3910132

Fan Pilot Spacer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

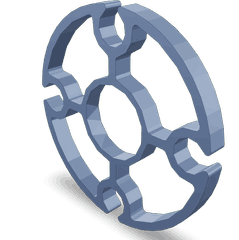

The Fan Pilot Spacer 3910132 is a component designed by Cummins for use in the cooling systems of heavy-duty trucks. Its primary role is to facilitate the proper operation of the cooling fan, which is vital for maintaining optimal engine temperature under various operating conditions.

Purpose and Function

The Fan Pilot Spacer plays a role in the engine cooling system by ensuring the correct positioning and operation of the cooling fan. It helps maintain the necessary clearance between the fan and other components, allowing the fan to operate efficiently without interference. This spacing is crucial for the fan to draw air effectively through the radiator, thereby aiding in the dissipation of heat from the engine coolant. Proper fan operation is key to preventing engine overheating, which can lead to reduced performance and potential damage 1.

Key Features

The Fan Pilot Spacer 3910132 is constructed from durable materials that can withstand the high temperatures and mechanical stresses present in heavy-duty truck engines. Its design includes precise dimensions to ensure accurate fan alignment and spacing. The spacer is engineered to be resistant to corrosion and wear, enhancing its longevity and reliability in demanding environments 2.

Benefits

Utilizing the Fan Pilot Spacer 3910132 offers several advantages. It contributes to improved engine efficiency by ensuring that the cooling fan operates within its designed parameters. This results in more effective heat management, which can lead to enhanced overall performance of the truck. Additionally, by maintaining proper fan clearance, the spacer helps reduce wear on cooling system components, potentially lowering maintenance costs and increasing the lifespan of the cooling system 3.

Installation Process

Installing the Fan Pilot Spacer requires careful attention to detail to ensure optimal function. The process involves aligning the spacer correctly between the fan and the engine components, followed by securing it in place according to the manufacturer’s specifications. Proper installation is vital for the spacer to perform its intended function effectively.

Common Issues and Troubleshooting

Typical problems associated with the Fan Pilot Spacer may include wear, misalignment, or failure due to extreme conditions. Troubleshooting these issues involves inspecting the spacer for signs of damage or improper installation. Solutions may range from simple re-alignment or cleaning to replacement of the spacer if it is found to be damaged or worn beyond its serviceable life.

Maintenance Tips

Regular maintenance of the Fan Pilot Spacer is recommended to prolong its lifespan and ensure continued efficient operation. This includes periodic inspection for signs of wear or damage, cleaning to remove any debris that may accumulate, and ensuring that it remains properly aligned and secured. Adhering to these maintenance practices can help prevent unexpected failures and maintain the efficiency of the cooling system.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on engine components underscore its dedication to enhancing the performance and reliability of heavy-duty vehicles.

Compatibility with Cummins Engines

The Fan Pilot Spacer part number 3910132, manufactured by Cummins, is designed to fit various Cummins engine models. This part ensures proper alignment and spacing between the fan and the engine’s pilot, contributing to the efficient operation of the cooling system. Below is a detailed breakdown of the engines with which this part is compatible:

4B Series Engines

- 4B3.9

6B Series Engines

- 6B5.9

6C Series Engines

- 6C8.3

B Series Engines

- B4.5

- B5.9 G

C Series Engines

- C8.3 G

F Series Engines

- F3.8 CM2350 F128C

ISB Series Engines

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL9 CM2150 SN

- ISL9 CM2250

QSB Series Engines

- QSB3.9 30 CM550

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB5.9 30 CM550

- QSB5.9 44 CM550

This part is engineered to ensure a precise fit, maintaining the integrity of the cooling system across these diverse engine models.

Role of Fan Pilot Spacer in Engine Systems

The Fan Pilot Spacer 3910132 is an integral component in the assembly and operation of various engine systems. Its primary function is to provide the necessary spacing and alignment between the fan and the pilot, ensuring optimal performance and efficiency of the engine.

Integration with Engine Components

-

Fan Assembly: The Fan Pilot Spacer is positioned between the fan and the pilot, maintaining the correct distance and alignment. This ensures that the fan operates smoothly without unnecessary vibrations or wear.

-

Pilot Bearing: By providing the appropriate spacing, the spacer allows the pilot bearing to function effectively. The pilot bearing relies on precise alignment to reduce friction and wear, contributing to the longevity of the engine.

-

Thrust Washer: The spacer interacts with the thrust washer to manage axial loads. Proper spacing ensures that the thrust washer can distribute loads evenly, preventing premature failure.

-

Compressor Housing: The spacer plays a role in the overall stability of the compressor housing. By ensuring that the fan and pilot are correctly aligned, it helps maintain the structural integrity of the compressor housing under operational stresses.

-

Rotor Assembly: In the rotor assembly, the Fan Pilot Spacer helps in maintaining the balance and alignment of rotating components. This is essential for smooth operation and to prevent undue stress on the rotor bearings.

-

Sealing Components: The spacer indirectly supports the function of sealing components by ensuring that all rotating parts are aligned correctly. This alignment is vital for the seals to operate effectively, preventing leaks and maintaining engine efficiency.

-

Lubricating Systems: Proper spacing and alignment facilitated by the spacer ensure that lubricating systems can deliver oil to the necessary components without obstruction. This is important for reducing friction and wear in moving parts.

-

Cooling Systems: The spacer contributes to the efficient operation of cooling systems by ensuring that all components are aligned correctly. This alignment allows for optimal airflow and heat dissipation, crucial for engine performance.

Conclusion

In summary, the Fan Pilot Spacer 3910132 is a key component that ensures the precise alignment and spacing of various engine parts, contributing to the smooth and efficient operation of the engine system. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.