This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

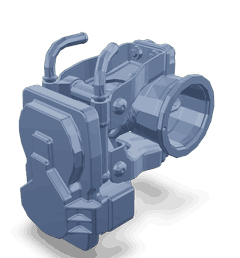

The Exhaust Throttle Valve (Part #5528464) by Cummins is engineered to optimize the performance of commercial trucks. This valve is integral to the engine system, managing exhaust flow to improve engine efficiency and emissions control. Its integration reflects Cummins’ dedication to enhancing vehicle performance and reliability.

Basic Concepts of Exhaust Throttle Valves

An Exhaust Throttle Valve is installed in the exhaust system to regulate the flow of exhaust gases. This regulation maintains optimal pressure within the exhaust system, enhancing engine performance and efficiency. The valve operates in response to signals from the engine’s control unit, allowing precise management of exhaust gas recirculation and backpressure 1.

Purpose and Role in Truck Operation

This Cummins part controls exhaust flow to improve engine performance, manage emissions, and enhance efficiency. By regulating exhaust backpressure, it optimizes the engine’s combustion process, leading to better fuel efficiency and reduced emissions. It also aids in meeting stringent emissions standards, benefiting fleet operators concerned with environmental impact and operational costs 2.

Key Features

The Exhaust Throttle Valve (Part #5528464) features a robust design and high-quality materials for durability and reliability. Its precise actuator mechanism ensures accurate control of the valve’s position, and it is constructed from materials resistant to high temperatures and corrosion, enhancing its longevity in the harsh environment of a truck’s exhaust system 3.

Benefits

Integrating this part into a truck’s engine system offers several benefits, including improved fuel efficiency through optimized combustion, reduced emissions aiding in compliance with environmental regulations, and enhanced engine performance and reliability. These improvements can lead to cost savings through reduced fuel consumption and lower maintenance requirements 4.

Installation and Integration

Proper installation and integration of the Exhaust Throttle Valve (Part #5528464) are crucial for optimal performance. Following manufacturer guidelines ensures the valve is correctly positioned and securely fastened. Integration with the engine’s control system allows the valve to respond accurately to engine conditions, ensuring effective management of exhaust flow.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are essential for the reliable operation of the Exhaust Throttle Valve (Part #5528464). Routine checks should include inspecting the valve for wear or damage, ensuring the actuator mechanism operates smoothly, and verifying integration with the engine’s control system. Troubleshooting may involve checking for obstructions, ensuring proper electrical connections, and addressing any signs of leakage or malfunction.

Cummins Overview

Cummins is renowned for its innovation, quality, and reliability in manufacturing automotive components. The company’s commitment to advancing engine technology has established it as a leader in the field, providing solutions that enhance vehicle performance, efficiency, and sustainability. The Exhaust Throttle Valve (Part #5528464) exemplifies Cummins’ efforts to deliver high-quality, reliable components for commercial truck operation.

Compatibility with Cummins Engines

The Exhaust Throttle Valve, identified by part number 5528464, is designed to manage exhaust flow in various Cummins engines, ensuring optimal performance and efficiency across different engine models.

F2.8 CM2620

The F2.8 CM2620 engine benefits from the precise control provided by the Exhaust Throttle Valve, enhancing overall performance and ensuring operation within desired parameters.

F135B

The F135B engine incorporates the Exhaust Throttle Valve to maintain efficient exhaust flow, optimizing power output and fuel efficiency.

Grouping of Engines

The Exhaust Throttle Valve (part 5528464) is compatible with both the F2.8 CM2620 and F135B engines. Its design ensures a proper fit and function within the exhaust systems of these engines, contributing to their performance and longevity.

Role in Engine Systems

The Exhaust Throttle Valve (ETV), identified by part number 5528464, is integral to modern engine systems, particularly those equipped with turbochargers. Its primary function is to regulate exhaust gas flow, influencing turbocharger performance and efficiency.

When integrated into an engine system with a turbocharger, the ETV works in conjunction with the turbocharger to optimize exhaust gas flow. The turbocharger relies on the momentum of exhaust gases to spin its turbine, which drives the compressor to increase air intake. By modulating exhaust flow, the ETV ensures the turbocharger operates within its optimal range, enhancing power output and fuel efficiency.

The ETV also plays a significant role in reducing turbo lag, which occurs when there is a delay between pressing the accelerator pedal and the turbocharger spooling up to provide boost. The ETV helps mitigate this by controlling exhaust backpressure, allowing the turbocharger to reach operating speed more quickly.

Furthermore, the ETV improves throttle response by precisely managing exhaust flow, allowing for more immediate and consistent power delivery, which is particularly beneficial in high-performance applications.

Conclusion

The Exhaust Throttle Valve (part 5528464) is a sophisticated component that enhances the functionality of turbocharged engine systems. Its ability to fine-tune exhaust gas flow not only boosts turbocharger efficiency but also improves engine responsiveness and reduces turbo lag, making it a valuable addition to modern engine designs.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.