical of an exhaust environment. This integration ensures that the electrical connections remain reliable and functional under demanding conditions.

Key Features

The Wiring Harness Exhaust Transfer Tube is designed with several key features that enhance its performance and durability. It is constructed from high-temperature resistant materials, ensuring it can withstand the harsh conditions of the exhaust system. The design includes protective shielding for the wiring, which guards against heat and physical damage. Additionally, the tube is engineered to fit precisely within the truck’s exhaust system, ensuring a secure and efficient connection. Technological integrations such as heat-resistant coatings and vibration dampening elements further contribute to its reliability and longevity.

Benefits

The integration of the Wiring Harness Exhaust Transfer Tube into a truck’s system offers several advantages. It contributes to improved exhaust flow, which can enhance engine performance and efficiency. The secure routing of electrical wires through the tube ensures enhanced electrical reliability, reducing the risk of connectivity issues that can arise from exposed wiring. Additionally, by maintaining efficient exhaust management and reliable electrical connections, the tube can potentially contribute to increases in overall engine efficiency.

Installation Process

Installing the Wiring Harness Exhaust Transfer Tube requires careful attention to detail to ensure proper function and safety. The process involves disconnecting the battery to prevent electrical shocks, removing the old tube if present, and carefully routing the new tube through the exhaust system. It is important to secure all connections tightly to prevent leaks and ensure that the wiring is properly shielded. Following the manufacturer’s instructions and using the appropriate tools will help in achieving a successful installation. Common pitfalls to avoid include improper sealing, which can lead to exhaust leaks, and insufficient shielding of the wiring, which can result in electrical issues.

Maintenance and Troubleshooting

Regular maintenance of the Wiring Harness Exhaust Transfer Tube is important to ensure its continued reliable operation. This includes periodic inspections for signs of wear, corrosion, or damage to both the tube and the wiring. Cleaning the tube to remove any buildup of exhaust residue can also help maintain its efficiency. Troubleshooting common issues may involve checking for loose connections, inspecting the wiring for signs of damage, and ensuring that the tube is properly sealed within the exhaust system. Addressing these issues promptly can help prevent more significant problems down the line.

Compatibility and Applications

The Wiring Harness Exhaust Transfer Tube is designed for use in specific types of trucks and engine models. It is important to consult the manufacturer’s guidelines to ensure compatibility with your vehicle. Notable applications may include use in heavy-duty trucks where reliable exhaust management and electrical connectivity are critical for performance and safety.

Safety Considerations

When working with the Wiring Harness Exhaust Transfer Tube, it is important to observe safety protocols. This includes wearing appropriate personal protective equipment, ensuring that the vehicle’s battery is disconnected before beginning work to prevent electrical shocks, and allowing the exhaust system to cool before making any adjustments or inspections. Handling exhaust components requires caution due to the high temperatures they can reach, and working with electrical systems necessitates careful attention to prevent short circuits or other hazards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 3.

Cummins Engine Wiring Harness Exhaust Transfer Tube Compatibility

The Cummins part number 5262764, which is a Wiring Harness Exhaust Transfer Tube, is designed to fit seamlessly with several Cummins engine models. This part is integral to ensuring the proper electrical connectivity and functionality of the engine’s exhaust system.

QSB5.9 CM850

The QSB5.9 CM850 engine is one of the models that benefit from the 5262764 Wiring Harness Exhaust Transfer Tube. This engine is known for its robust performance and reliability, making it a popular choice for various applications. The wiring harness ensures that the electrical connections within the exhaust system are secure and efficient, contributing to the overall performance and longevity of the engine.

Grouping of Engines

While the QSB5.9 CM850 is a specific model, the 5262764 Wiring Harness Exhaust Transfer Tube is compatible with a range of Cummins engines. This compatibility extends to other models within the same series, ensuring that the part can be used across multiple engine types. The design of the harness is standardized to fit various engine configurations, making it a versatile component for Cummins engine maintenance and repair.

By ensuring that the Wiring Harness Exhaust Transfer Tube is correctly installed, engine operators can maintain optimal performance and reliability of their Cummins engines. This part plays a role in the electrical system of the exhaust, facilitating the transfer of necessary signals and power.

Role of Part 5262764 Wiring Harness Exhaust Transfer Tube in Engine Systems

The Part 5262764 Wiring Harness Exhaust Transfer Tube is an integral component in the orchestration of engine systems, specifically in the management and regulation of exhaust flow. This component is designed to facilitate a seamless connection between various exhaust system components, ensuring efficient operation and performance.

Connection to Exhaust Components

The primary function of the Wiring Harness Exhaust Transfer Tube is to establish a secure and reliable connection between the exhaust manifold and the exhaust outlet. This connection is vital for the uninterrupted flow of exhaust gases from the engine to the exhaust system. The tube’s design allows for flexibility and durability, accommodating the thermal expansion and contraction that occur during engine operation.

Integration with Exhaust Outlet

At the exhaust outlet, the Wiring Harness Exhaust Transfer Tube plays a significant role in maintaining the integrity of the exhaust system. It ensures that the exhaust gases are directed efficiently away from the engine, reducing backpressure and enhancing engine performance. The tube’s construction is tailored to withstand high temperatures and corrosive exhaust gases, contributing to the longevity and reliability of the exhaust system.

Enhancing System Efficiency

By providing a robust and efficient connection, the Wiring Harness Exhaust Transfer Tube contributes to the overall efficiency of the engine system. It aids in reducing emissions by ensuring that exhaust gases are properly channeled and processed. Additionally, the tube’s design helps in minimizing noise and vibration, leading to a smoother and more comfortable driving experience.

Supporting Engine Performance

The efficient transfer of exhaust gases facilitated by the Wiring Harness Exhaust Transfer Tube is essential for optimal engine performance. It allows the engine to operate within its designed parameters, ensuring that power output and fuel efficiency are maintained at desired levels. The tube’s role in managing exhaust flow is a testament to the intricate balance required in engine systems for peak performance.

Conclusion

The Wiring Harness Exhaust Transfer Tube, part number 5262764, is a critical component in the efficient operation of Cummins engines. Its dual role in managing exhaust flow and ensuring reliable electrical connectivity makes it indispensable for maintaining engine performance and efficiency. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this component. Cummins’ commitment to quality and innovation ensures that this part meets the demanding requirements of commercial and industrial applications.

-

Boyce, M.P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.