This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3002223 Fan Pulley is a critical component for commercial trucks, essential for the engine cooling system. It ensures the cooling fan operates efficiently, maintaining optimal engine temperature and enhancing engine performance 1.

Basic Concepts of a Fan Pulley

A fan pulley is a mechanical device that connects the engine’s crankshaft to the cooling fan via a belt. It transfers rotational energy from the engine to the fan, enabling it to draw air through the radiator to cool the engine. This interaction with components like the fan blade and engine belt ensures the cooling system operates smoothly 2.

Purpose of the 3002223 Fan Pulley

This part is integral to the truck’s engine cooling system, maintaining optimal engine temperature by ensuring the cooling fan operates efficiently. This prevents engine overheating and contributes to the engine’s overall performance and longevity 3.

Key Features

The Cummins 3002223 Fan Pulley is constructed with high-quality materials for durability and reliable performance. Its robust build and precise engineering enhance its ability to withstand the rigors of commercial truck operation, contributing to its effectiveness in the cooling system.

Benefits

This Cummins part offers several advantages, including improved engine cooling efficiency, which helps maintain engine temperature within optimal ranges. It also reduces wear on associated components by ensuring smooth operation of the cooling fan, resulting in enhanced overall engine performance and reliability.

Installation Process

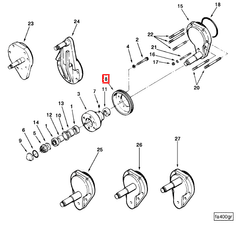

Installing the 3002223 Fan Pulley requires careful attention to detail. The process involves preparing the engine compartment, aligning the pulley with the crankshaft, and securing it in place with the appropriate tools. Proper alignment and tensioning of the engine belt are essential for the pulley’s effective operation.

Troubleshooting Common Issues

Common issues with fan pulleys include noise, vibration, or overheating, often due to misalignment, worn bearings, or a loose belt. Diagnostic steps may include inspecting the pulley and belt for wear, ensuring proper alignment, and tightening or replacing components as necessary.

Maintenance Tips

Regular maintenance practices can prolong the lifespan of the 3002223 Fan Pulley. This includes periodic inspection for signs of wear or damage, cleaning the pulley and surrounding components to remove debris, and ensuring the engine belt is properly tensioned. Replacement should be considered if significant wear or damage is detected.

Compatibility and Application

The 3002223 Fan Pulley is designed for specific types of engines and truck models. It is important to verify compatibility with the vehicle’s make and model to ensure proper fit and function. Application notes may include specific installation instructions or considerations for optimal performance.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for reliability and performance. The company’s history of excellence underscores its dedication to meeting the needs of commercial truck operators.

Fan Pulley Part 3002223 Compatibility with Cummins Engines

The Fan Pulley part number 3002223, manufactured by Cummins, is designed to integrate seamlessly with several of their engine models. This part is essential for the proper functioning of the engine’s cooling system, ensuring that the fan operates efficiently to maintain optimal engine temperature.

K19 Engine

The K19 engine, known for its robust performance and reliability, utilizes the Fan Pulley part 3002223 to drive the cooling fan. This pulley is engineered to fit precisely with the K19 engine’s design, ensuring a secure and efficient connection that minimizes wear and maximizes performance.

QSK19 Engine

Similarly, the QSK19 engine incorporates the Fan Pulley part 3002223 as a critical component of its cooling system. This engine, favored for its versatility and power, relies on the precise fit and durability of the Fan Pulley to maintain consistent cooling performance under various operating conditions.

CM500 Engine

The CM500 engine, another robust model in Cummins’ lineup, also employs the Fan Pulley part 3002223. This part is designed to integrate with the CM500’s specific design parameters, ensuring that the cooling fan operates smoothly and effectively, contributing to the engine’s overall reliability and longevity.

Grouping of Engines

The Fan Pulley part 3002223 is compatible with the K19, QSK19, and CM500 engines, showcasing Cummins’ commitment to standardization and interchangeability across their engine models. This compatibility allows for easier maintenance and repair, as technicians can use the same part across multiple engine types, streamlining the process and reducing downtime.

Role of Part 3002223 Fan Pulley in Engine Systems

The part 3002223 Fan Pulley is an integral component in the orchestration of various engine systems, ensuring efficient operation and performance.

Integration with the Drive System

The Fan Pulley interfaces directly with the engine’s drive system. It is responsible for transmitting rotational force from the engine to the fan, enabling the fan to operate. This transmission of power is essential for maintaining the correct airflow over the engine’s cooling components, thus playing a significant role in the engine’s thermal management.

Function within the Fan Drive Arrangement

In the fan drive arrangement, the Fan Pulley works in conjunction with the fan clutch or viscous drive. This arrangement allows for variable fan speed, which is beneficial for optimizing engine cooling under different operating conditions. The Fan Pulley’s design ensures smooth and efficient power transfer, which is vital for the effective functioning of the fan drive system.

Connection to the Fan Hub

The Fan Pulley is mounted onto the fan hub, which is the central point for the fan blades. This mounting ensures that the fan rotates in sync with the engine’s RPM, providing consistent airflow. The precise fitting of the Fan Pulley to the fan hub is essential for minimizing vibrations and ensuring longevity of both components.

Interaction with the Mounting System

The mounting of the Fan Pulley is a critical aspect of its function. It must be securely attached to the engine to withstand the forces exerted during operation. The mounting brackets and bolts must be of adequate strength and properly torqued to ensure the Fan Pulley remains in place and functions correctly throughout the engine’s operational life.

Relationship with the Alternator

Although the alternator is driven by a separate pulley, the operation of the Fan Pulley can indirectly affect the alternator’s performance. The Fan Pulley contributes to maintaining optimal engine temperature, which in turn ensures that the alternator operates within its specified temperature range. This is important for the alternator’s efficiency and lifespan, as excessive heat can lead to decreased performance and potential failure.

Conclusion

The part 3002223 Fan Pulley is a key component that facilitates the interaction between the engine’s drive system and the cooling system. Its proper function is essential for the efficient operation of the fan, which is paramount for engine cooling and, by extension, the overall performance and reliability of the engine system.

-

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.