5398028

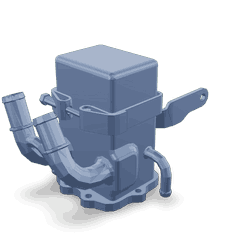

Exhaust Gas Recirculation Cooler

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Gas Recirculation (EGR) Cooler 5398028, manufactured by Cummins, is a component designed to function within the EGR system of modern diesel engines. This part is essential for recirculating exhaust gases back into the intake stream, which aids in reducing emissions and enhancing engine efficiency.

Function and Operation of the EGR Cooler

The EGR Cooler operates by cooling the recirculated exhaust gases before they are reintroduced into the intake stream. This process reduces the temperature of the exhaust gases, thereby lowering the combustion temperature in the engine cylinders. Consequently, the formation of nitrogen oxides (NOx) is minimized, contributing to lower emissions. The cooler achieves this by utilizing a heat exchanger that transfers heat from the exhaust gases to a coolant, typically water or a water-glycol mixture 1.

Purpose of the EGR Cooler in Truck Operations

In commercial truck operations, the EGR Cooler 5398028 contributes to both engine efficiency and emission control. By reducing the temperature of recirculated exhaust gases, the cooler helps maintain optimal combustion conditions, which can lead to improved fuel efficiency. Additionally, it aids in meeting stringent emission standards, ensuring that trucks operate within regulatory limits 2.

Key Features of the Cummins EGR Cooler 5398028

The Cummins EGR Cooler 5398028 is characterized by its robust design and construction. It is built using high-quality materials that ensure durability and efficient heat exchange. The cooler is designed to integrate seamlessly with other engine components, enhancing its functionality within the EGR system. Its cooling efficiency is a notable feature, ensuring that exhaust gases are adequately cooled before re-entering the intake stream 3.

Benefits of Using the EGR Cooler 5398028

Utilizing the EGR Cooler 5398028 offers several advantages. It contributes to improved engine performance by maintaining optimal combustion conditions. Additionally, it plays a role in reducing emissions, particularly NOx, which is beneficial for environmental compliance. The cooler also aids in meeting regulatory standards, ensuring that engines operate within the prescribed emission limits.

Installation and Integration

Proper installation of the EGR Cooler within the truck’s engine system is vital for its effective operation. It is designed to be compatible with various engine models, ensuring a smooth integration process. When installing the cooler, it is important to follow manufacturer guidelines to ensure it functions correctly within the EGR system and alongside other emission control components.

Maintenance and Troubleshooting

Regular maintenance of the EGR Cooler is recommended to ensure its longevity and efficiency. This includes checking for any signs of corrosion, leaks, or blockages within the cooler. Common issues may include reduced cooling efficiency or increased emissions, which can often be addressed by cleaning or replacing the cooler as necessary.

Regulatory Compliance and Environmental Impact

The use of the EGR Cooler helps in meeting emission standards set by regulatory bodies. By reducing NOx emissions, the cooler contributes to lower environmental impact. This is particularly important in the context of increasingly stringent emission regulations aimed at reducing the environmental footprint of diesel engines.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and components, with a history of innovation and commitment to environmental sustainability. The company has been at the forefront of developing technologies that improve engine efficiency and reduce emissions, making it a key player in the industry. Cummins’ dedication to sustainability is evident in its product offerings, including the EGR Cooler 5398028, which exemplifies the company’s approach to balancing performance with environmental responsibility.

Exhaust Gas Recirculation Cooler for Cummins Engines

The Exhaust Gas Recirculation (EGR) Cooler part number 5398028, manufactured by Cummins, is a component in the EGR system of several Cummins engines. This part is designed to cool the exhaust gases before they are recirculated into the engine’s intake system, which helps to reduce the formation of nitrogen oxides (NOx) and improve overall engine efficiency.

Application in Cummins Engines

The EGR Cooler part number 5398028 is compatible with the following Cummins engines:

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

These engines are known for their robust performance and reliability, often used in various industrial and commercial applications. The EGR Cooler is integral to the EGR system in these engines, ensuring that the recirculated exhaust gases are at an optimal temperature, thereby enhancing the engine’s efficiency and reducing emissions.

The integration of the EGR Cooler in these engines is seamless, designed to fit perfectly within the engine’s architecture. Cummins has ensured that the EGR Cooler is engineered to withstand the high temperatures and pressures typical in engine environments, providing a durable and long-lasting solution for maintaining engine performance and compliance with environmental regulations.

Role of Part 5398028 Exhaust Gas Recirculation Cooler in Engine Systems

The Exhaust Gas Recirculation (EGR) Cooler, identified by part number 5398028, is an integral component within the EGR system of modern engine designs. Its primary function is to reduce the temperature of the exhaust gases before they are reintroduced into the intake stream. This cooling process is essential for several reasons:

-

Temperature Regulation: By lowering the temperature of the recirculated exhaust gases, the EGR Cooler helps to prevent overheating within the combustion chamber. This is particularly important during high-load conditions where temperatures can spike.

-

Emission Control: Cooler exhaust gases contribute to lower nitrogen oxide (NOx) emissions. When exhaust gases are recirculated at a reduced temperature, the likelihood of NOx formation during the combustion process is significantly diminished.

-

Improved Efficiency: The EGR Cooler enhances the overall efficiency of the EGR system. By ensuring that the recirculated gases are at an optimal temperature, the system can more effectively dilute the intake charge, leading to smoother combustion and reduced engine knocking.

-

Component Protection: The reduction in temperature of the recirculated exhaust gases also serves to protect other sensitive components within the engine, such as the turbocharger and intercooler, from thermal stress.

In summary, the 5398028 EGR Cooler plays a significant role in maintaining the balance between performance, efficiency, and emission control within the EGR system. Its integration ensures that the recirculated exhaust gases are managed effectively, contributing to the longevity and reliability of the engine system as a whole.

Conclusion

The Exhaust Gas Recirculation Cooler 5398028 by Cummins is a vital component in the EGR system, designed to enhance engine efficiency, reduce emissions, and ensure compliance with environmental regulations. Its robust design, efficient operation, and seamless integration with Cummins engines make it an essential part for maintaining optimal engine performance and environmental responsibility.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.