This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

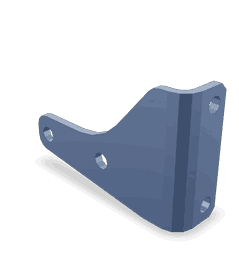

The Exhaust Recirculation Cooler Bracket, identified by part number 5282468, is a component manufactured by Cummins. This bracket plays a role in the exhaust recirculation system by securely mounting the cooler, which is responsible for cooling the recirculated exhaust gases before they are reintroduced into the engine’s intake system 1. Cummins, a well-established name in the automotive industry, is known for its commitment to producing high-quality components designed to enhance the performance and efficiency of commercial trucks.

Function and Operation

The Exhaust Recirculation Cooler Bracket operates within the exhaust recirculation system by providing a stable mounting point for the cooler. This system works by recirculating a portion of the engine’s exhaust gases back into the intake system. The cooler, mounted on the bracket, reduces the temperature of these gases, which helps in lowering nitrogen oxide emissions and improving fuel efficiency 2. The bracket ensures that the cooler remains securely in place, allowing it to effectively manage exhaust gases and contribute to emission control.

Key Features

The Exhaust Recirculation Cooler Bracket is designed with several features that enhance its performance and durability. It is constructed from high-strength materials to withstand the harsh conditions of the exhaust system. The bracket’s design allows for easy installation and ensures a secure fit, minimizing the risk of vibrations or movement that could affect the cooler’s efficiency. Additionally, the bracket is engineered to be compatible with a variety of truck models and engine types, providing versatility in its application.

Benefits

The Exhaust Recirculation Cooler Bracket offers several advantages. By securely mounting the cooler, it contributes to improved engine efficiency and reduced emissions. The effective cooling of recirculated exhaust gases leads to lower nitrogen oxide emissions, helping trucks meet stringent emissions regulations 3. Furthermore, the bracket’s robust construction and design enhance the overall performance and reliability of the exhaust recirculation system.

Installation and Compatibility

Proper installation of the Exhaust Recirculation Cooler Bracket is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and optimal performance. The bracket is designed to be compatible with a range of truck models and engine types, making it a versatile component for various applications. Specific installation requirements may vary depending on the truck model, so it is important to consult the installation manual for detailed instructions.

Maintenance and Troubleshooting

Routine maintenance of the Exhaust Recirculation Cooler Bracket is important to ensure its optimal functioning. Regular inspections should be conducted to check for any signs of wear or damage. Common issues may include loose mounting or corrosion, which can be addressed by tightening the bracket or applying a protective coating. If any problems are detected, it is recommended to consult a professional technician for repairs or replacements to maintain the efficiency of the exhaust recirculation system.

Regulatory Compliance

The Exhaust Recirculation Cooler Bracket helps trucks comply with regulatory standards and emissions regulations. By effectively mounting the cooler, it plays a role in reducing nitrogen oxide emissions, which is a key factor in meeting environmental and safety requirements. Cummins is committed to producing components that not only enhance vehicle performance but also ensure compliance with regulatory standards, contributing to a cleaner and safer operating environment.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for commercial trucks. The company is known for its innovation, reliability, and commitment to excellence. Cummins’ reputation is built on its ability to deliver products that meet the demanding requirements of the industry, ensuring that commercial trucks operate efficiently and reliably. The Exhaust Recirculation Cooler Bracket is a testament to Cummins’ dedication to quality and performance in the automotive sector.

Exhaust Recirculation Cooler Bracket (Part 5282468) Compatibility with Cummins Engines

The Exhaust Recirculation Cooler Bracket, identified by part number 5282468, is a critical component in the exhaust recirculation system of certain Cummins engines. This bracket is designed to securely mount the exhaust recirculation cooler, ensuring that it remains in the correct position to effectively manage exhaust gas temperatures.

QSB3.3 CM2250 EC

The QSB3.3 CM2250 EC engine is one of the models that utilize the Exhaust Recirculation Cooler Bracket 5282468. This engine is part of Cummins’ QSB series, known for its robust performance and reliability in various industrial and commercial applications. The bracket’s role in this engine is to maintain the structural integrity of the exhaust recirculation system, which is essential for optimizing engine performance and reducing emissions.

Grouping of Engines

While the Exhaust Recirculation Cooler Bracket 5282468 is specifically designed for the QSB3.3 CM2250 EC engine, it is also compatible with other engines within the same series or similar models that share the same design and specifications. Cummins engines often share components across different models to ensure consistency and ease of maintenance. Therefore, it is advisable to verify compatibility with other models within the same engine series before making any replacements or repairs.

Role of Part 5282468 Exhaust Recirculation Cooler Bracket in Engine Systems

The Exhaust Recirculation Cooler Bracket, identified by part number 5282468, is an essential component in the orchestration of several key engine systems. Its primary function is to provide a secure mounting point for the Exhaust Gas Recirculation (EGR) cooler, ensuring that the cooler remains firmly in place and properly aligned within the engine bay.

Integration with Engine Components

-

Mounting: The bracket is designed to interface with various mounting points on the engine block or chassis. This secure attachment is vital for maintaining the structural integrity of the EGR system, allowing it to withstand the vibrations and thermal stresses encountered during engine operation.

-

Exhaust Gas Recirculation (EGR) System: The EGR system plays a significant role in reducing nitrogen oxides (NOx) emissions by recirculating a portion of the exhaust gas back into the intake manifold. The Exhaust Recirculation Cooler Bracket supports the EGR cooler, which is responsible for cooling the recirculated exhaust gases before they are mixed with the intake air. This cooling process enhances the efficiency of the EGR system and helps in meeting emissions regulations.

-

Engine Control Module (ECM): The ECM monitors and controls various engine parameters, including the operation of the EGR system. The stable mounting provided by the Exhaust Recirculation Cooler Bracket ensures that the EGR cooler functions as intended, allowing the ECM to accurately regulate the recirculation process. This, in turn, contributes to optimal engine performance and emissions control.

-

Thermal Management: By supporting the EGR cooler, the bracket aids in the thermal management of the engine. The cooler helps in dissipating heat from the recirculated exhaust gases, which can otherwise lead to increased engine temperatures and potential damage. The bracket’s role in maintaining the cooler’s position is therefore integral to the overall thermal management strategy of the engine.

Conclusion

In summary, the Exhaust Recirculation Cooler Bracket (part number 5282468) is a pivotal component that ensures the proper functioning and integration of the EGR system within the engine. Its role in providing a stable mounting solution directly impacts the efficiency of exhaust gas recirculation, thermal management, and overall engine performance.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.