This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

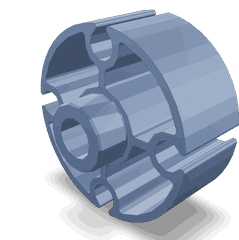

The Fan Pilot Spacer 5272534, a component manufactured by Cummins, is designed to play a role in the cooling system of heavy-duty trucks. This spacer is integral to maintaining the proper alignment and operation of the fan system, which is vital for effective engine cooling. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in engine components 1.

Function and Operation

The Fan Pilot Spacer operates within the engine cooling system by ensuring the correct positioning of the fan hub relative to the fan clutch. This alignment is crucial for the efficient transfer of rotational force from the engine to the fan, which in turn facilitates the movement of air through the radiator to cool the engine. The spacer interacts with both the fan hub and the fan clutch, ensuring that these components work in harmony to maintain optimal engine temperature 1.

Purpose of the Fan Pilot Spacer

The specific role of the Fan Pilot Spacer is to maintain proper fan-to-engine alignment. By doing so, it contributes to the efficient operation of the cooling system. Proper alignment ensures that the fan operates at the correct angle and distance from the radiator, which is important for maximizing airflow and cooling efficiency 1.

Key Features

The Fan Pilot Spacer is designed with specific characteristics that enhance its performance and durability. It is typically made from high-strength materials to withstand the rigors of heavy-duty truck operation. The design of the spacer may include features such as precise machining for accurate fitment and resistance to corrosion, which are important for longevity in demanding environments 1.

Benefits of Using the Fan Pilot Spacer

Incorporating the Fan Pilot Spacer into the engine cooling system offers several advantages. These include improved cooling efficiency due to optimal fan alignment, reduced wear on components by ensuring smooth operation, and enhanced overall engine performance as a result of consistent and effective cooling 1.

Installation Process

Correct installation of the Fan Pilot Spacer is important for its optimal function. The process involves ensuring proper alignment of the spacer between the fan hub and the fan clutch, following manufacturer-specified torque settings for fastening, and verifying that all components are securely in place. Attention to these details during installation helps to ensure the spacer performs its intended role effectively 1.

Troubleshooting Common Issues

Common problems associated with the Fan Pilot Spacer may include misalignment, which can lead to inefficient cooling, or physical damage to the spacer, affecting its ability to maintain proper fan positioning. Diagnostic steps may involve inspecting the spacer for signs of wear or damage, checking the alignment of the fan system, and ensuring that all fasteners are tightened to the correct specifications. Solutions may range from realigning components to replacing the spacer if it is found to be damaged 1.

Maintenance Tips

Regular inspection and maintenance of the Fan Pilot Spacer are recommended to prevent system failures. This includes checking for signs of wear or damage, ensuring that the spacer remains properly aligned, and replacing it according to the manufacturer’s guidelines or when signs of degradation are observed. Proactive maintenance helps to ensure the continued efficient operation of the engine cooling system 1.

Compatibility and Applications

The Fan Pilot Spacer 5272534 is commonly used in specific types of engines and truck models. It is important to use manufacturer-recommended parts to ensure compatibility and optimal performance. Cummins provides guidelines on the applications for which this spacer is suitable, emphasizing the importance of using parts that meet their specifications for the best results 1.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a history of producing high-quality engine components. The company’s product range includes a variety of parts designed for efficiency, durability, and performance. Cummins is recognized for its commitment to quality and innovation, making it a trusted name in the industry for those seeking reliable engine components 1.

Compatibility with Cummins Engines

The Fan Pilot Spacer, identified by part number 5272534, is a critical component in the cooling system of various Cummins engines. This part is designed to ensure proper spacing and alignment between the fan and the engine, facilitating efficient heat dissipation and maintaining optimal engine performance.

Compatibility with Specific Engine Models

The Fan Pilot Spacer is compatible with the following Cummins engine models:

- QSC8.3 CM850 (CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

Grouping by Engine Series

The compatibility of the Fan Pilot Spacer can be grouped based on the engine series:

-

QSC8.3 Series

- QSC8.3 CM850 (CM2850)

-

QSL8.9 Series

- QSL8.9 CM2150 L141

-

QSL9 Series

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

The Fan Pilot Spacer ensures that the fan is correctly positioned relative to the engine, which is essential for maintaining the integrity of the cooling system. This component is engineered to fit seamlessly into the specified engine models, providing a reliable and durable solution for maintaining engine temperature within safe operating limits 1.

Understanding the Role of Part 5272534 Fan Pilot Spacer in Engine Systems

Part 5272534, the Fan Pilot Spacer, is an integral component in the assembly and operation of various engine systems. Its primary function is to maintain the correct spacing and alignment between the fan and the pilot components, ensuring optimal performance and efficiency of the engine.

Integration with Engine Components

-

Fan Assembly: The Fan Pilot Spacer is positioned between the fan and the pilot, providing the necessary distance to allow the fan to operate without interference. This spacing is vital for the fan’s rotational movement and helps in maintaining the balance and stability of the fan assembly.

-

Pilot Mechanism: By securing the correct distance from the pilot, the spacer ensures that the pilot can engage and disengage smoothly with other engine components. This is particularly important in systems where the pilot controls the activation and deactivation of the fan, such as in variable speed fan systems.

-

Bearing Support: In many engine configurations, the Fan Pilot Spacer also supports the bearings that facilitate the rotation of the fan. Proper spacing provided by the spacer reduces undue stress on the bearings, prolonging their lifespan and ensuring consistent performance.

-

Thermal Management: Effective spacing between the fan and pilot also contributes to better thermal management within the engine. It allows for improved airflow, which is essential for cooling critical engine components and maintaining optimal operating temperatures.

-

Noise Reduction: The precise alignment and spacing offered by the Fan Pilot Spacer help in reducing vibrational noise. This is particularly beneficial in high-performance engines where noise, vibration, and harshness (NVH) are significant concerns.

-

Maintenance and Repair: During maintenance or repair procedures, the Fan Pilot Spacer simplifies the process of disassembling and reassembling the fan and pilot components. Its role in maintaining alignment ensures that reinstallation is accurate, reducing the likelihood of future malfunctions.

Conclusion

In summary, the Fan Pilot Spacer 5272534 plays a significant role in the efficient and reliable operation of engine systems by ensuring proper spacing, alignment, and support between the fan and pilot components. Its integration into the engine cooling system contributes to improved cooling efficiency, reduced wear on components, and enhanced overall engine performance. Regular maintenance and correct installation are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.