The 4898113 Exhaust Manifold is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its high-quality engine components. This Cummins part is designed for use in heavy-duty truck engines, where it plays a significant role in the efficient operation of the engine.

Basic Concepts of Exhaust Manifolds

An exhaust manifold is a part of an engine that collects exhaust gases from the cylinders and directs them to the exhaust system. It operates by channeling the high-temperature, high-pressure gases away from the engine, allowing for efficient engine operation. Exhaust manifolds are typically made from materials like cast iron, stainless steel, or a combination of metals, chosen for their durability, heat resistance, and ability to withstand the corrosive nature of exhaust gases 1.

Purpose of the 4898113 Exhaust Manifold

The Exhaust Manifold is integral to the operation of a truck engine. It collects exhaust gases from the engine’s cylinders and directs them towards the exhaust system. This process is vital for maintaining engine efficiency and performance, as it ensures that exhaust gases are expelled effectively, allowing for better engine breathing and overall performance 2.

Key Features of the 4898113 Exhaust Manifold

The Exhaust Manifold is characterized by its robust design and construction, which contribute to its durability and efficiency. It is engineered to provide optimal exhaust gas flow, which is crucial for engine performance. Additionally, its design ensures compatibility with Cummins engines, making it a reliable choice for heavy-duty truck applications 3.

Benefits of Using the 4898113 Exhaust Manifold

Utilizing the Exhaust Manifold in a truck engine can lead to several advantages. These include improved engine performance due to efficient exhaust gas management, enhanced fuel efficiency as a result of better engine breathing, and reduced emissions, contributing to a cleaner operation. These benefits collectively contribute to the overall efficiency and reliability of the truck 4.

Installation Considerations

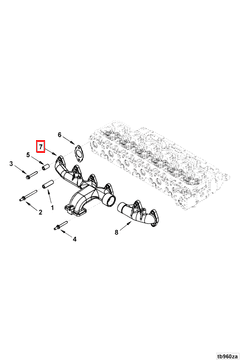

When installing the Exhaust Manifold, it is important to follow guidelines and best practices to ensure optimal performance and longevity. This includes adhering to proper torque specifications for securing the manifold to the engine, selecting the appropriate gasket to ensure a proper seal, and ensuring correct alignment to facilitate efficient exhaust gas flow.

Troubleshooting Common Issues

Exhaust manifolds, including the 4898113, may encounter issues such as leaks, cracks, or corrosion over time. Identifying these problems early is important for maintaining engine performance. Diagnostic techniques may involve visual inspections and listening for unusual sounds during engine operation. Repair procedures can vary depending on the issue but may include replacing gaskets, repairing cracks, or in some cases, replacing the manifold.

Maintenance Tips

To prolong the lifespan of the Exhaust Manifold, routine maintenance practices are recommended. This includes regular inspections for signs of wear or damage, cleaning the manifold to remove any buildup that could impede exhaust flow, and promptly addressing any minor issues to prevent them from developing into major problems.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of producing high-quality engine components. The company is known for its commitment to innovation, quality, and reliability, making it a trusted name among professionals in the heavy-duty truck sector. Cummins’ reputation is built on its dedication to producing components that meet the demanding requirements of heavy-duty applications.

Exhaust Manifold 4898113 Compatibility with Cummins Engines

The Cummins Exhaust Manifold part number 4898113 is designed to fit a variety of Cummins engines, ensuring efficient exhaust gas management across different models. This part is engineered to meet the specific requirements of each engine, providing a reliable and durable solution for exhaust systems.

ISB/ISD6.7 Series

The 4898113 manifold is compatible with the ISB/ISD6.7 CM2150 SN engine, which is known for its robust performance and reliability in heavy-duty applications. This manifold ensures optimal exhaust flow, contributing to the engine’s overall efficiency and power output.

ISBE Series

For the ISBE CM2150 and ISBE CM800 engines, the 4898113 manifold is engineered to fit seamlessly, providing a critical link in the exhaust system. These engines are typically used in on-highway and vocational applications, where durability and performance are paramount.

ISBE4 Series

The ISBE4 CM850 engine also benefits from the 4898113 exhaust manifold. This part is designed to handle the specific exhaust demands of the ISBE4 series, ensuring that the engine operates at peak efficiency.

QSB Series

The 4898113 manifold is also suitable for the QSB5.9 44 CM550 engine, which is widely used in a variety of applications, including agricultural and construction equipment. This manifold ensures that the exhaust system functions efficiently, contributing to the engine’s longevity and performance.

QSB6.7 Series

For the QSB6.7 CM850 (CM2850) engine, the 4898113 manifold is a perfect fit. This engine is known for its versatility and is used in both on-highway and off-highway applications. The manifold ensures that the exhaust system operates smoothly, enhancing the engine’s efficiency and power.

QSB7 Series

Lastly, the 4898113 manifold is compatible with the QSB7 CM2880 B117 engine. This engine is designed for high-performance applications, and the manifold plays a crucial role in managing exhaust gases, ensuring that the engine runs efficiently and reliably.

Role of Part 4898113 Exhaust Manifold in Engine Systems

The Exhaust Manifold is an integral component in the efficient operation of engine systems, particularly when integrated with turbocharger arrangements. Its primary function is to collect exhaust gases from the engine’s cylinders and direct them towards the turbocharger. This process is essential for maximizing the efficiency of the turbocharger, which relies on the kinetic energy from the exhaust gases to spin its turbine and compress the intake air, thereby enhancing engine performance.

In a typical engine setup, the exhaust manifold is connected to the cylinder head, where it gathers exhaust gases from multiple cylinders. These gases then flow through the manifold and into the turbocharger. The turbocharger’s turbine is driven by the high-velocity exhaust, which in turn spins the compressor side of the turbocharger. This compressor increases the pressure of the intake air, allowing more air to enter the engine’s combustion chambers. The increased air mass supports a higher fuel injection rate, leading to more powerful combustion and improved engine output.

The design of the exhaust manifold, such as part 4898113, is optimized to ensure smooth and efficient flow of exhaust gases. This minimizes backpressure, which can otherwise impede engine performance. The manifold’s connection to the turbocharger is engineered to maintain this efficiency, ensuring that the turbine receives a consistent and powerful stream of exhaust gases.

Additionally, the exhaust manifold plays a role in the overall thermal management of the engine. By directing exhaust gases away from the engine block and other sensitive components, it helps in dissipating heat, thereby protecting these parts from excessive temperatures that could lead to damage or reduced efficiency.

Conclusion

In summary, the Exhaust Manifold is a key component in turbocharged engine systems, facilitating the efficient transfer of exhaust gases to the turbocharger, enhancing engine performance, and contributing to effective thermal management. Its robust design and compatibility with various Cummins engines make it a reliable choice for heavy-duty truck applications.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.