This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

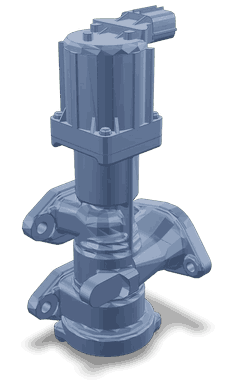

The Cummins 5306676 Exhaust Gas Recirculation Valve is a component designed to enhance the operation of commercial trucks. Its purpose is to manage the recirculation of exhaust gases back into the engine’s intake, which plays a role in reducing emissions and improving engine efficiency. This valve is significant in the context of modern truck engines, where stringent emissions regulations and fuel efficiency are paramount.

Basic Concepts of Exhaust Gas Recirculation Valves

An Exhaust Gas Recirculation (EGR) Valve is a device that reroutes a portion of an engine’s exhaust gas back into the intake manifold. This process dilutes the oxygen in the intake air, which lowers the combustion temperature and reduces the formation of nitrogen oxides (NOx), a common pollutant. Additionally, EGR contributes to engine efficiency by allowing for more complete combustion of the fuel-air mixture 1.

Purpose of the Cummins 5306676 Exhaust Gas Recirculation Valve

The Cummins 5306676 Exhaust Gas Recirculation Valve is specifically engineered to integrate seamlessly with Cummins engines found in commercial trucks. It facilitates the recirculation of exhaust gases, which helps in lowering emissions by reducing NOx levels. Furthermore, it contributes to maintaining engine performance by ensuring efficient combustion processes.

Key Features

The Cummins 5306676 Exhaust Gas Recirculation Valve is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. It features precision engineering to provide accurate control over the flow of exhaust gases. Additionally, the valve incorporates advanced sealing mechanisms to prevent leaks and ensure consistent performance over time.

Benefits

Utilizing the Cummins 5306676 Exhaust Gas Recirculation Valve offers several advantages. It contributes to improved fuel efficiency by optimizing the combustion process. The valve also aids in reducing emissions, helping trucks meet regulatory standards. Moreover, by promoting efficient combustion, it enhances engine longevity, reducing the need for frequent maintenance and replacements.

Installation Process

Installing the Cummins 5306676 Exhaust Gas Recirculation Valve requires careful attention to detail. The process involves disconnecting the old valve, ensuring the intake manifold is clean, and securely attaching the new valve. Proper tools and prerequisites, such as gaskets and seals, are necessary to ensure a leak-free installation. Following the manufacturer’s guidelines is recommended to achieve optimal performance.

Troubleshooting Common Issues

Common issues with the Cummins 5306676 Exhaust Gas Recirculation Valve may include blockages, leaks, or malfunctions due to carbon buildup. Troubleshooting steps involve inspecting the valve for obstructions, checking for proper sealing, and ensuring the valve operates within specified parameters. Regular maintenance and cleaning can prevent many of these issues.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 5306676 Exhaust Gas Recirculation Valve, regular maintenance is advised. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any carbon deposits, and ensuring all connections are secure and leak-free. Adhering to the manufacturer’s maintenance schedule will help maintain efficiency and reliability.

Impact on Engine Performance

The Cummins 5306676 Exhaust Gas Recirculation Valve influences engine performance by contributing to more efficient combustion and reduced emissions. This can lead to improvements in power output and fuel consumption. The valve’s role in managing exhaust gas recirculation ensures that the engine operates within optimal parameters, enhancing overall efficiency.

Environmental Considerations

The use of the Cummins 5306676 Exhaust Gas Recirculation Valve contributes to environmental sustainability by reducing emissions. Lower NOx levels help in minimizing the environmental impact of commercial trucks. Compliance with environmental regulations is facilitated through the effective operation of this valve, demonstrating a commitment to greener transportation solutions.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a diverse product range, Cummins is committed to advancing technology in the automotive industry. The company’s focus on efficiency, reliability, and environmental responsibility is reflected in its extensive lineup of components, including the Cummins 5306676 Exhaust Gas Recirculation Valve.

Compatibility

The Cummins Exhaust Gas Recirculation (EGR) Valve, part number 5306676, is designed to manage the recirculation of exhaust gases back into the engine’s intake system, which helps reduce nitrogen oxide (NOx) emissions and improve overall engine efficiency. This part is compatible with various Cummins engines, including the B6.7 CM2350 and B135B engines, as well as the ISX12 G CM2180 EJ engines.

Role in Engine Systems

The Exhaust Gas Recirculation (EGR) Valve, identified by part number 5306676, is a pivotal component in modern engine systems, designed to reduce nitrogen oxides (NOx) emissions by recirculating a portion of the exhaust gas back into the intake manifold. This process dilutes the oxygen content in the intake charge, thereby lowering combustion temperatures and reducing NOx formation.

When the EGR valve is activated, it allows a measured amount of exhaust gas to flow from the exhaust manifold into the intake manifold. This recirculated gas mixes with the fresh air-fuel mixture before it enters the combustion chamber. The EGR system typically includes a control module that monitors various engine parameters such as engine load, coolant temperature, and intake air temperature to determine the optimal amount of EGR flow.

The EGR valve works in conjunction with several other components to ensure efficient operation. The EGR cooler, often integrated into the system, cools the recirculated exhaust gases before they enter the intake manifold, which helps to further reduce combustion temperatures and improve engine efficiency. Additionally, the EGR differential pressure sensor measures the pressure difference across the EGR valve, providing feedback to the engine control unit (ECU) to adjust the valve’s position as needed.

In diesel engines, the EGR system is often paired with a Diesel Particulate Filter (DPF) and a Selective Catalytic Reduction (SCR) system. The EGR valve helps to lower the exhaust temperature, which can reduce the frequency of DPF regeneration cycles. Meanwhile, the SCR system uses a urea-based solution to convert NOx into harmless nitrogen and water, complementing the EGR system’s efforts to meet stringent emissions standards.

Overall, the 5306676 EGR valve is an essential component that enhances engine performance while ensuring compliance with environmental regulations. Its integration with other engine systems underscores the complexity and sophistication of modern automotive engineering.

Conclusion

The Cummins 5306676 Exhaust Gas Recirculation Valve is a critical component in the emissions control system of various Cummins engines. It plays a significant role in reducing NOx emissions and improving engine efficiency. By integrating this valve into the engine system, users can expect enhanced performance and compliance with stringent emissions standards. Regular maintenance and proper installation are key to ensuring the optimal performance and longevity of this part.

-

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.