This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

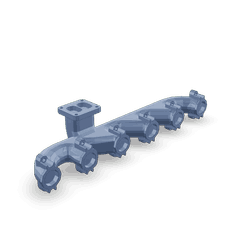

The Cummins 3932185 Exhaust Manifold is a component designed for use in commercial trucks. It plays a role in the engine system by managing the flow of exhaust gases from the engine cylinders to the exhaust system. This part is integral to maintaining efficient engine operation and ensuring that exhaust gases are effectively directed away from the engine 1.

Basic Concepts of Exhaust Manifolds

An exhaust manifold is a part of the engine system that collects exhaust gases from the individual cylinders and channels them into the exhaust pipe. This component is significant for vehicle performance as it helps to reduce backpressure in the engine, which can improve efficiency and power output. The design and material of the exhaust manifold can influence engine performance, durability, and emissions 2.

Purpose of the Cummins 3932185 Exhaust Manifold

The Cummins 3932185 Exhaust Manifold is specifically engineered to handle the high temperatures and pressures associated with commercial truck engines. It plays a role in directing exhaust gases away from the engine, which helps to maintain optimal engine temperature and performance. By efficiently routing exhaust gases, this manifold contributes to the overall efficiency and reliability of the truck’s engine system 3.

Key Features

The Cummins 3932185 Exhaust Manifold is constructed with high-quality materials that are resistant to heat and corrosion. Its design includes precise engineering to ensure a proper fit and function within the engine system. Unique characteristics of this manifold may include enhanced heat dissipation features and a robust construction that supports long-term durability under demanding conditions 4.

Benefits

The Cummins 3932185 Exhaust Manifold offers several advantages. It contributes to improved engine efficiency by ensuring that exhaust gases are effectively managed. This can lead to reduced emissions, as the manifold helps to maintain the engine’s optimal operating conditions. Additionally, the durable construction of this manifold enhances its longevity, providing a reliable component for commercial truck applications 5.

Installation Considerations

Proper installation of the Cummins 3932185 Exhaust Manifold is important to ensure optimal performance and longevity. Installation procedures should follow manufacturer guidelines to avoid issues such as leaks or improper fitment. Specific requirements may include torque specifications for fasteners and the use of appropriate gaskets to seal the manifold to the engine 6.

Troubleshooting and Maintenance

Common issues with exhaust manifolds can include leaks or cracks, which may result from thermal stress or corrosion. Regular inspection and maintenance can help to identify these issues early and prevent more significant problems. Maintenance practices may involve checking for signs of wear or damage and ensuring that all connections are secure and properly sealed 7.

Performance Impact

The Cummins 3932185 Exhaust Manifold can influence various aspects of truck performance, including horsepower, torque, and fuel efficiency. By efficiently managing exhaust gases, this manifold helps to reduce backpressure, which can enhance engine performance. Additionally, its role in maintaining optimal engine temperature can contribute to improved fuel efficiency and overall engine reliability 8.

Environmental Considerations

Exhaust manifolds play a part in the emissions output of vehicles. The design and material of the Cummins 3932185 Exhaust Manifold are factors in meeting emissions regulations. By ensuring efficient exhaust gas flow and reducing the potential for leaks, this manifold supports compliance with environmental standards and contributes to lower emissions from commercial trucks 9.

Compatibility with Specific Engines

6C8.3

The Exhaust Manifold part 3932185 is specifically engineered to fit the 6C8.3 engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The manifold’s design ensures optimal exhaust flow, contributing to the engine’s overall efficiency and power output.

C GAS PLUS CM556

For the C GAS PLUS CM556 engine, the Exhaust Manifold part 3932185 is a critical component. This engine variant is designed for natural gas applications, providing a cleaner and more efficient alternative to diesel. The manifold’s precise fit and construction support the engine’s performance, ensuring that exhaust gases are managed effectively.

C8.3 G

The C8.3 G engine also benefits from the Exhaust Manifold part 3932185. This engine model is part of Cummins’ lineup of gas-powered engines, offering a balance of power and efficiency. The manifold’s design is tailored to the specific needs of the C8.3 G, ensuring that exhaust gases are handled efficiently, contributing to the engine’s overall performance and longevity.

Grouping of Engines

The Exhaust Manifold part 3932185 is designed to fit a range of Cummins engines, including the 6C8.3, C GAS PLUS CM556, and C8.3 G. These engines, while differing in their specific applications and fuel types, share a common requirement for efficient exhaust management. The manifold’s design ensures that it can be used across these models, providing a reliable and effective solution for managing exhaust gases.

Role of Part 3932185 Exhaust Manifold in Engine Systems

The part 3932185 Exhaust Manifold is integral to the efficient operation of engine systems by facilitating the expulsion of exhaust gases from the cylinders to the exhaust system. Once the combustion process is complete within the cylinders, the spent gases need to be expelled to make room for the next intake of air and fuel mixture. This is where the Exhaust Manifold comes into play.

The Exhaust Manifold collects the exhaust gases from all the cylinders and channels them into a single pipe that leads to the catalytic converter. This consolidation is essential for reducing the backpressure in the engine, which can otherwise impede the engine’s performance. By providing a streamlined path for the exhaust gases, the Exhaust Manifold helps maintain optimal engine efficiency.

Furthermore, the Exhaust Manifold is often designed to incorporate features that enhance its functionality. For instance, it may include provisions for mounting oxygen sensors, which are vital for monitoring the exhaust gas composition and ensuring that the engine operates within the desired emissions standards. Additionally, the manifold may be engineered to withstand high temperatures and pressures, ensuring durability and reliability over the engine’s lifespan.

Conclusion

In summary, the part 3932185 Exhaust Manifold plays a significant role in the engine system by efficiently managing the flow of exhaust gases, reducing backpressure, and supporting emissions control through the integration of sensors and other components. Its design and construction are tailored to meet the demanding requirements of commercial truck engines, ensuring optimal performance, durability, and compliance with environmental standards.

-

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4367445, QSK60 CM2350 K116.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4367445, QSK60 CM2350 K116.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4367445, QSK60 CM2350 K116.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.