This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3002609 Fan Pulley is a critical component in commercial trucks, specifically within the engine cooling system. It facilitates the operation of the cooling fan, which is essential for maintaining optimal engine temperature and ensuring efficient engine functioning.

Basic Concepts of a Fan Pulley

A fan pulley is a mechanical device that connects the engine’s crankshaft to the cooling fan via a belt. It transfers rotational force from the engine to the fan, allowing the fan to draw air through the radiator. This process helps dissipate heat from the engine coolant, maintaining the engine within its optimal operating temperature range. The fan pulley works in conjunction with the fan clutch and radiator to regulate engine temperature effectively 1.

Purpose of the 3002609 Fan Pulley

The Cummins 3002609 Fan Pulley is integral to the engine cooling system. It ensures the cooling fan operates efficiently, maintaining optimal engine temperature. The pulley’s design allows for smooth and consistent rotation of the fan, which is essential for effective heat dissipation. By maintaining the engine at the correct temperature, the pulley contributes to the overall efficiency and reliability of the engine’s operation 2.

Key Features

The Cummins 3002609 Fan Pulley is characterized by several key features that enhance its performance and durability. Its design provides a secure fit on the crankshaft, ensuring stable operation. The pulley is constructed from high-quality materials that resist wear and corrosion, contributing to its longevity. Additionally, it may include features such as a balanced design to reduce vibration and noise during operation 3.

Benefits

The Cummins 3002609 Fan Pulley offers several advantages. It contributes to improved engine cooling efficiency, which is vital for maintaining engine performance under various operating conditions. The pulley’s durable construction reduces wear on associated components, leading to longer service intervals and lower maintenance costs. Furthermore, by ensuring efficient engine cooling, the pulley enhances overall engine performance and reliability 4.

Installation and Compatibility

Proper installation of the Cummins 3002609 Fan Pulley is crucial for ensuring correct fitment and function within the engine system. Installation procedures should follow manufacturer guidelines to ensure the pulley is securely attached to the crankshaft and properly aligned with the cooling fan and belt. Specific requirements or considerations may include torque specifications for fastening bolts and verification of belt tension to prevent slippage or excessive wear 5.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3002609 Fan Pulley involves inspecting for signs of wear, corrosion, or damage. Regular checks should ensure the pulley and associated components, such as the belt and fan clutch, are in good condition and functioning correctly. Common issues may include belt slippage or pulley misalignment, which can be addressed by adjusting belt tension or realigning the pulley as necessary. Troubleshooting steps should follow manufacturer recommendations to resolve any problems effectively 6.

Performance Enhancements

The Cummins 3002609 Fan Pulley contributes to overall engine performance by ensuring efficient engine cooling. Effective cooling helps maintain engine temperature within optimal ranges, which can positively impact fuel efficiency and engine longevity. By reducing the risk of overheating, the pulley plays a role in enhancing operational reliability, allowing the engine to perform consistently under various load conditions 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines, powertrains, and aftermarket parts designed to meet the demanding requirements of commercial vehicles.

Compatibility with Cummins Engines

The Fan Pulley part 3002609, manufactured by Cummins, is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the cooling system of the engines, facilitating the proper operation of the cooling fan.

N14 CELECT and N14 CELECT PLUS Engines

The Fan Pulley part 3002609 is compatible with the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their robust design and efficiency, and the pulley ensures that the cooling fan operates smoothly, maintaining the engine’s optimal temperature.

N14 MECHANICAL Engine

Similarly, the N14 MECHANICAL engine also benefits from the Fan Pulley part 3002609. This part is engineered to fit precisely, ensuring that the cooling fan functions correctly, which is crucial for the engine’s longevity and performance.

NH/NT 855 Engines

The Fan Pulley part 3002609 is also suitable for the NH/NT 855 engines. This compatibility ensures that the cooling system operates efficiently, preventing overheating and maintaining the engine’s efficiency.

Role of Part 3002609 Fan Pulley in Engine Systems

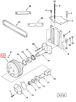

The part 3002609 Fan Pulley is integral to the efficient operation of various engine systems by facilitating the connection and rotation of several key components.

Integration with Assembly Fan Hub

The Fan Pulley interfaces directly with the Assembly Fan Hub, enabling the transfer of rotational force from the engine’s crankshaft to the fan. This ensures that the fan rotates at the necessary speed to provide adequate cooling for the engine.

Drive Mechanism

As part of the Drive system, the Fan Pulley is responsible for converting the rotational energy from the engine into mechanical motion. This is essential for driving the fan and maintaining optimal engine temperature.

Fan Operation

The Fan Pulley works in conjunction with the Fan to regulate airflow across the engine’s cooling fins. By adjusting the fan speed in response to engine load and temperature, the pulley helps maintain a stable operating environment.

Fan Arrangement and Fan Arrangements

In systems with multiple Fan Arrangements, the Fan Pulley ensures that each fan operates efficiently. It allows for synchronized rotation, which is vital for balanced cooling performance across the engine block.

Fan Drive Arrangement

Within the Fan Drive Arrangement, the Fan Pulley acts as a pivotal component. It manages the variable speed drive mechanisms, allowing the fan to adjust its speed based on the engine’s thermal needs, thus enhancing overall engine efficiency.

Fan Hub Interaction

The interaction between the Fan Pulley and the Fan Hub is designed to minimize mechanical losses and maximize cooling effectiveness. This synergy ensures that the fan operates within its optimal range, contributing to prolonged engine life and performance.

Conclusion

The Cummins 3002609 Fan Pulley is a vital component in the engine cooling system of commercial trucks. Its role in maintaining optimal engine temperature through efficient fan operation contributes to the overall performance, reliability, and longevity of the engine. Proper installation, maintenance, and understanding of its compatibility with various Cummins engines are essential for maximizing the benefits of this part.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Synthesis Lectures on Advances in Automotive Technology, Amir Khajepour, Springer, 2023.

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022.

↩ -

Engineering Mechanics: Statics, Libby Osgood, Gayla Cameron, and Emma Christensen, Creative Commons, 2024.

↩ -

General Information, Bulletin Number 4915552, Owners Manual.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Synthesis Lectures on Advances in Automotive Technology, Amir Khajepour, Springer, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.