This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

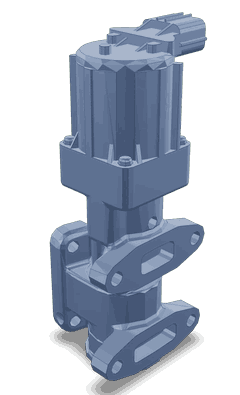

The Exhaust Gas Recirculation Valve 5292034RX, manufactured by Cummins, is designed to manage the flow of exhaust gases back into the engine’s intake. This process optimizes engine performance and reduces emissions, making it a critical component in the automotive and heavy-duty truck industry 1.

Basic Concepts of Exhaust Gas Recirculation Valves

Exhaust Gas Recirculation (EGR) Valves are essential in diesel engines, redirecting a portion of the exhaust gas back into the intake manifold. This reduces the concentration of oxygen in the intake air, lowering combustion temperature and the formation of nitrogen oxides (NOx). EGR Valves contribute to more efficient and cleaner engine operation by managing these emissions 4.

Role of the 5292034RX Exhaust Gas Recirculation Valve in Truck Operation

This Cummins part is engineered to enhance commercial truck operation by regulating the amount of exhaust gas recirculated. This regulation maintains optimal combustion conditions, reducing NOx levels and contributing to improved engine performance and fuel efficiency. The valve’s precise control over gas flow ensures the engine operates within desired parameters, balancing power output and emissions 3.

Key Features of the 5292034RX Exhaust Gas Recirculation Valve

The 5292034RX incorporates advanced materials for durability and resistance to harsh diesel engine conditions. Technological advancements in its construction allow for more precise control over gas flow, enhancing efficiency. The valve is engineered to integrate seamlessly with Cummins engines, ensuring compatibility and optimal performance 2.

Benefits of Using the 5292034RX Exhaust Gas Recirculation Valve

Using this part offers several benefits, including improved fuel efficiency through optimized combustion and reduced emissions, helping trucks meet stringent environmental regulations. The valve’s design and materials also contribute to enhanced engine longevity, providing reliable performance over extended periods 1.

Installation and Integration

Proper installation of the 5292034RX is crucial for its effective operation. It should be integrated into the truck’s engine system according to manufacturer guidelines to ensure compatibility and optimal performance. Specific requirements may include precise alignment and secure mounting to withstand engine vibrations and maintain a seal against exhaust gases 2.

Troubleshooting and Maintenance

Common issues with the 5292034RX may include blockages or malfunctions due to carbon buildup. Regular maintenance practices, such as cleaning and inspection, can help prevent these issues. Troubleshooting may involve checking for proper valve operation and ensuring there are no leaks in the system. Adhering to maintenance schedules can ensure the valve’s longevity and continued efficient operation 3.

Regulatory Compliance and Emissions Standards

The 5292034RX plays a role in helping trucks meet regulatory compliance and emissions standards by reducing NOx emissions. Compliance with these standards is achieved through rigorous testing procedures that ensure the valve’s effectiveness in emissions reduction 4.

Conclusion

The 5292034RX Exhaust Gas Recirculation Valve by Cummins is a vital component in optimizing engine performance and reducing emissions in commercial trucks. Its advanced features, benefits, and role in regulatory compliance make it a valuable asset for truck operators seeking efficient and environmentally friendly engine operation.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ ↩ -

Cummins. (n.d.). Operation and Maintenance Manual for QSB6.7 CM2250 B128. Bulletin Number 4388602.

↩ ↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ ↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.