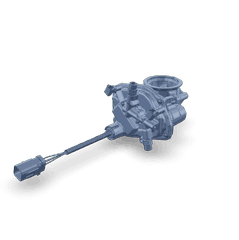

Understanding the Cummins 5333368 Exhaust Throttle Valve

Introduction to Exhaust Throttle Valves

An exhaust throttle valve is a critical component in the exhaust system of heavy-duty trucks and commercial vehicles. It regulates the flow of exhaust gases, which is essential for optimizing engine performance, fuel efficiency, and emissions control 1. This article delves into the specifics of the Cummins 5333368 Exhaust Throttle Valve, its function, and its importance in the operation of commercial trucks.

Basic Concepts of an Exhaust Throttle Valve

An exhaust throttle valve operates by controlling the pressure and flow of exhaust gases exiting the engine. By adjusting the valve’s position, it can either restrict or allow the free flow of exhaust gases. This modulation is crucial for maintaining optimal engine performance across various operating conditions. The valve is typically actuated by mechanical linkages, vacuum actuators, or electronic controls, depending on the engine’s design 2.

Purpose of the Cummins 5333368 Exhaust Throttle Valve

The Cummins 5333368 Exhaust Throttle Valve plays a pivotal role in the engine’s exhaust system. Its primary function is to manage the exhaust backpressure, which directly impacts the engine’s power output and efficiency. By precisely controlling the exhaust flow, the valve helps to:

- Enhance Engine Performance: Ensures that the engine operates within its optimal power band by managing exhaust backpressure.

- Improve Fuel Efficiency: Reduces the energy wasted in the form of exhaust gases, thereby improving the overall fuel economy of the vehicle.

- Control Emissions: Helps in meeting stringent emission standards by optimizing the exhaust gas recirculation (EGR) process 3.

Role in the Operation of a Truck

In the context of a commercial truck, the Cummins 5333368 Exhaust Throttle Valve is integral to the vehicle’s overall performance and efficiency. It ensures that the engine delivers consistent power, whether the truck is cruising on the highway or hauling heavy loads. The valve’s ability to modulate exhaust flow also contributes to the longevity of the engine by reducing wear and tear.

Troubleshooting and Maintenance

Proper maintenance of the Cummins 5333368 Exhaust Throttle Valve is essential to ensure the longevity and efficiency of the engine. Here are some troubleshooting and maintenance tips:

- Regular Inspection: Check the valve for signs of wear, corrosion, or damage. Inspect the actuating mechanism to ensure it operates smoothly.

- Cleaning: Regularly clean the valve and its components to prevent carbon buildup and other deposits that can impede its function.

- Lubrication: Ensure that all moving parts of the valve are adequately lubricated to reduce friction and wear.

- Testing: Use diagnostic tools to test the valve’s operation and ensure it responds correctly to the actuating signals.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of high-performance engines and related components for commercial vehicles. With a legacy of innovation and reliability, Cummins engines are trusted by fleet operators worldwide. The Cummins 5333368 Exhaust Throttle Valve exemplifies the company’s commitment to delivering components that enhance engine performance, efficiency, and durability.

Conclusion

The Cummins 5333368 Exhaust Throttle Valve is a vital component in the exhaust system of commercial trucks. Its role in managing exhaust flow, enhancing engine performance, and controlling emissions cannot be overstated. By understanding the function and maintenance of this valve, engineers, mechanics, and fleet operators can ensure the optimal operation of their vehicles, leading to improved performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.