This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

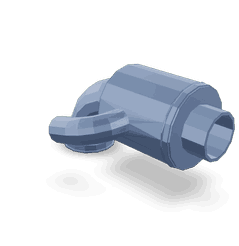

The 4944681 Turbo Oil Drain Tube, manufactured by Cummins, is a component designed for the maintenance and operation of heavy-duty trucks. Cummins, a well-established name in the automotive industry, particularly in the heavy-duty truck sector, produces this part to enhance the efficiency and reliability of truck engines. The Turbo Oil Drain Tube is integral to the turbocharger system, ensuring optimal performance and longevity of the engine.

Basic Concepts of Turbo Oil Drain Tubes

A Turbo Oil Drain Tube is a component within the turbocharger system that facilitates the drainage of oil from the turbocharger. This tube plays a role in maintaining the lubrication system of the turbocharger, which is vital for its operation. By ensuring that excess oil is efficiently drained, the tube contributes to the overall efficiency and longevity of the engine. Proper drainage prevents oil buildup, which can lead to increased friction and wear on turbocharger components 1.

Purpose of the 4944681 Turbo Oil Drain Tube

The 4944681 Turbo Oil Drain Tube serves a specific function within the turbocharger oil system of a truck. Its primary role is to allow for the controlled drainage of oil from the turbocharger, ensuring that the lubrication system operates within optimal parameters. This drainage is crucial for maintaining the performance and reliability of the turbocharger. By facilitating efficient oil drainage, the tube helps in reducing the risk of oil contamination and ensures that the turbocharger components remain well-lubricated, thereby enhancing engine performance 2.

Key Features

The 4944681 Turbo Oil Drain Tube is designed with several key features that enhance its functionality. These include a durable material composition, typically made from high-quality metal or composite materials, ensuring resistance to corrosion and high temperatures. The design elements of the tube are engineered to provide a secure fit within the turbocharger system, minimizing the risk of leaks. Additionally, the tube may feature unique characteristics such as reinforced connections or specialized coatings to further improve its durability and performance 3.

Benefits

Using the 4944681 Turbo Oil Drain Tube offers several benefits. It contributes to improved engine efficiency by ensuring that the turbocharger operates within optimal lubrication parameters. This results in reduced maintenance requirements, as efficient oil drainage minimizes the risk of turbocharger wear and damage. Furthermore, the enhanced durability of the tube means that it can withstand the demanding conditions of heavy-duty truck operation, providing long-term reliability and performance 4.

Installation Process

Installing the 4944681 Turbo Oil Drain Tube requires careful attention to ensure proper fitting. The process involves several steps: first, ensuring that the turbocharger system is clean and free of debris. Next, the old drain tube, if present, should be removed. The new tube should then be positioned within the system, ensuring that all connections are secure. Tools required may include wrenches and possibly a torque wrench to ensure that connections are tightened to the manufacturer’s specifications. It is important to follow the manufacturer’s guidelines to ensure correct fitting and optimal performance.

Maintenance Tips

To ensure the longevity and optimal performance of the 4944681 Turbo Oil Drain Tube, regular maintenance practices are recommended. This includes periodic inspection of the tube for signs of wear, corrosion, or leaks. Cleaning the tube and its connections as part of routine maintenance can prevent buildup and ensure efficient operation. Additionally, following the manufacturer’s recommended inspection intervals and maintenance procedures will help in identifying any potential issues early, ensuring the continued reliability of the turbocharger system.

Troubleshooting Common Issues

Common problems associated with Turbo Oil Drain Tubes may include leaks, blockages, or corrosion. To address these issues, it is important to first identify the source of the problem. For leaks, checking the connections and seals for damage or wear is crucial. Blockages may require cleaning or, in some cases, replacement of the tube. Corrosion can be addressed through cleaning and, if necessary, applying a protective coating. Regular maintenance and inspections can help in preventing these issues and ensuring the efficient operation of the turbocharger system.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a strong reputation in the heavy-duty truck sector. Founded in 1919, Cummins has a long history of innovation and quality, producing a wide range of engines and components designed for durability and performance. The company’s product range includes engines, filtration systems, and aftermarket parts, all engineered to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to quality and reliability has established it as a trusted name in the industry.

Turbo Oil Drain Tube (Part 4944681) Compatibility with Cummins Engines

The Turbo Oil Drain Tube, identified by the part number 4944681, is a critical component in the maintenance and operation of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and without contamination.

QSB6.7 M CM2250

The QSB6.7 M CM2250 engine is one of the models that benefit from the Turbo Oil Drain Tube. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The Turbo Oil Drain Tube ensures that any excess oil is effectively removed from the turbocharger, preventing oil from entering the turbine and potentially causing damage.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine is another model that utilizes the Turbo Oil Drain Tube. This engine is designed for high-performance applications, providing significant power and efficiency. The Turbo Oil Drain Tube plays a crucial role in maintaining the integrity of the turbocharger by ensuring that oil is properly drained, which helps in extending the life of the turbocharger and maintaining optimal engine performance.

By using the Turbo Oil Drain Tube in these engines, maintenance personnel can ensure that the turbocharger operates smoothly and efficiently, reducing the risk of oil-related issues and extending the overall lifespan of the engine components.

Role of Part 4944681 Turbo Oil Drain Tube in Engine Systems

The 4944681 Turbo Oil Drain Tube is an essential component in the efficient operation of turbocharged engine systems. It is strategically positioned to facilitate the seamless flow of oil from the turbocharger to the oil pan, ensuring that the lubrication system remains effective under high-stress conditions.

Integration with Key Components

Connection to Exhaust Outlet

The Turbo Oil Drain Tube connects directly to the exhaust outlet, allowing for the efficient drainage of oil that may accumulate in the turbocharger. This connection is vital for maintaining the turbocharger’s performance and longevity. By ensuring a consistent flow of oil back to the sump, the tube helps prevent oil buildup, which could otherwise lead to increased friction and potential damage to the turbocharger bearings.

Interface with Exhaust Riser Kit

When integrated with an exhaust riser kit, the Turbo Oil Drain Tube plays a significant role in enhancing the overall exhaust system’s efficiency. The riser kit is designed to improve exhaust flow and reduce backpressure, which in turn enhances engine performance. The Turbo Oil Drain Tube complements this by ensuring that any oil that has been aerosolized and carried through the exhaust system is effectively returned to the oil pan. This not only maintains the lubrication system’s integrity but also helps in reducing oil consumption and preserving the cleanliness of the exhaust components.

Operational Synergy

The Turbo Oil Drain Tube works in harmony with these components to ensure that the turbocharged engine operates smoothly. By facilitating the return of oil to the sump, it supports the turbocharger’s lubrication needs, which is especially important during high-RPM operations where the demand for efficient oil circulation is at its peak. This synergy between the Turbo Oil Drain Tube, exhaust outlet, and exhaust riser kit contributes to the engine’s reliability and performance, making it a key element in the maintenance and optimization of turbocharged engine systems.

Conclusion

The 4944681 Turbo Oil Drain Tube is a vital component in the maintenance and operation of heavy-duty truck engines, particularly those manufactured by Cummins. Its role in facilitating efficient oil drainage from the turbocharger ensures optimal lubrication, reduces maintenance requirements, and enhances engine performance and longevity. Proper installation, regular maintenance, and timely troubleshooting of common issues are essential for maximizing the benefits of this Cummins part. By understanding its key features, benefits, and integration with other engine components, maintenance personnel can ensure the continued reliability and efficiency of turbocharged engine systems.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩ -

Wharton, A. J. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩ -

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.