This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

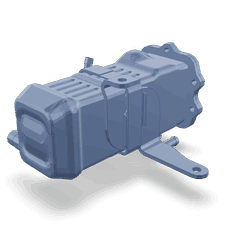

The Cummins 5310100 Exhaust Gas Recirculation (EGR) Cooler is designed to enhance the operation of commercial trucks by integrating into the EGR system. Its primary role is to reduce emissions and improve engine efficiency, contributing to both environmental and performance objectives in heavy-duty applications.

Basic Concepts of Exhaust Gas Recirculation Coolers

Exhaust Gas Recirculation (EGR) Coolers operate on the principle of recirculating a portion of the exhaust gas back into the engine’s intake. This process dilutes the oxygen concentration in the intake charge, which lowers combustion temperatures and reduces the formation of nitrogen oxides (NOx), a harmful emission 1. The EGR Cooler plays a role in this system by cooling the recirculated exhaust gases before they are reintroduced into the intake system, which helps maintain optimal engine performance and efficiency.

Purpose and Functionality

The Cummins 5310100 EGR Cooler is specifically engineered to fit within the EGR system of truck engines. It contributes to emission reduction by cooling the recirculated exhaust gases, which helps in lowering combustion temperatures and, consequently, NOx emissions. Additionally, by optimizing the temperature of the intake charge, the cooler aids in improving engine efficiency and performance 2.

Key Features

The Cummins 5310100 EGR Cooler incorporates several design elements and materials that enhance its performance and durability. It is constructed using high-quality materials resistant to corrosion and thermal stress, ensuring longevity in demanding operating conditions. The design includes efficient heat exchange capabilities, allowing for effective cooling of the exhaust gases. Unique characteristics such as compact size and robust construction further contribute to its reliability and performance.

Benefits of Using the Cummins 5310100 EGR Cooler

Utilizing the Cummins 5310100 EGR Cooler offers several advantages. It contributes to improved fuel efficiency by optimizing engine performance. Reduced emissions are another significant benefit, aligning with environmental regulations and promoting cleaner air quality. Additionally, the cooler enhances engine longevity by maintaining optimal operating temperatures and reducing thermal stress on engine components 3.

Installation and Integration

Proper installation and integration of the Cummins 5310100 EGR Cooler within a truck’s engine system are vital for ensuring optimal performance. Guidelines recommend following manufacturer specifications for mounting and connecting the cooler to the EGR system. Best practices include verifying all connections are secure and leak-free, and ensuring the cooler is properly aligned within the engine bay to avoid obstructions and ensure efficient airflow.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 5310100 EGR Cooler is important for sustained performance. Regular inspections should check for signs of corrosion, leaks, or blockages within the cooler. Common issues may include reduced cooling efficiency or increased emissions, which can often be traced back to deposits or obstructions within the cooler. Troubleshooting tips include cleaning the cooler and ensuring all connections are intact and functioning correctly.

Performance Monitoring

Monitoring the performance of the Cummins 5310100 EGR Cooler is crucial for identifying potential problems early. Indicators of issues may include changes in engine performance, increased emissions, or unusual noises from the cooler. Regular checks and diagnostic tests can help ensure the cooler continues to operate efficiently, contributing to overall engine health and emissions compliance.

Environmental Impact

The use of the Cummins 5310100 EGR Cooler has positive environmental implications. By reducing NOx emissions, it contributes to cleaner air quality and helps meet stringent emissions regulations. The cooler’s role in promoting efficient engine operation also indirectly supports fuel conservation efforts, furthering its environmental benefits.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation in engine technology and a commitment to reducing emissions, Cummins continues to develop advanced solutions for the transportation and power generation industries. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial and industrial applications.

Exhaust Gas Recirculation Cooler Compatibility with Cummins Engines

The Exhaust Gas Recirculation (EGR) Cooler part number 5310100, manufactured by Cummins, is designed to fit seamlessly with several specific engine models. This part plays a role in the EGR system by cooling the recirculated exhaust gases before they are reintroduced into the engine’s combustion process. This cooling process helps to reduce the formation of nitrogen oxides (NOx) and improve overall engine efficiency.

ISF2.8 CM2220 F117 and ISF2.8 CM2220 F129

The EGR Cooler part number 5310100 is compatible with the ISF2.8 CM2220 engines, specifically the F117 and F129 variants. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The EGR Cooler’s design ensures it fits perfectly within the architecture of these engines, providing efficient cooling and contributing to the overall emission reduction strategy.

R2.8 CM2220 R101B

Similarly, the R2.8 CM2220 R101B engine also benefits from the integration of the EGR Cooler part number 5310100. This engine variant is engineered for high performance and durability, making it suitable for various demanding applications. The EGR Cooler’s precise fit and function within this engine model help maintain optimal operating temperatures and enhance the engine’s environmental performance.

By ensuring a perfect fit with these specific engine models, the EGR Cooler part number 5310100 from Cummins maintains the integrity and efficiency of the EGR system, contributing to the overall performance and longevity of the engines.

Role of Part 5310100 Exhaust Gas Recirculation Cooler in Engine Systems

The Exhaust Gas Recirculation (EGR) Cooler, identified by part number 5310100, is an integral component in the EGR system of modern engines. It works in conjunction with the EGR module and the EGR recirculation kit to optimize engine performance and emissions.

Integration with the EGR Module

The EGR module is responsible for regulating the flow of exhaust gases that are recirculated back into the intake manifold. The EGR Cooler, part 5310100, is positioned within this system to cool the recirculated exhaust gases before they mix with the fresh air-fuel mixture. This cooling process reduces the temperature of the exhaust gases, which helps in lowering NOx emissions and preventing engine knocking.

Function within the EGR Recirculation Kit

The EGR Recirculation Kit typically includes various components designed to manage the flow and temperature of the recirculated exhaust gases. The EGR Cooler plays a significant role here by ensuring that the gases are at an optimal temperature when they re-enter the combustion chamber. This not only enhances engine efficiency but also prolongs the lifespan of other engine components by reducing thermal stress.

Overall Impact on Recirculation Process

In the recirculation process, the EGR Cooler ensures that the exhaust gases are not only redirected but also conditioned to meet the requirements of the combustion process. By reducing the temperature of these gases, the cooler helps maintain a stable combustion environment, which is essential for consistent engine performance and reduced emissions.

Conclusion

In summary, part 5310100 Exhaust Gas Recirculation Cooler is a key component that enhances the functionality of the EGR system by cooling the recirculated exhaust gases, thereby contributing to improved engine efficiency and reduced emissions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.