This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

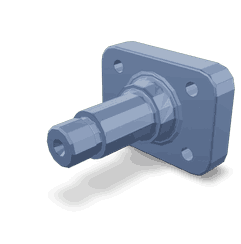

The 3095226 Fan Spindle, manufactured by Cummins, is a critical component for heavy-duty truck engines. Cummins, a prominent figure in the automotive and heavy-duty truck sector, offers a variety of parts and systems that enhance engine efficiency and reliability. This part is essential in the context of heavy-duty truck engines due to its role in the engine cooling system 1.

Basic Concepts of a Fan Spindle

A fan spindle is a mechanical component that supports and rotates the cooling fan within an engine’s cooling system. Its primary function is to facilitate the movement of air across the radiator, aiding in the dissipation of heat generated by the engine. In the context of a truck engine, the fan spindle operates by being driven either directly by the engine or through a clutch mechanism that allows it to engage and disengage based on the engine’s cooling needs 2.

Purpose of the 3095226 Fan Spindle

The 3095226 Fan Spindle ensures the engine maintains an optimal temperature by supporting the cooling fan, which increases airflow through the radiator when the engine temperature rises. This function is vital for efficient engine performance, as it prevents overheating and potential engine damage 3.

Key Features

This Cummins part is characterized by several primary features that enhance its functionality. These include a robust material composition designed to withstand the high stresses and temperatures of a truck engine environment. Its construction is engineered for durability, with precision-machined components that ensure smooth operation. Unique design aspects may include features that reduce noise and vibration, contributing to the overall efficiency and longevity of the component 4.

Benefits

The 3095226 Fan Spindle offers several advantages, including improved engine cooling efficiency. Its durable construction ensures reliability under various operating conditions, contributing to the overall performance and longevity of the engine. The spindle’s design also aims to reduce maintenance requirements, providing value to truck operators.

Installation Process

Installing the Fan Spindle requires attention to detail to ensure optimal performance and longevity. The process involves securing the spindle to the engine and connecting it to the cooling fan. It is important to follow manufacturer guidelines for torque specifications and alignment to prevent issues such as vibration or reduced efficiency. Proper lubrication and inspection of all connections are also critical steps in the installation process.

Maintenance Tips

To keep the 3095226 in optimal condition, routine maintenance practices are recommended. This includes regular inspection intervals to check for wear or damage, ensuring all connections are secure, and applying lubrication as specified by the manufacturer. Cleaning the spindle and surrounding components can also help maintain efficiency and prevent buildup that could affect performance.

Troubleshooting Common Issues

Typical problems associated with fan spindles, such as noise, vibration, or reduced cooling efficiency, can often be traced back to installation issues, wear and tear, or lack of maintenance. Diagnostic steps may involve inspecting the spindle for damage, checking alignment and connections, and ensuring proper lubrication. Addressing these issues promptly can help maintain the efficiency and reliability of the engine cooling system.

Compatibility and Application

The 3095226 is designed for use in specific types of engines and truck models. Its application is guided by compatibility with the engine’s cooling system requirements and the truck’s operational environment. Understanding these compatibility factors is important for ensuring the spindle performs as intended within the engine system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability and performance in the automotive and heavy-duty truck industry. This background provides context for the quality and reliability associated with the 3095226 Fan Spindle.

Compatibility with Cummins Engines

This part is designed to fit a variety of Cummins engine models. It is crucial for the proper functioning of the engine’s cooling system, ensuring that the fan operates smoothly and efficiently.

G855 Series

The Fan Spindle is compatible with the G855 engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications.

G855 CM558 and GTA855 CM558 (CM2358)

Both the G855 CM558 and GTA855 CM558 (CM2358) engines utilize the Fan Spindle. These engines are part of the Cummins G series and are recognized for their durability and efficiency in various industrial applications.

G101

The G101 engine is another model that is compatible with the Fan Spindle. This engine is designed for applications requiring high power output and reliability.

N14 Series

The Fan Spindle fits the N14 CELECT PLUS and N14 G engines. These engines are part of the Cummins N series, known for their versatility and performance in a range of applications.

NH/NT 855

The NH/NT 855 engine is also compatible with the Fan Spindle. This engine is designed for heavy-duty applications, providing robust performance and reliability.

QSN14 CM876 N103

The QSN14 CM876 N103 engine is another model that uses the Fan Spindle. This engine is part of the Cummins QSN series, known for its high power output and efficiency in demanding conditions.

Understanding the Role of Part 3095226 Fan Spindle in Engine Systems

The 3095226 Fan Spindle is an integral component within the engine system, facilitating the seamless operation of several key elements. Its primary function is to connect and enable the rotation of the fan, which is essential for maintaining optimal engine temperature.

Interaction with the Drive System

The Fan Spindle interfaces directly with the drive system. This connection ensures that rotational force is efficiently transferred from the engine to the fan. The drive system, typically comprising a belt or chain mechanism, relies on the spindle to maintain alignment and smooth operation. This interaction is fundamental for the consistent performance of the cooling system.

Integration with the Fan

At the heart of the cooling mechanism, the Fan Spindle is responsible for the rotational movement of the fan. As the spindle rotates, it drives the fan blades, which in turn move air across the radiator. This airflow is vital for dissipating heat generated by the engine, ensuring that the engine operates within safe temperature ranges.

Role in the Fan Drive Assembly

The Fan Spindle is a key element within the Fan Drive Assembly. This assembly often includes a clutch mechanism that allows the fan to operate only when necessary, reducing parasitic losses and improving fuel efficiency. The spindle’s precise fit and robust design are essential for the reliable function of this assembly, ensuring that the fan engages and disengages smoothly as required.

Connection to the Fan Hub

Finally, the Fan Spindle connects to the Fan Hub, which is the central point of attachment for the fan blades. The hub must be securely fastened to the spindle to withstand the forces generated during operation. This connection ensures that the fan blades are positioned correctly and can rotate freely, maximizing airflow and cooling efficiency.

Conclusion

In summary, the 3095226 Fan Spindle plays a significant role in the engine’s cooling system by facilitating the efficient transfer of rotational force from the drive system to the fan, ensuring that the engine remains cool under various operating conditions. Its robust design, compatibility with a range of Cummins engines, and the critical role it plays in maintaining engine temperature underscore its importance in heavy-duty truck applications.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ -

Bosch, R. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.