This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

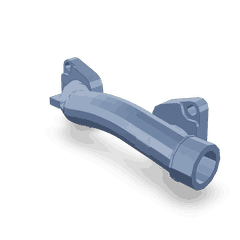

The Exhaust Manifold Assembly, specifically Part #3078322 by Cummins, is a vital component in the engine system of heavy-duty trucks. Cummins, a renowned manufacturer in the automotive industry, produces this assembly with a focus on enhancing engine performance and reliability. This part is integral to the efficient operation of the engine, ensuring that exhaust gases are effectively managed and directed away from the engine 1.

Basic Concepts of Exhaust Manifold Assembly

An Exhaust Manifold Assembly is a component that collects exhaust gases from the engine’s cylinders and channels them into the exhaust system. Its primary functions include reducing backpressure in the engine, improving exhaust flow, and contributing to the overall efficiency of the engine 2. The assembly operates by consolidating the exhaust streams from multiple cylinders into a single path, which then leads to the exhaust pipe and ultimately out of the vehicle.

Purpose of the Exhaust Manifold Assembly

The Exhaust Manifold Assembly by Cummins plays a significant role in the operation of a truck. It is designed to direct exhaust gases away from the engine, which helps in maintaining optimal engine temperature and performance. By efficiently routing exhaust gases, this assembly contributes to the reduction of engine stress and enhances the overall durability and efficiency of the engine 3.

Key Features

The Exhaust Manifold Assembly is constructed from high-quality materials, ensuring durability and resistance to the high temperatures and pressures of the exhaust system. Its design includes precise engineering to ensure a perfect fit with Cummins engines, promoting efficient exhaust flow. Unique characteristics of this assembly may include advanced coatings for heat resistance and specialized welding techniques for enhanced strength 4.

Benefits

The advantages of using the Exhaust Manifold Assembly include improved engine efficiency due to reduced backpressure and enhanced exhaust flow. This assembly also contributes to lower emissions by ensuring that exhaust gases are effectively managed and directed. Additionally, its robust construction and design elements provide enhanced durability, making it a reliable component in the engine system 5.

Installation Process

Proper installation of the Exhaust Manifold Assembly involves several steps. Initially, the old manifold, if present, should be removed carefully to avoid damaging surrounding components. The new assembly should then be aligned with the engine’s exhaust ports and secured using the appropriate fasteners. It is important to ensure that all connections are tight and that the manifold is properly sealed to prevent exhaust leaks. Following the manufacturer’s guidelines for torque specifications is crucial for a secure fit 6.

Common Issues and Troubleshooting

Typical problems associated with Exhaust Manifold Assemblies can include leaks, cracks, and corrosion. These issues may arise due to exposure to high temperatures and pressures over time. Troubleshooting methods involve inspecting the manifold for visible signs of damage, checking for exhaust leaks, and ensuring that all connections are secure. Solutions may range from repairing minor cracks to replacing the assembly if significant damage is detected 7.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and optimal performance of the Exhaust Manifold Assembly. This includes periodic inspections for signs of wear or damage, ensuring that all connections are secure, and addressing any issues promptly. Additionally, keeping the manifold clean and free from excessive buildup can contribute to its efficient operation 8.

Cummins Overview

Cummins is a well-established name in the automotive industry, known for its commitment to quality and innovation in manufacturing engine components. With a rich history of producing reliable and high-performance parts, Cummins has built a reputation for excellence. The company’s dedication to advancing engine technology is evident in its product line, which includes the Exhaust Manifold Assembly, designed to meet the demanding requirements of heavy-duty applications 9.

Compatibility with Cummins Engines

The Exhaust Manifold Assembly, identified by part number 3078322 and manufactured by Cummins, is a critical component in the exhaust system of various Cummins engines. This part is designed to efficiently manage the exhaust gases produced by the engine, ensuring optimal performance and compliance with emission standards.

N14 Celect Plus Engine

The N14 Celect Plus engine is one of the engines that utilizes the Exhaust Manifold Assembly part 3078322. This engine is known for its robust design and reliability, making it a popular choice in heavy-duty applications. The exhaust manifold assembly in this engine plays a pivotal role in directing exhaust gases from the engine’s cylinders to the exhaust system, facilitating the expulsion of these gases and contributing to the overall efficiency of the engine.

The fitment of the Exhaust Manifold Assembly in the N14 Celect Plus engine is meticulously engineered to ensure a seamless integration. This involves precise alignment and secure attachment to the engine block, which is critical for maintaining the integrity of the exhaust system and preventing leaks. The design of the manifold assembly also takes into account the thermal expansion and contraction of the engine components, ensuring durability and longevity under varying operating conditions 10.

Role in Turbocharger Arrangement

The Exhaust Manifold Assembly, identified by part number 3078322, is integral to the efficient operation of the turbocharger arrangement within an engine system. This assembly collects exhaust gases from the engine’s cylinders and directs them towards the turbocharger. The turbocharger, in turn, uses the energy from these exhaust gases to spin a turbine, which compresses the intake air before it enters the engine’s combustion chambers. This process enhances the engine’s power output and efficiency.

The Exhaust Manifold Assembly is designed to withstand high temperatures and pressures, ensuring that the exhaust gases are channeled effectively without loss of energy. Its connection to the turbocharger is meticulously engineered to maintain a sealed system, preventing any escape of exhaust gases that could reduce the efficiency of the turbocharger.

Furthermore, the assembly is crafted to align precisely with the engine’s exhaust ports and the turbocharger’s inlet, facilitating a smooth flow of exhaust gases. This alignment is essential for the turbocharger to operate at optimal efficiency, as any restriction or turbulence in the exhaust flow can diminish the turbocharger’s performance 11.

Conclusion

In summary, the Exhaust Manifold Assembly part 3078322 is a vital component in the N14 Celect Plus engine, contributing to the efficient operation of the exhaust system and overall engine performance. Its role in the turbocharger arrangement further underscores its importance in enhancing engine efficiency and power output.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK95 CM2350 K128M. Bulletin Number 5411388.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK95 CM2350 K128M. Bulletin Number 5411388.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK95 CM2350 K128M. Bulletin Number 5411388.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK95 CM2350 K128M. Bulletin Number 5411388.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK95 CM2350 K128M. Bulletin Number 5411388.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK95 CM2350 K128M. Bulletin Number 5411388.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.