This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

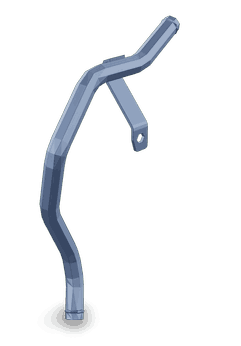

The Exhaust Cooler Water Inlet Tube (5318709) by Cummins is a component designed for use in the exhaust cooling systems of heavy-duty trucks. Its purpose is to facilitate the efficient flow of coolant into the exhaust cooler, which plays a role in reducing the temperature of exhaust gases before they exit the vehicle. This component is integral to maintaining optimal engine performance and ensuring compliance with emissions standards 1.

Function and Operation

The Exhaust Cooler Water Inlet Tube operates by directing coolant from the engine’s cooling system into the exhaust cooler. As exhaust gases pass through the cooler, the coolant absorbs heat, which is then dissipated through the cooling system. This process reduces the temperature of the exhaust gases, contributing to lower emissions and improved engine efficiency. The tube’s design ensures a consistent flow of coolant, which is crucial for the effective operation of the exhaust cooling system 2.

Key Features

The Exhaust Cooler Water Inlet Tube is constructed from durable materials that resist corrosion and withstand high temperatures and pressures. Its design includes precise fittings and connections that ensure a secure and leak-free installation. The tube is also engineered to accommodate the thermal expansion and contraction that occur during engine operation, which helps maintain its integrity over time.

Role in Truck Operation

In the operation of a heavy-duty truck, the Exhaust Cooler Water Inlet Tube contributes to engine efficiency by aiding in the reduction of exhaust gas temperatures. This not only helps in meeting emissions regulations but also protects other components in the exhaust system from thermal stress. Additionally, by maintaining lower exhaust temperatures, the tube supports the overall performance and longevity of the engine.

Benefits

Using the Exhaust Cooler Water Inlet Tube offers several benefits. It enhances engine cooling efficiency, which can lead to improved performance and reduced wear on engine components. The tube’s durable construction and design contribute to its longevity, potentially offering cost savings over time by reducing the need for frequent replacements. Moreover, its role in emissions reduction supports environmental compliance and can contribute to a truck’s overall operational efficiency.

Installation and Compatibility

Proper installation of the Exhaust Cooler Water Inlet Tube is vital for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings for fasteners and the use of compatible sealants to prevent leaks. Ensuring compatibility with other system components is also important to maintain the integrity of the exhaust cooling system.

Maintenance and Troubleshooting

Regular maintenance of the Exhaust Cooler Water Inlet Tube involves inspecting it for signs of wear, corrosion, or leaks. Common issues may include blockages in the coolant flow or damage to the tube itself. Troubleshooting these issues typically involves cleaning or replacing the tube as necessary. Adhering to recommended inspection intervals can help identify potential problems before they lead to more significant issues.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product line and technological advancements have made it a preferred choice for heavy-duty truck manufacturers and operators worldwide.

Exhaust Cooler Water Inlet Tube for Cummins Engines

The Exhaust Cooler Water Inlet Tube, part number 5318709, is a critical component in the cooling systems of certain Cummins engines. This part is designed to facilitate the flow of coolant into the exhaust cooler, ensuring efficient heat dissipation and maintaining optimal engine performance.

Application in Cummins Engines

The Exhaust Cooler Water Inlet Tube is compatible with the following Cummins engines:

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

In these engines, the Exhaust Cooler Water Inlet Tube is integral to the exhaust gas recirculation (EGR) system. It connects the water supply to the exhaust cooler, allowing coolant to flow through and absorb heat from the exhaust gases. This process helps to reduce the temperature of the exhaust gases before they are recirculated back into the engine, thereby improving fuel efficiency and reducing emissions.

The design of the Exhaust Cooler Water Inlet Tube ensures a secure and leak-proof connection, which is essential for maintaining the integrity of the cooling system. It is manufactured to meet stringent quality standards, ensuring durability and reliability in demanding engine environments.

By integrating seamlessly with the exhaust cooler, this part plays a vital role in the overall cooling strategy of the engine, contributing to its longevity and performance.

Role of Part 5318709 Exhaust Cooler Water Inlet Tube in Engine Systems

The Exhaust Cooler Water Inlet Tube, identified by part number 5318709, is an integral component in the efficient operation of engine systems that incorporate exhaust gas recirculation (EGR) and water-cooled exhaust systems. This component is responsible for directing water into the exhaust cooler, ensuring optimal cooling of the recirculated exhaust gases before they are reintroduced into the combustion process.

Integration with Plumbing Systems

In the context of engine plumbing, the Exhaust Cooler Water Inlet Tube interfaces with the water supply lines, facilitating the flow of coolant into the exhaust cooler. This connection is vital for maintaining the correct temperature and pressure within the cooler, which in turn ensures the EGR system operates within specified parameters. The tube’s design allows for a secure and leak-free connection, which is essential for the longevity and reliability of the engine’s cooling system.

Function within Exhaust Recirculation Water Systems

When considering exhaust recirculation water systems, the role of the Exhaust Cooler Water Inlet Tube becomes even more pronounced. The tube is a key conduit for the water that cools the exhaust gases as they pass through the cooler. This cooling process is necessary to reduce the temperature of the exhaust gases to a level that is safe for reinjection into the engine’s intake tract. The efficient flow of water through the inlet tube directly impacts the effectiveness of the EGR system in reducing emissions and improving fuel efficiency.

The Exhaust Cooler Water Inlet Tube must be meticulously engineered to withstand the high temperatures and pressures associated with exhaust systems. Its material and construction are designed to resist corrosion and maintain structural integrity over the engine’s operational life. The tube’s placement within the system is also strategic, ensuring that water is delivered to the cooler at the optimal point for maximum cooling efficiency.

Conclusion

In summary, the Exhaust Cooler Water Inlet Tube (part 5318709) is a specialized component that plays a significant role in the plumbing and exhaust recirculation water systems of an engine. Its function is to provide a reliable pathway for coolant to enter the exhaust cooler, which is essential for the proper functioning of the EGR system and the overall performance and emissions control of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.