This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

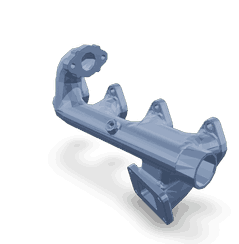

The Cummins 5266045 Exhaust Manifold is a component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by managing the flow of exhaust gases from the engine. This part is integral to maintaining the efficiency and performance of the truck’s engine system.

Basic Concepts of Exhaust Manifolds

An exhaust manifold is a part of the engine system that collects exhaust gases from the cylinders and directs them towards the exhaust system. It operates by channeling the hot gases produced during the combustion process away from the engine. Commonly, exhaust manifolds are manufactured using materials such as cast iron, stainless steel, or in some cases, ceramic-coated metals. These materials are chosen for their ability to withstand high temperatures and corrosive exhaust gases, ensuring durability and efficient performance 1.

Purpose of the Cummins 5266045 Exhaust Manifold

This Cummins part plays a role in the operation of a truck by efficiently routing exhaust gases away from the engine. This process helps in maintaining engine efficiency and performance by ensuring that the exhaust gases are expelled smoothly, which in turn aids in the engine’s overall operation. By managing the flow of these gases, the manifold contributes to the engine’s ability to operate at optimal levels 2.

Key Features

The 5266045 is characterized by several key features that enhance its performance and durability. Its design incorporates materials that can withstand the high temperatures and pressures associated with exhaust gases. Additionally, the manifold is engineered to ensure a secure fit with the engine, promoting efficient operation. Unique attributes may include specific coatings or construction techniques that further enhance its resistance to heat and corrosion.

Benefits

Utilizing this part can lead to several benefits. These include improved engine performance due to efficient exhaust gas management, enhanced durability thanks to its robust construction, and potential cost savings over time as a result of its longevity and reduced need for frequent replacements.

Installation Considerations

When installing this part, it is important to ensure compatibility with the specific engine type. Correct fitting is crucial for the manifold to function as intended, contributing to the engine’s efficiency and performance. Following manufacturer guidelines during installation can help avoid issues and ensure optimal operation.

Maintenance and Troubleshooting

Routine maintenance of this part is key to ensuring its longevity and optimal performance. This may include regular inspections for signs of wear or damage, and cleaning to remove any buildup that could affect its operation. Common issues that may arise include leaks or cracks, which can often be addressed through proper troubleshooting and, if necessary, repairs or replacement.

Performance Enhancements

This part can contribute to overall engine performance enhancements. By efficiently managing exhaust gases, it plays a role in potentially increasing horsepower and torque, thereby improving the truck’s overall performance.

Environmental Impact

The efficient design of this part contributes to reduced emissions and better fuel economy. This aligns with environmental regulations and standards, demonstrating a commitment to minimizing the environmental impact of commercial truck operations 3.

Cummins Overview

Cummins Inc. has a long-standing reputation in the commercial truck industry for its commitment to innovation and quality in manufacturing engine components. The company’s history is marked by a dedication to advancing engine technology, ensuring that its products meet the high demands of commercial applications. Cummins’ focus on quality and performance is evident in its range of engine components, including the Cummins 5266045 Exhaust Manifold.

Cummins Exhaust Manifold Part 5266045 Compatibility

The Exhaust Manifold part number 5266045 is designed to fit seamlessly with several engine models, ensuring optimal performance and efficiency. This part is integral to the exhaust system, facilitating the smooth flow of exhaust gases from the engine cylinders to the exhaust pipe.

ISB CM2150 and ISB6.7 CM2250 Engines

The Exhaust Manifold part 5266045 is specifically engineered to integrate with the ISB CM2150 and ISB6.7 CM2250 engines. These engines are known for their robust performance and reliability, making them popular choices in various applications, from heavy-duty trucks to industrial machinery.

The manifold’s design ensures a precise fit, allowing for efficient heat management and reducing the risk of exhaust leaks. This compatibility is crucial for maintaining the engine’s performance and longevity, as it directly impacts the exhaust system’s efficiency.

Installation and Maintenance

Proper installation of the Exhaust Manifold part 5266045 is essential to ensure that the engine operates at peak efficiency. Regular maintenance checks should be performed to verify that the manifold is securely attached and free from damage or wear. Any signs of leaks or cracks should be addressed promptly to prevent potential engine damage.

By using the Cummins Exhaust Manifold part 5266045, users can expect reliable performance and enhanced exhaust flow, contributing to the overall efficiency and durability of the ISB CM2150 and ISB6.7 CM2250 engines.

Role of Exhaust Manifold in Engine Systems

The exhaust manifold, specifically part 5266045, is integral to the efficient operation of engine systems. It serves as a conduit that collects exhaust gases from the engine’s cylinders and directs them into the exhaust system. This component is designed to withstand high temperatures and pressures, ensuring that exhaust gases are expelled smoothly and efficiently.

In the context of engine systems, the exhaust manifold works in conjunction with several other components to optimize performance and reduce emissions. It interfaces directly with the cylinder head, where it is bolted onto the engine block. This connection allows it to gather exhaust gases from multiple cylinders and channel them into a single pipe, which then leads to the catalytic converter.

The catalytic converter plays a significant role in reducing harmful emissions by converting toxic gases into less harmful substances before they are released into the atmosphere. The efficiency of this conversion process is partly dependent on the smooth and consistent flow of exhaust gases, which the exhaust manifold facilitates.

Furthermore, the exhaust manifold is often connected to the turbocharger in turbocharged engine systems. The turbocharger uses the energy from the exhaust gases to spin a turbine, which in turn drives a compressor that forces more air into the engine’s combustion chambers. This process enhances engine performance by increasing the amount of oxygen available for combustion, thereby allowing for more power output without significantly increasing fuel consumption.

In summary, the exhaust manifold is a key component that ensures the efficient collection and routing of exhaust gases, contributing to the overall performance and emissions control of the engine system. Its integration with components like the cylinder head, catalytic converter, and turbocharger underscores its importance in maintaining both engine efficiency and environmental compliance 4.

Conclusion

The Cummins 5266045 Exhaust Manifold is a critical component in the operation of commercial trucks, ensuring efficient management of exhaust gases and contributing to engine performance and environmental compliance. Its robust design, compatibility with specific engine models, and the benefits it offers make it a valuable part for maintaining and enhancing the efficiency of commercial truck engines.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015

↩ -

Diesel and Gasoline Engines, Richard Viskup, IntechOpen, 2020

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.