This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Threaded Plug 4896650 is a component designed for use in heavy-duty truck systems. Its primary role is to seal openings within the truck’s system, thereby preventing fluid leaks and ensuring the system operates efficiently. This part is significant in the context of heavy-duty truck maintenance and operation, as it contributes to the overall integrity and performance of the vehicle 1.

Purpose and Function

The Cummins Threaded Plug 4896650 serves a vital role in sealing various openings within a truck’s system. By effectively sealing these openings, it prevents the leakage of fluids, which could otherwise lead to system inefficiencies or failures. This function is crucial for maintaining the operational integrity of the truck, ensuring that fluids remain within their designated pathways and systems 2.

Key Features

This Cummins part is constructed from materials that offer durability and resistance to corrosion, ensuring long-term performance in demanding environments. Its thread size is designed to provide a secure fit within the specified openings, enhancing its sealing capabilities. The design of the plug also incorporates features that facilitate easy installation and removal, while still maintaining a robust seal 3.

Benefits

Utilizing the Cummins Threaded Plug 4896650 offers several advantages. It contributes to improved system integrity by effectively sealing openings and preventing fluid leaks. This, in turn, reduces the need for frequent maintenance, as the risk of leaks and associated damages is minimized. Additionally, the plug’s durable construction and reliable sealing capabilities enhance the overall performance of the truck, ensuring it operates efficiently under various conditions.

Installation Process

Proper installation of the Cummins Threaded Plug 4896650 is key to ensuring its effectiveness. The process involves using the appropriate tools to clean the opening where the plug will be installed, ensuring it is free from debris and corrosion. The plug should then be screwed into place with the correct torque to achieve a secure fit without over-tightening, which could damage the threads. Following these steps ensures the plug functions as intended, providing a reliable seal.

Common Issues and Troubleshooting

Threaded plugs, including the Cummins Threaded Plug 4896650, may encounter issues such as leaks or corrosion over time. Leaks can often be traced back to improper installation or damage to the plug or the threads it engages with. Corrosion may occur due to exposure to harsh chemicals or environmental conditions. Troubleshooting these issues involves inspecting the plug and its seating for damage, ensuring proper installation techniques are used, and applying protective coatings where necessary to prevent corrosion.

Maintenance Tips

Regular maintenance of the Cummins Threaded Plug 4896650 is recommended to prolong its lifespan and ensure continued reliable performance. This includes periodic inspections for signs of wear, corrosion, or damage, and cleaning the plug and its seating area to remove any buildup that could compromise the seal. Applying a thread sealant during reinstallation can also help maintain the integrity of the seal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines and components for on-highway, off-highway, and stationary applications, demonstrating its versatility and expertise in the automotive industry.

Threaded Plug Part 4896650 in Cummins Engines

The Threaded Plug part 4896650, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to ensure secure and leak-proof sealing in specific engine applications.

ISBE CM800 Engines

In the ISBE CM800 engine series, the Threaded Plug part 4896650 is utilized in several key areas. It is commonly found in the fuel system, where it ensures that fuel lines and connections are tightly sealed, preventing any fuel leaks. Additionally, this plug is used in the coolant system, where it plays a vital role in maintaining the integrity of coolant passages and preventing coolant from escaping.

The threaded design of the plug allows for easy installation and removal, making it a convenient choice for maintenance and repairs. Its robust construction ensures that it can withstand the high pressures and temperatures typical of engine environments, contributing to the overall reliability and performance of the ISBE CM800 engines.

Role of Part 4896650 Threaded Plug in Engine Systems

The part 4896650 Threaded Plug is integral to the proper functioning and maintenance of various engine components. Its application spans across several key areas, ensuring the engine operates efficiently and reliably.

Turbocharger Systems

In turbocharger systems, the 4896650 Threaded Plug is often used to seal off unused ports or passages. This helps maintain the integrity of the turbocharger’s internal environment, preventing leaks that could compromise performance. By ensuring that only the intended airflow paths are active, the plug contributes to optimal turbocharger efficiency and longevity.

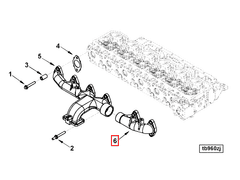

Manifold Applications

Within the manifold, the 4896650 Threaded Plug serves to block off specific pathways that are not in use. This is particularly important in engines with variable configurations or those that have undergone modifications. The plug ensures that air or exhaust flow is directed correctly, enhancing the overall efficiency of the manifold system and reducing the risk of backflow or pressure loss.

Exhaust Systems

In exhaust systems, the 4896650 Threaded Plug is employed to seal off sections of the exhaust manifold or catalytic converter that are not in use. This is especially relevant in engines with multiple exhaust paths or those designed for performance enhancements. By blocking off unnecessary passages, the plug helps maintain consistent exhaust flow, which is vital for reducing emissions and improving engine performance.

Engine Arrangement

The 4896650 Threaded Plug plays a role in the overall engine arrangement by providing a means to seal off components that are not active in a given configuration. This is particularly useful in engines designed for versatility, allowing for easy adaptation to different operational requirements without the need for extensive modifications. The plug ensures that the engine arrangement remains efficient and reliable under varying conditions.

Conclusion

The Cummins Threaded Plug 4896650 is a vital component in heavy-duty truck systems, ensuring the integrity and efficiency of various engine systems. Its durable construction, reliable sealing capabilities, and ease of installation make it an essential part for maintaining the performance and longevity of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.