5282466

Exhaust Gas Recirculation Cooler

Cummins®

IN STOCK

4 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Gas Recirculation (EGR) Cooler, part number 5282466, manufactured by Cummins, is a critical component designed to enhance the performance and efficiency of diesel engines, particularly in heavy-duty trucks. EGR coolers are integral to the operation of diesel engines, managing exhaust gases that are recirculated and cooled before being reintroduced into the engine intake. This process is essential for reducing emissions and improving engine efficiency.

Function and Operation of EGR Coolers

EGR coolers operate by taking a portion of the exhaust gases produced by the engine and cooling them before they are mixed with the fresh air intake. This cooled exhaust gas is then reintroduced into the combustion chamber. The EGR cooler facilitates this process by reducing the temperature of the recirculated gases, which helps in lowering the combustion temperature within the engine. This reduction in temperature contributes to decreasing the formation of nitrogen oxides (NOx), a common pollutant produced during combustion 1.

Purpose of the 5282466 EGR Cooler

The 5282466 EGR Cooler is specifically designed to contribute to the reduction of NOx emissions and enhance engine efficiency in trucks. By cooling the recirculated exhaust gases, this Cummins part helps in maintaining optimal combustion conditions, which leads to lower emissions and improved fuel efficiency. Its role is vital in ensuring that the engine operates within regulatory standards for emissions while also maximizing performance 2.

Key Features

The 5282466 EGR Cooler is constructed using high-quality materials that ensure durability and performance. Its design incorporates elements that enhance heat exchange efficiency, such as a compact core and efficient flow paths. These features contribute to the cooler’s ability to effectively reduce the temperature of exhaust gases. Additionally, the 5282466 model may include specific design characteristics that optimize its performance for heavy-duty applications.

Benefits of Using an EGR Cooler

The use of EGR coolers in diesel engines offers several benefits. Primarily, they contribute to a significant reduction in NOx emissions, which is crucial for compliance with environmental regulations. Additionally, EGR coolers can improve fuel efficiency by allowing the engine to operate more efficiently under varying conditions. The integration of an EGR cooler into the engine system also supports long-term engine health by reducing the thermal stress on engine components 1.

Installation and Integration

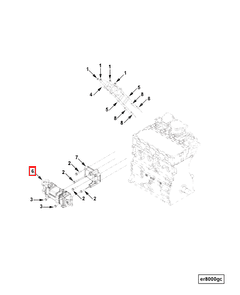

Proper installation of the 5282466 EGR Cooler is important for ensuring its effectiveness and compatibility with the engine system. Guidelines for installation should be followed to ensure that the cooler is correctly positioned and connected within the engine’s exhaust and intake systems. Compatibility with various engine models should be considered to ensure optimal performance and integration.

Maintenance and Troubleshooting

Regular maintenance of the 5282466 EGR Cooler is important for its longevity and efficiency. This includes periodic inspections for signs of wear or damage, cleaning to remove any buildup that may impede performance, and ensuring all connections are secure. Common issues such as blockages or leaks can be addressed through routine checks and timely repairs. Troubleshooting tips may include verifying the cooler’s temperature differential and ensuring there are no obstructions in the flow paths.

Performance and Efficiency

The 5282466 EGR Cooler contributes to the overall performance and efficiency of the engine by effectively managing exhaust gas temperatures. Data on emission reductions and fuel savings when using this component can demonstrate its impact on engine operation. The cooler’s ability to reduce NOx emissions while maintaining or improving fuel efficiency underscores its value in modern diesel engine systems.

Environmental Impact

The use of EGR coolers, such as the 5282466 model, has a positive environmental impact by reducing the carbon footprint of heavy-duty trucks. By lowering NOx emissions, these coolers help in mitigating the environmental effects associated with diesel engine operation. The specific design and efficiency of the 5282466 EGR Cooler play a role in these environmental benefits, contributing to cleaner air and compliance with emissions standards 2.

Cummins: A Brief Overview

Cummins Inc., the manufacturer of the 5282466 EGR Cooler, is a leader in diesel engine technology with a history of innovation and commitment to sustainability. The company’s expertise in engine design and component manufacturing is evident in the quality and performance of its products. Cummins continues to advance diesel technology, focusing on efficiency, reliability, and environmental responsibility.

Conclusion

The Exhaust Gas Recirculation (EGR) Cooler, part number 5282466, is a vital component in the engine systems of various Cummins engines, including the QSB3.3 CM2250 EC. This part is designed to manage the temperature of exhaust gases that are recirculated back into the engine’s intake system. Its primary function is to cool the exhaust gases before they are reintroduced into the combustion process, which helps in reducing nitrogen oxide (NOx) emissions and improving engine efficiency.

In the context of the QSB3.3 CM2250 EC engine, the EGR Cooler part 5282466 plays a significant role in maintaining optimal engine performance and compliance with emission standards. The cooler is strategically positioned within the engine’s exhaust system, ensuring that it effectively cools the recirculated gases. This positioning is critical for the engine’s overall operation, as it directly impacts the efficiency of the EGR system and the engine’s ability to meet regulatory requirements.

The integration of the EGR Cooler part 5282466 into the engine system is a testament to Cummins’ commitment to innovation and environmental responsibility. By incorporating this component, Cummins ensures that their engines not only perform at high levels but also contribute to reducing the environmental impact of diesel engines. The design and placement of this part within the engine system reflect Cummins’ expertise in engineering solutions that balance performance with sustainability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.