This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

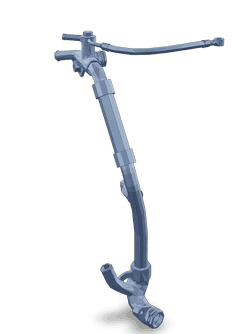

The Cummins 5621761 Belt Tensioner is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine components that rely on belt-driven systems.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying the necessary force to prevent belt slippage, which can lead to inefficient operation and potential damage to the engine components. Maintaining proper belt tension is important for the longevity and performance of the belts and the components they drive 1.

Purpose of the 5621761 Belt Tensioner

The Cummins 5621761 Belt Tensioner is designed to maintain optimal belt tension for various engine components in a truck. It ensures that belts remain properly aligned and tensioned, which is vital for the efficient transfer of power to components such as the alternator, water pump, and air conditioning compressor.

Key Features

The Cummins 5621761 Belt Tensioner is characterized by its robust design and the use of high-quality materials. It features a durable construction that can withstand the demanding conditions of commercial truck operations. The tensioner is engineered with precision to provide consistent tension across the belt’s lifespan, enhancing its performance and reliability 2.

Benefits of Using the 5621761 Belt Tensioner

Utilizing the Cummins 5621761 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that belts operate under the correct tension. This reduces wear on the belts and the components they drive, leading to enhanced reliability and potentially extending the service intervals for belt replacements.

Installation Process

Installing the Cummins 5621761 Belt Tensioner requires following a step-by-step process to ensure proper fitting. The installation may involve specific tools or equipment, and it is important to consider factors such as alignment and tension settings to achieve the correct installation.

Maintenance Tips

Regular maintenance of the Cummins 5621761 Belt Tensioner is recommended to ensure its longevity and effectiveness. This includes periodic inspections for signs of wear or damage, and adhering to manufacturer-recommended inspection intervals. Proper maintenance can help prevent unexpected failures and ensure consistent performance 3.

Troubleshooting Common Issues

Common issues associated with belt tensioners may include noise, slippage, or failure. Troubleshooting these problems involves identifying the symptoms, such as unusual sounds or visible wear, and taking appropriate steps to address the issue, which may include adjustment, repair, or replacement of the tensioner.

Manufacturer Overview - Cummins

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history and commitment to innovation provide a solid foundation for the quality and performance of the 5621761 Belt Tensioner.

Application in ISB Engines

The ISB engine, developed by Chrysler, utilizes the Belt Tensioner part 5621761 to manage the tension of the serpentine belt. This engine is known for its robust performance and reliability, making it a popular choice in various applications. The Belt Tensioner part 5621761 is engineered to fit seamlessly within the ISB engine’s design, providing a reliable and consistent tensioning mechanism.

Compatibility with Other Engines

While the primary focus is on the ISB engine, the Belt Tensioner part 5621761 is also compatible with other engines within the same engine family. This compatibility ensures that the part can be used across multiple models, simplifying maintenance and repair processes. The design of the part is such that it can adapt to the specific requirements of each engine, ensuring optimal performance and durability.

Importance of Proper Tension

Maintaining the correct tension in the serpentine belt is crucial for the efficient operation of the engine. The Belt Tensioner part 5621761 plays a pivotal role in this process by ensuring that the belt remains taut and properly aligned. This not only enhances the performance of the engine but also extends the lifespan of the belt and other related components, reducing the likelihood of unexpected failures and costly repairs.

Installation and Maintenance

Installing the Belt Tensioner part 5621761 is a straightforward process that can be performed by trained technicians. Regular maintenance checks are recommended to ensure that the tensioner is functioning correctly and to replace it if any signs of wear or damage are detected. Proper maintenance of this component is essential for the overall health and performance of the engine.

Conclusion

The Belt Tensioner part 5621761 by Cummins is a vital component in the engine systems of various vehicles, particularly the ISB engine. Its design ensures compatibility with multiple engine models, providing a reliable and efficient solution for maintaining the proper tension of the serpentine belt. Regular maintenance and timely replacement of this part are essential for the longevity and performance of the engine.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.