This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

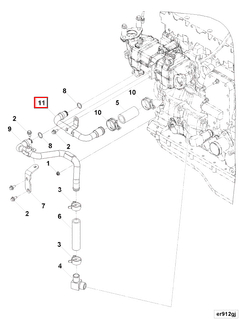

The Exhaust Cooler Water Inlet Tube, identified by part number 5284576, is a component manufactured by Cummins. This tube is integral to the exhaust cooling system, facilitating the efficient management of exhaust gases and coolant flow to enhance engine performance and reduce emissions 1.

Function and Operation

The Exhaust Cooler Water Inlet Tube operates by directing coolant into the exhaust cooler. As exhaust gases pass through the cooler, the coolant absorbs heat, reducing the temperature of the gases before they exit the system. This process involves the coolant flowing through the tube into the cooler, where it interacts with the hot exhaust gases, effectively lowering their temperature 2.

Purpose of the Exhaust Cooler Water Inlet Tube

This Cummins part plays a role in the overall operation of a truck by contributing to engine efficiency and emissions reduction. By cooling the exhaust gases, the tube helps maintain optimal engine temperatures and reduces the emission of harmful pollutants, aligning with environmental regulations and improving overall engine performance 3.

Key Features

The primary features of the Exhaust Cooler Water Inlet Tube include its durable material composition, typically made from high-quality metals to withstand high temperatures and pressures. The design elements of the tube ensure a secure fit within the exhaust system, promoting efficient coolant flow. Unique attributes such as corrosion-resistant coatings enhance its performance and longevity.

Benefits

The advantages provided by the Exhaust Cooler Water Inlet Tube include improved engine performance through effective cooling of exhaust gases, reduced emissions contributing to environmental compliance, and enhanced durability ensuring long-term reliability in demanding conditions.

Installation Process

Proper installation of the Exhaust Cooler Water Inlet Tube involves several steps. First, ensure the engine is cool and the system is depressurized. Next, locate the inlet tube connection point within the exhaust cooling system. Carefully align the tube with the connection, ensuring a snug fit to prevent leaks. Secure the tube using the appropriate fasteners, and finally, test the system for proper coolant flow and seal integrity.

Common Issues and Troubleshooting

Frequent problems associated with the Exhaust Cooler Water Inlet Tube may include leaks, corrosion, or blockages. Troubleshooting methods involve inspecting the tube for signs of wear or damage, checking connections for tightness, and ensuring the coolant flow is unobstructed. Solutions may include repairing or replacing damaged sections, applying corrosion inhibitors, or cleaning the tube to remove any debris.

Maintenance Tips

To ensure the longevity and optimal performance of the Exhaust Cooler Water Inlet Tube, regular maintenance practices are recommended. These include periodic inspections for signs of wear or corrosion, ensuring all connections are tight and secure, and maintaining the coolant system to prevent blockages. Additionally, following the manufacturer’s guidelines for coolant type and replacement intervals can enhance the tube’s durability.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of innovation and quality. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, known for their reliability and performance. Cummins’ reputation is built on a commitment to excellence, providing solutions that meet the demanding needs of the transportation sector.

Exhaust Cooler Water Inlet Tube (Part 5284576) Compatibility with Cummins Engines

The Exhaust Cooler Water Inlet Tube (Part 5284576) is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the flow of coolant into the exhaust cooler, ensuring efficient heat dissipation and optimal engine performance.

QSB4.5 CM2250 EC

The QSB4.5 CM2250 EC engine is one of the models that benefit from the precise engineering of the Exhaust Cooler Water Inlet Tube. This part is integral to maintaining the engine’s thermal efficiency by ensuring that the coolant enters the exhaust cooler at the correct pressure and flow rate.

Grouping of Compatible Engines

The Exhaust Cooler Water Inlet Tube (Part 5284576) is compatible with a range of Cummins engines that share similar design and operational parameters. These engines include, but are not limited to, the following:

- QSB4.5 Series: This series of engines is known for its robust performance and reliability in various industrial applications. The inlet tube ensures that the exhaust cooler operates effectively, contributing to the engine’s longevity and efficiency.

- CM2250 Series: Part of the Cummins Medium Duty lineup, these engines are designed for heavy-duty applications. The inlet tube’s role in facilitating coolant flow is crucial for maintaining optimal operating temperatures and preventing overheating.

By integrating the Exhaust Cooler Water Inlet Tube (Part 5284576) into these engines, Cummins ensures that the cooling system functions seamlessly, providing reliable performance and extending the engine’s operational life.

Role of Part 5284576 Exhaust Cooler Water Inlet Tube in Engine Systems

The Exhaust Cooler Water Inlet Tube (part 5284576) is an integral component in the efficient operation of exhaust cooler systems within engine setups. Its primary function is to direct coolant into the exhaust cooler, ensuring optimal thermal management of the exhaust gases.

Integration with Exhaust Cooler Water Outlet Tube

Once the coolant has absorbed heat from the exhaust gases within the cooler, it exits through the Exhaust Cooler Water Outlet Tube. This tube is positioned downstream of the inlet tube, facilitating a continuous coolant flow that effectively regulates the temperature of the exhaust stream. The synergy between the inlet and outlet tubes ensures a consistent coolant circulation, which is vital for maintaining the cooler’s efficiency and prolonging its service life.

Role in Exhaust Recirculation Water Plumbing

In systems that incorporate Exhaust Recirculation (EGR), the Exhaust Cooler Water Inlet Tube plays a supportive role. EGR systems reroute a portion of the exhaust gases back into the engine’s intake to reduce nitrogen oxides (NOx) emissions. The coolant supplied by the inlet tube helps in cooling these recirculated gases, making them less harmful and more manageable for the engine. This integration enhances the overall effectiveness of the EGR system by ensuring that the recirculated gases are at an optimal temperature before entering the combustion chamber again.

Contribution to Overall Engine Efficiency

By maintaining the exhaust cooler at an efficient operating temperature, the Exhaust Cooler Water Inlet Tube indirectly contributes to the engine’s overall performance. Efficient cooling of exhaust gases allows the engine to operate within its designed thermal parameters, reducing the risk of overheating and associated mechanical failures. Moreover, it aids in meeting stringent emission standards by ensuring that exhaust gases are cooled sufficiently before they are released into the atmosphere.

Conclusion

The Exhaust Cooler Water Inlet Tube (part 5284576) is a key component in the thermal management of engine exhaust systems. Its effective integration with other components like the Exhaust Cooler Water Outlet Tube and its role in Exhaust Recirculation Water Plumbing underscore its importance in enhancing engine performance and emissions control.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.