This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

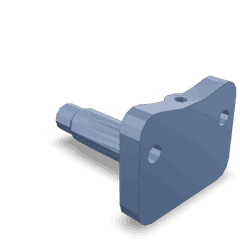

The Fan Hub Shaft 3056365, manufactured by Cummins, is a component integral to the cooling system of heavy-duty trucks. Cummins, a well-established name in the automotive industry, is recognized for its commitment to quality and innovation in manufacturing automotive components. This part is designed to enhance the efficiency and reliability of the truck’s cooling system, ensuring optimal engine performance under various operating conditions.

Basic Concepts and Functionality

The operation of the Fan Hub Shaft in a truck’s cooling system is based on fundamental principles of mechanical engineering. The Fan Hub Shaft serves as the central pivot point for the fan blades, which are responsible for drawing air through the radiator to cool the engine. It connects to the engine via a drive mechanism, typically a belt or a direct drive system, allowing it to rotate in sync with the engine’s operation. This rotation facilitates the movement of air across the radiator, playing a role in dissipating heat generated by the engine 1.

Purpose of the Fan Hub Shaft 3056365

This Cummins part plays a role in the operation of a truck by ensuring efficient air circulation through the radiator. This component is instrumental in maintaining optimal engine temperature, which is crucial for the engine’s longevity and performance. By facilitating effective heat exchange, the Fan Hub Shaft contributes to the overall efficiency of the truck’s cooling system, allowing the engine to operate within its designed temperature range under various load conditions 2.

Key Features

The Fan Hub Shaft 3056365 is characterized by several key features that enhance its performance and durability. Its design incorporates high-strength materials, ensuring resilience under the demanding conditions typical of heavy-duty truck operations. The shaft is engineered for precision fitment, reducing the likelihood of misalignment and associated wear. Additionally, its construction may include features such as corrosion-resistant coatings, which contribute to its longevity in harsh operating environments.

Benefits

Utilizing the Fan Hub Shaft 3056365 in heavy-duty trucks offers several advantages. These include improved engine efficiency due to effective cooling, reduced wear and tear on engine components as a result of maintaining optimal operating temperatures, and enhanced cooling performance under high-load conditions. The robust design of the Fan Hub Shaft also contributes to the overall reliability of the truck’s cooling system, minimizing the risk of unexpected failures.

Installation Process

Installing the Fan Hub Shaft 3056365 requires adherence to a specific procedure to ensure proper fitment and operation. The process involves disconnecting the drive mechanism, removing the old fan hub shaft, and installing the new component in its place. Tools required may include wrenches and alignment tools to ensure the shaft is correctly positioned. Safety precautions, such as ensuring the engine is cool before beginning work and wearing appropriate personal protective equipment, should be observed throughout the installation process.

Troubleshooting Common Issues

Common issues associated with the Fan Hub Shaft 3056365 may include misalignment, wear, or failure of the shaft or its bearings. Troubleshooting steps involve inspecting the shaft for signs of damage or wear, checking the alignment of the fan blades, and ensuring the drive mechanism is functioning correctly. Addressing these issues promptly can prevent more severe problems, such as engine overheating or failure of the cooling system.

Maintenance Tips

Regular maintenance of the Fan Hub Shaft 3056365 is key to ensuring its longevity and efficient operation. This includes periodic inspection for signs of wear or damage, cleaning the shaft and surrounding components to remove debris that could affect performance, and lubricating moving parts as necessary. Adhering to recommended inspection intervals and maintenance procedures can significantly extend the service life of the Fan Hub Shaft and the overall cooling system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s commitment to excellence is evident in its extensive product range, which includes engines, powertrains, and aftermarket parts designed to meet the demanding requirements of various applications, from heavy-duty trucks to industrial equipment.

Compatibility with Cummins Engines

The Fan Hub Shaft part number 3056365 is compatible with various Cummins engine models, including the N14 CELECT, N14 CELECT PLUS, N14 MECHANICAL, and NH/NT 855 engines. This part is essential for the proper functioning of the engine’s cooling system, ensuring that the fan operates smoothly and efficiently.

Understanding the Integration of Part 3056365 Fan Hub Shaft in Engine Systems

The Fan Hub Shaft 3056365 is a pivotal component in the orchestration of various engine cooling systems. Its role is to facilitate the efficient operation of the fan and fan hub assembly, ensuring optimal airflow across the engine’s radiator.

Drive Mechanism

The Fan Hub Shaft interfaces directly with the engine’s drive mechanism. This connection is essential for transferring rotational force from the engine to the fan. The efficiency of this transfer is paramount for maintaining the correct fan speed, which is directly related to the cooling needs of the engine.

Fan and Fan (Painted) Hub

Once the drive mechanism imparts motion to the Fan Hub Shaft, the shaft then rotates the fan and fan (painted) hub. The fan, often painted for aesthetic or protective purposes, is responsible for drawing air through the radiator. The fan hub, to which the fan blades are attached, ensures that the fan operates at the correct angle and speed to maximize airflow.

Fan Arrangement and Fan Drive Arrangement

The configuration of the fan arrangement—whether it’s a single fan or a dual fan setup—is influenced by the Fan Hub Shaft. Similarly, the fan drive arrangement, which could be a belt-driven or clutch-driven system, relies on the shaft to transmit power efficiently from the engine to the fan.

Fan Drive Ratio 1 to 1

In systems where a 1 to 1 fan drive ratio is employed, the Fan Hub Shaft plays a role in maintaining this precise ratio. This ensures that the fan rotates at the same speed as the engine’s crankshaft, providing consistent cooling performance across varying engine speeds.

Fan Hub and Fan Hub Arrangement

The Fan Hub Shaft is integral to the fan hub and its arrangement. It supports the fan hub, allowing it to rotate freely while withstanding the forces exerted by the fan blades. The arrangement of the fan hub—whether it’s a fixed or variable pitch design—is designed to optimize airflow and cooling efficiency.

Hub Fan

In some engine systems, the configuration is such that the fan is directly attached to the hub, forming a hub fan assembly. The Fan Hub Shaft in this scenario acts as the central pivot point, ensuring that the hub fan operates smoothly and effectively to cool the engine.

Conclusion

In summary, the Fan Hub Shaft 3056365 is a fundamental component that connects and enables the efficient operation of the fan, fan hub, and related assemblies within the engine’s cooling system. Its proper function is essential for the maintenance of optimal engine operating temperatures. Regular maintenance and prompt troubleshooting of common issues can significantly extend the service life of this part and enhance the overall efficiency of the truck’s cooling system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.