This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Outlet Connection, identified by Part #3687351, is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This part is integral to the exhaust system of commercial trucks, facilitating the efficient expulsion of exhaust gases from the engine. Cummins, known for its robust and reliable engine components, ensures that this part meets the demanding requirements of heavy-duty applications 2.

Basic Concepts of Exhaust Outlet Connection

An Exhaust Outlet Connection serves as a conduit within the exhaust system, responsible for directing exhaust gases away from the engine. It interfaces with the exhaust manifold and connects to the exhaust pipe, ensuring a secure and efficient pathway for gases to exit the engine compartment. This connection operates in conjunction with other exhaust system components, such as catalytic converters and mufflers, to manage and reduce emissions while maintaining engine performance 1.

Purpose of the Exhaust Outlet Connection

The Exhaust Outlet Connection plays a significant role in the operation of a truck by providing a direct route for exhaust gases to leave the engine. This part ensures that gases are expelled efficiently, reducing backpressure within the engine and contributing to overall engine performance. By maintaining a clear path for exhaust, it aids in the engine’s ability to breathe, which is vital for optimal operation and fuel efficiency.

Key Features

The Exhaust Outlet Connection is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and high temperatures. The design includes precise fittings and seals to prevent leaks, and it is engineered to withstand the rigors of heavy-duty use. Additionally, the connection may feature unique attributes such as reinforced flanges or specialized coatings to further improve its longevity and efficiency.

Benefits

The advantages of using the Exhaust Outlet Connection include improved engine efficiency due to reduced backpressure, lower emissions as a result of efficient exhaust flow, and enhanced durability that ensures long-term reliability. These benefits contribute to the overall performance and environmental compliance of the vehicle, making it a valuable component for commercial truck operators.

Installation Process

Proper installation of the Exhaust Outlet Connection involves several steps to ensure a secure and efficient connection. Begin by ensuring the engine is cool and the exhaust system is free of debris. Align the connection with the exhaust manifold and exhaust pipe, using the provided gaskets and seals as necessary. Tighten the bolts in a crisscross pattern to ensure even pressure distribution. It is important to check for leaks after installation and make any necessary adjustments to ensure a tight seal.

Common Issues and Troubleshooting

Frequent problems associated with the Exhaust Outlet Connection may include leaks due to worn seals or gaskets, corrosion from exposure to the elements, or damage from physical impact. Troubleshooting methods involve inspecting the connection for signs of wear or damage, replacing any compromised seals or gaskets, and applying protective coatings to prevent corrosion. Regular checks and maintenance can help identify and address issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Exhaust Outlet Connection, regular maintenance practices are recommended. This includes periodic inspections for signs of wear, corrosion, or damage, cleaning the connection to remove any buildup of soot or debris, and applying protective coatings as needed. Additionally, ensuring that all seals and gaskets are in good condition and properly installed will help maintain a secure and efficient exhaust system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and performance in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the needs of heavy-duty applications, ensuring that commercial trucks operate efficiently and reliably 2.

Compatibility with Cummins Engines

The Exhaust Outlet Connection part 3687351, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. Specifically, this part is compatible with the QSX11.9 CM2250 ECF, QSX15 CM2250, and QSX15 CM2250 ECF engines.

For the QSX11.9 CM2250 ECF and QSX15 CM2250 ECF engines, the Exhaust Outlet Connection plays a role in managing the exhaust flow from the turbocharger to the exhaust manifold. This connection ensures that the exhaust gases are efficiently directed, maintaining optimal engine performance and reducing back pressure.

In the case of the QSX15 CM2250 engine, the part serves a similar function, facilitating the connection between the turbocharger and the exhaust manifold. Its design allows for a secure fit, minimizing the risk of leaks and ensuring that the engine operates within its intended parameters.

Overall, the Exhaust Outlet Connection part 3687351 is engineered to provide a reliable and durable solution for these specific Cummins engine models, enhancing their operational efficiency and longevity.

Role of Part 3687351 Exhaust Outlet Connection in Engine Systems

The Exhaust Outlet Connection, identified by part number 3687351, is integral to the efficient operation of various engine systems, particularly those involving emissions control components such as the doser and fluid doser systems.

Integration with Doser Systems

In doser systems, the Exhaust Outlet Connection serves as a vital interface. It ensures a secure and leak-free connection between the doser and the exhaust system. This connection allows the doser to inject precise amounts of Diesel Exhaust Fluid (DEF) into the exhaust stream. The accurate delivery of DEF is essential for the Selective Catalytic Reduction (SCR) process, which converts harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor. The Exhaust Outlet Connection maintains the integrity of this process by providing a consistent and reliable pathway for the doser to interact with the exhaust flow.

Function within Fluid Doser Applications

For fluid doser applications, the Exhaust Outlet Connection plays a similarly important role. It facilitates the controlled introduction of fluid into the exhaust stream, which is critical for maintaining optimal emissions levels. The connection ensures that the fluid is evenly distributed and effectively mixed with the exhaust gases, enhancing the efficiency of the after-treatment system. This results in reduced emissions and compliance with environmental regulations.

Overall System Contribution

Beyond its specific roles in doser and fluid doser systems, the Exhaust Outlet Connection contributes to the overall reliability and performance of the engine’s exhaust system. By providing a sturdy and well-sealed connection point, it helps prevent leaks and maintains the pressure integrity of the exhaust stream. This is particularly important in high-pressure exhaust systems where even minor leaks can lead to significant performance issues and increased emissions.

Conclusion

In summary, the Exhaust Outlet Connection (part 3687351) is a key component in ensuring the effective operation of doser and fluid doser systems within engine applications. Its reliable performance is essential for maintaining efficient emissions control and overall engine efficiency.

SPECIFICATIONS

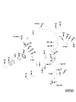

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.