This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Gas Recirculation Valve (Part #5271307) by Cummins is a component designed to manage the recirculation of exhaust gases back into the engine’s intake. This valve plays a role in reducing emissions and enhancing engine efficiency in commercial trucks. Its significance lies in its ability to help meet stringent emissions standards while maintaining or improving engine performance 1.

Basic Concepts of Exhaust Gas Recirculation Valves

Exhaust Gas Recirculation (EGR) Valves operate on the principle of recirculating a portion of an engine’s exhaust gas back to the engine cylinders. This process dilutes the oxygen in the intake air, which lowers the combustion temperature and reduces the formation of nitrogen oxides (NOx). By integrating EGR technology, engines can achieve a balance between power output and emissions control 2.

Role of the Exhaust Gas Recirculation Valve in Truck Operation

The Exhaust Gas Recirculation Valve contributes to the operation of commercial trucks by regulating the flow of exhaust gases that are recirculated into the engine. This regulation helps in controlling emissions, particularly NOx, and supports the engine’s efficiency. The valve’s operation is synchronized with the engine’s control system to optimize performance under varying load conditions 3.

Key Features of the Exhaust Gas Recirculation Valve

The Exhaust Gas Recirculation Valve is characterized by its robust construction and precision engineering. It is designed to withstand the harsh operating conditions typical of commercial truck engines. The valve’s compatibility with Cummins engines ensures seamless integration and reliable performance. Its design incorporates advanced materials and manufacturing techniques to enhance durability and efficiency.

Benefits of Using the Exhaust Gas Recirculation Valve

Utilizing the Exhaust Gas Recirculation Valve offers several advantages. It contributes to improved fuel efficiency by optimizing the combustion process. The valve also plays a role in reducing emissions, helping trucks comply with environmental regulations. Additionally, it supports enhanced engine performance by maintaining optimal operating conditions.

Troubleshooting and Maintenance Tips

To ensure the Exhaust Gas Recirculation Valve operates effectively, regular maintenance is recommended. This includes checking for carbon buildup, ensuring the valve moves freely, and verifying that the electrical connections are secure. Addressing these aspects can help prevent common issues such as reduced engine performance or increased emissions.

Integration with Cummins Engines

The Exhaust Gas Recirculation Valve is engineered to integrate seamlessly with Cummins engines. This integration enhances the engine’s efficiency and reliability by ensuring that the EGR system operates in harmony with the engine’s control strategies. The valve’s design and functionality are tailored to complement the performance characteristics of Cummins engines.

Environmental Impact

The use of Exhaust Gas Recirculation technology, as exemplified by the Exhaust Gas Recirculation Valve, contributes to reduced nitrogen oxide emissions. This reduction plays a role in minimizing the environmental impact of commercial trucks. By complying with emissions regulations, trucks equipped with this technology support efforts to improve air quality and reduce the carbon footprint of transportation.

Technological Advancements

The Exhaust Gas Recirculation Valve incorporates several technological advancements. These include precision machining for accurate valve operation and the use of advanced materials to enhance durability. Such innovations ensure the valve meets the demands of modern engine systems while contributing to overall engine efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation in diesel engine technology, Cummins is recognized for its commitment to quality, performance, and environmental stewardship. The company’s reputation is built on a foundation of engineering excellence and a dedication to meeting the evolving needs of its customers.

Exhaust Gas Recirculation Valve 5271307 Compatibility

The Exhaust Gas Recirculation (EGR) Valve part number 5271307 is designed to fit a range of Cummins engines, ensuring optimal performance and emissions control across various applications. This part is integral to the EGR system, which helps reduce nitrogen oxides (NOx) by recirculating a portion of the exhaust gases back into the engine’s intake air. Below is a detailed overview of the engines that are compatible with this EGR valve.

Compatible Engines

- B6.7 CM2350 B135B

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISX12 G CM2180 EJ

- QSB6.7 CM2250

Grouping of Compatible Engines

The Cummins EGR Valve 5271307 is compatible with several engines within the Cummins lineup, grouped primarily by their engine series and configurations:

-

B6.7 Series:

- B6.7 CM2350 B135B

- QSB6.7 CM2250

-

ISB6.7 Series:

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

-

ISX12 Series:

- ISX12 G CM2180 EJ

Application Considerations

When installing the Cummins EGR Valve 5271307, it is crucial to ensure that the part is correctly matched with the engine’s specifications and requirements. This compatibility ensures that the EGR system functions effectively, maintaining engine performance and meeting emission standards. Proper installation and maintenance of the EGR valve are essential for the longevity and efficiency of the engine.

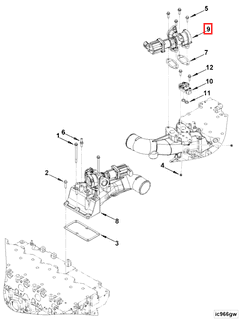

Role of Part 5271307 Exhaust Gas Recirculation Valve in Engine Systems

The Exhaust Gas Recirculation Valve (EGR Valve), identified by part number 5271307, is integral to the operation of modern engine systems. It is strategically positioned within the EGR system to manage the flow of exhaust gases back into the intake manifold.

When the EGR Valve is activated, it allows a measured amount of exhaust gas to be rerouted from the exhaust manifold back into the intake manifold. This process is facilitated through the air intake connection, ensuring a seamless integration with the engine’s air intake system.

The recirculated exhaust gases mix with the fresh air-fuel mixture entering the combustion chamber. This mixture helps in reducing the peak combustion temperature, which in turn lowers the formation of nitrogen oxides (NOx), a significant contributor to air pollution.

The EGR Valve kit, which includes part 5271307, often comes with additional components such as gaskets, mounting brackets, and hoses. These components ensure a secure and efficient installation, maintaining the integrity of the recirculation process.

In summary, the EGR Valve plays a significant role in enhancing engine performance while adhering to environmental regulations by effectively managing exhaust gas recirculation.

Conclusion

The Exhaust Gas Recirculation Valve (Part #5271307) by Cummins is a critical component in modern engine systems, designed to manage exhaust gas recirculation effectively. Its role in reducing emissions, enhancing engine efficiency, and ensuring compliance with environmental regulations underscores its importance in the operation of commercial trucks. Through its robust construction, precision engineering, and seamless integration with Cummins engines, this part contributes to improved fuel efficiency, reduced environmental impact, and enhanced engine performance. Regular maintenance and proper installation are essential to maximize the benefits of this technology.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Williams, D. (2022). Generalized Vehicle Dynamics. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.