This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

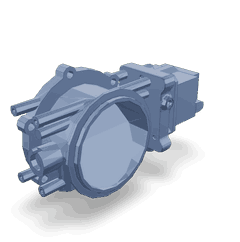

The Exhaust Throttle Valve (Part #5416205) by Cummins is a component designed to regulate exhaust flow in heavy-duty truck engines. Its purpose is to optimize engine performance and emissions by controlling the amount of exhaust gas recirculated back into the engine. This part is significant in enhancing the efficiency and environmental compliance of heavy-duty trucks.

Basic Concepts of Exhaust Throttle Valves

An Exhaust Throttle Valve is a device that manages the flow of exhaust gases within an engine system. It operates by adjusting the opening and closing of a valve in the exhaust system, which allows for precise control over the amount of exhaust gas that is recirculated. This recirculation process helps in reducing emissions and improving fuel efficiency 1.

Role of the Exhaust Throttle Valve in Truck Operation

The Exhaust Throttle Valve plays a role in the overall operation of a heavy-duty truck by regulating exhaust flow, which directly impacts engine performance and emissions. By controlling the recirculation of exhaust gases, the valve helps in maintaining optimal combustion conditions, thereby enhancing engine efficiency and reducing harmful emissions 2.

Key Features of the Cummins Exhaust Throttle Valve

The Cummins Exhaust Throttle Valve is characterized by several key features. Its design incorporates durable materials that ensure longevity and reliability under demanding conditions. Technological advancements in the valve’s construction allow for precise control over exhaust flow, contributing to improved engine performance and emissions management.

Benefits of Using the Cummins Exhaust Throttle Valve

Utilizing the Cummins Exhaust Throttle Valve offers several advantages. These include improved engine efficiency through optimized exhaust flow management, reduced emissions by enhancing the recirculation process, and enhanced overall performance of the truck’s engine. The valve contributes to a more environmentally friendly operation while maintaining high levels of engine performance 3.

Installation and Integration

Installing the Exhaust Throttle Valve involves integrating it into the truck’s exhaust system. This process requires careful attention to ensure proper fitment and functionality. Specific requirements may include aligning the valve with existing exhaust components and ensuring secure mounting to withstand engine vibrations and thermal stresses.

Maintenance and Troubleshooting

Maintaining the Exhaust Throttle Valve is crucial for ensuring its optimal performance and longevity. Regular inspection for signs of wear or damage, cleaning to remove any buildup that may affect operation, and addressing any issues promptly are key maintenance practices. Common problems may include valve sticking or improper sealing, which can be resolved through cleaning or adjustment.

Performance Impact

The Exhaust Throttle Valve affects the truck’s overall performance by influencing fuel efficiency, power output, and emissions levels. Through precise control of exhaust flow, the valve contributes to more efficient combustion, which can lead to improved fuel economy and reduced emissions. Additionally, it plays a role in maintaining engine power by ensuring optimal exhaust gas recirculation.

Regulatory Compliance

The Exhaust Throttle Valve aids trucks in meeting emissions regulations and standards. By managing exhaust flow and enhancing the recirculation process, the valve helps in reducing the levels of harmful emissions released into the environment. This compliance is crucial for operating heavy-duty trucks in regions with stringent environmental regulations.

Compatibility with Cummins Engines

QSK50 CM2350 K108

The Exhaust Throttle Valve (5416205) is engineered to integrate seamlessly with the QSK50 CM2350 K108 engine. This engine is known for its robust design and high power output, making the precise control of exhaust flow essential for maintaining performance and efficiency. The valve’s design ensures that it can withstand the high temperatures and pressures typical of this engine’s operation.

QST30 CM2350 T101

Similarly, the Exhaust Throttle Valve (5416205) is compatible with the QST30 CM2350 T101 engine. This engine variant is also designed for heavy-duty applications, requiring a reliable and durable exhaust throttle valve to manage exhaust gases effectively. The valve’s integration into this engine ensures that it can handle the specific demands of the QST30 model, contributing to the engine’s overall performance and longevity.

Grouping of Engines

Both the QSK50 CM2350 K108 and QST30 CM2350 T101 engines belong to the Cummins CM2350 series, which is known for its versatility and power. The Exhaust Throttle Valve (5416205) is designed to fit these engines due to their shared design principles and operational requirements. This commonality allows for a standardized approach to maintenance and repair, ensuring that the valve can be easily installed and function effectively across both engine models.

Role of Part 5416205 Exhaust Throttle Valve in Engine Systems

The Exhaust Throttle Valve (ETV) part 5416205 is an integral component in modern engine systems, particularly when integrated with a turbocharger. Its primary function is to regulate the flow of exhaust gases, which directly influences the performance and efficiency of the turbocharger.

When the ETV is engaged, it restricts the exhaust flow, creating backpressure. This backpressure enhances the turbocharger’s spool-up time, allowing it to reach optimal operating speeds more quickly. As a result, the turbocharger can deliver compressed air to the engine more efficiently, improving overall engine response and power output.

Additionally, the ETV plays a significant role in reducing turbo lag—the delay between pressing the accelerator and the turbocharger providing boost. By managing exhaust gas flow, the ETV ensures that the turbocharger operates within its optimal range, leading to smoother acceleration and enhanced drivability.

In conjunction with the turbocharger, the ETV also contributes to better fuel efficiency. By optimizing the exhaust flow, the engine can operate more efficiently, reducing the amount of fuel required to achieve desired performance levels. This synergy between the ETV and the turbocharger results in a more responsive and fuel-efficient engine system.

Conclusion

The Exhaust Throttle Valve (Part #5416205) by Cummins is a critical component in the exhaust system of heavy-duty truck engines. It enhances engine performance, improves fuel efficiency, reduces emissions, and ensures regulatory compliance. The valve’s compatibility with specific Cummins engines, such as the QSK50 CM2350 K108 and QST30 CM2350 T101, underscores its importance in maintaining the efficiency and reliability of these powerful engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.