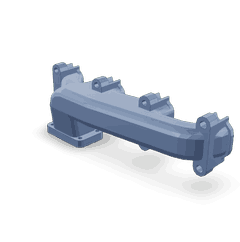

The Cummins 3912600 Exhaust Manifold is a component designed for use in heavy-duty trucks. It plays a role in the engine system by managing the flow of exhaust gases from the engine cylinders to the exhaust system. This part is integral to the efficient operation of the engine, contributing to both performance and emissions management 3.

Basic Concepts of Exhaust Manifolds

An exhaust manifold is a part of the engine system that collects exhaust gases from the individual cylinders and directs them into the exhaust pipe. It functions by consolidating the exhaust flow, which helps in reducing backpressure and improving engine efficiency. The manifold is typically made from cast iron or stainless steel to withstand high temperatures and pressures 2.

Purpose of the Cummins 3912600 Exhaust Manifold

The Cummins 3912600 Exhaust Manifold is specifically engineered to route exhaust gases efficiently from the engine cylinders to the exhaust system. By ensuring a smooth and uninterrupted flow of exhaust, it helps in maintaining engine performance and reducing emissions. This manifold is designed to handle the high temperatures and pressures associated with heavy-duty truck engines, ensuring reliable operation under demanding conditions 3.

Key Features

The Cummins 3912600 Exhaust Manifold features a robust design that includes high-quality materials such as stainless steel, which provides excellent resistance to corrosion and heat. Its design ensures optimal exhaust flow, which contributes to improved engine performance. Additionally, the manifold is engineered to fit precisely with Cummins engines, ensuring a secure and efficient connection 4.

Benefits

The Cummins 3912600 Exhaust Manifold offers several benefits, including improved engine efficiency through better exhaust flow management. It also contributes to reduced emissions by ensuring that exhaust gases are properly routed and managed. The durable construction of the manifold enhances its longevity, providing reliable performance over time 3.

Installation Considerations

Proper installation of the Cummins 3912600 Exhaust Manifold is crucial for ensuring optimal performance. It is important to follow the manufacturer’s guidelines during installation to ensure a secure fit and proper alignment. This may include torque specifications for bolts and ensuring that all gaskets are in good condition. Taking these precautions helps in preventing leaks and ensuring efficient exhaust flow 1.

Maintenance and Troubleshooting

To maintain the Cummins 3912600 Exhaust Manifold, regular inspections are recommended to check for any signs of damage or wear. Common issues may include cracks or leaks, which can be identified through visual inspection or by monitoring engine performance. Addressing these issues promptly can help in maintaining the efficiency and reliability of the engine 3.

Performance Enhancements

The Cummins 3912600 Exhaust Manifold contributes to overall engine performance by ensuring efficient exhaust gas flow. This can lead to improvements in horsepower and torque, as well as enhanced fuel efficiency. The manifold’s design and materials are chosen to withstand the rigors of heavy-duty use, ensuring consistent performance 2.

Compatibility with Cummins Engines

The Cummins Exhaust Manifold part 3912600 is designed to fit seamlessly with several engine models, ensuring optimal performance and efficiency. This part is compatible with the 4B3.9 and B4.5 engines, providing a robust connection between the engine’s cylinders and the exhaust system. Its design allows for efficient exhaust gas flow, which is crucial for maintaining engine performance and reducing emissions.

Additionally, the Exhaust Manifold part 3912600 is also suitable for the QSB3.9 30 CM550 engine. This engine, known for its reliability and power, benefits from the manifold’s ability to handle high-pressure exhaust gases effectively. The manifold’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, durable parts that enhance engine operation 3.

Role in Turbocharger Systems

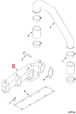

The Cummins 3912600 Exhaust Manifold is an integral component in the efficient operation of various engine systems, particularly when integrated with turbochargers.

In a typical engine setup, the Exhaust Manifold collects exhaust gases from the engine’s cylinders and directs them towards the turbocharger. This arrangement ensures that the turbocharger receives a consistent flow of exhaust gases, which it uses to spin the turbine. The turbine, in turn, drives the compressor, which increases the air pressure entering the engine, enhancing combustion efficiency and power output.

The positioning of the Exhaust Manifold is vital in a Turbocharger Arrangement. It must be strategically placed to minimize exhaust backpressure while maximizing the velocity of the exhaust gases. This is particularly important in engines with multiple turbochargers, where the Exhaust Manifold must efficiently distribute exhaust gases to each turbocharger.

In engines with a specific Turbocharger Location, such as those found in high-performance or diesel engines, the Exhaust Manifold plays a key role in optimizing the turbocharger’s performance. It ensures that the turbocharger operates within its designed parameters, contributing to the engine’s overall efficiency and power delivery.

Furthermore, the design of the Exhaust Manifold must complement the engine’s Manifold and Exhaust system. It should be engineered to handle the high temperatures and pressures of the exhaust gases, while also contributing to the reduction of engine noise and vibrations 4.

Conclusion

The Cummins 3912600 Exhaust Manifold is a critical component in the engine system of heavy-duty trucks. Its role in managing exhaust gas flow contributes to improved engine performance, reduced emissions, and enhanced fuel efficiency. The manifold’s robust design, compatibility with various Cummins engines, and integration with turbocharger systems highlight its importance in maintaining the efficiency and reliability of heavy-duty engines.

References

-

General Information, Bulletin Number 3666143, Operation and Maintenance Manual

↩ -

Automotive Mechatronics, Konrad Reif, Springer Vieweg, 2015

↩ ↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩ ↩ ↩ ↩ -

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.