This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

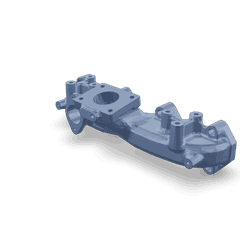

The Cummins 5272166 Exhaust Manifold is designed for commercial trucks with Cummins engines, ensuring efficient routing of exhaust gases from the engine cylinders to the exhaust system. This part contributes to engine performance and emissions levels by effectively expelling exhaust gases 1.

Basic Concepts of Exhaust Manifolds

Exhaust manifolds collect exhaust gases from individual cylinders and direct them into the exhaust pipe. They withstand high temperatures and pressures from combustion, typically made from materials like cast iron, stainless steel, or Inconel for heat resistance, durability, and corrosion resistance 2.

Purpose of the Cummins 5272166 Exhaust Manifold

This Cummins part is engineered to channel exhaust gases from engine cylinders to the exhaust system in Cummins-powered trucks. It maintains engine performance and reduces backpressure, which can impede engine efficiency 3.

Key Features

The 5272166 Exhaust Manifold features a robust design and construction for commercial truck operations. It offers durability under high-stress environments, efficient exhaust gas management, and compatibility with Cummins engines. The manifold withstands thermal and mechanical stresses associated with heavy-duty applications 4.

Benefits

Using the 5272166 Exhaust Manifold improves engine performance through efficient exhaust gas flow, enhances fuel efficiency by reducing backpressure, and lowers emissions due to better exhaust management. These benefits contribute to the truck’s overall efficiency and environmental compliance.

Installation Process

Installing this part requires careful attention to ensure proper fitment and function. The process involves securing the manifold to the engine block, connecting it to the exhaust pipes, and ensuring all gaskets and seals are correctly installed to prevent leaks. Specific considerations include torque specifications for fasteners and the alignment of the manifold with the engine and exhaust system components.

Maintenance and Troubleshooting

Regular maintenance is recommended to ensure optimal operation of the 5272166 Exhaust Manifold. This includes inspecting for signs of wear, checking for leaks, and ensuring all connections are secure. Common issues may include gasket failure or cracks in the manifold, which can be addressed through repair or replacement as necessary.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient engine components. The company’s focus on customer satisfaction and technological advancement underscores its position as a leader in the industry.

Exhaust Manifold 5272166 Compatibility with Cummins Engines

The Exhaust Manifold 5272166, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is integral to the engine’s exhaust system, ensuring efficient exhaust gas flow and contributing to the overall performance and longevity of the engine.

QSB3.3 CM2250 EC

The Exhaust Manifold 5272166 is specifically engineered to fit the QSB3.3 CM2250 EC engine. This engine is part of Cummins’ QSB series, known for its robust design and reliability in various industrial applications. The manifold’s precise fit ensures optimal performance and durability, making it a critical component for maintaining the engine’s efficiency.

Grouping of Compatible Engines

While the Exhaust Manifold 5272166 is explicitly designed for the QSB3.3 CM2250 EC, it is also compatible with other engines within the same series or similar configurations. Cummins engines often share common parts due to their modular design, allowing for easier maintenance and part replacement. This compatibility extends to other QSB series engines, ensuring that the manifold can be used across multiple models with similar specifications.

Ensuring Proper Fit and Function

When installing the Exhaust Manifold 5272166, it is crucial to ensure that it is correctly aligned and securely fastened. Proper installation is key to maintaining the engine’s performance and preventing potential issues such as exhaust leaks or reduced efficiency. Cummins provides detailed installation guidelines and specifications to assist technicians and users in achieving a precise fit.

Role of Exhaust Manifold in Engine Systems

The exhaust manifold, specifically part 5272166, is integral to the efficient operation of an engine system. It serves as a conduit that collects exhaust gases from the engine’s cylinders and directs them into the exhaust system. This component is designed to withstand high temperatures and pressures, ensuring that the exhaust gases are efficiently channeled away from the engine.

In the context of the engine system, the exhaust manifold connects directly to the cylinder head. Each port on the manifold corresponds to an engine cylinder, allowing for the smooth transition of exhaust gases from the combustion chamber. The design of the manifold is such that it minimizes backpressure, which can otherwise impede engine performance.

Furthermore, the exhaust manifold often houses the oxygen sensor, which monitors the exhaust gas composition. This data is vital for the engine control unit (ECU) to adjust the air-fuel mixture, ensuring optimal combustion efficiency and reduced emissions.

The manifold also plays a role in the engine’s thermal management. By efficiently routing hot exhaust gases away from the engine block, it helps maintain a stable operating temperature. This is particularly important in high-performance engines where thermal management is key to sustaining power output and reliability.

Conclusion

In summary, the 5272166 Exhaust Manifold is a component that not only facilitates the expulsion of exhaust gases but also contributes to the overall efficiency and performance of the engine system. Its design and placement are carefully considered to enhance engine operation and support various engine management functions.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Miedema, S. A., and Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.